Nikon MCAx S portable arm

MCAx S

Delivering a new level of portable scanning performance

MCAx S is a precise, reliable and easy-to-use 7-axis portable articulated coordinate measuring arm able to measure around and even inside large parts without constraints. It is the perfect partner for the industry leading ModelMaker H120 laser scanner and has seamless integrations to a variety of industry accepted metrology software suites.

The arm’s accuracy, capability and portability make it an optimal measurement companion in the metrology lab, on the shop floor or in the field.

Ranging in size from 2.0 to 4.5 m and with three performance levels to suit all budgets or application accuracy, it is compatible with tripods and other bases allowing freedom to select the right mounting for the task in hand. Infinite rotation and 7-axis freedom of movement give unrestricted reach in and around parts. Thermal stability and advanced encoder technology eliminate warm up, reducing setup and inspection time.

The MCAx S offers true multi-probing. Alongside the scanner, tactile probes can be used in parallel to measure geometric features or hard to reach areas. Advances such as automatic intelligent pre-selection of scanner or probe depending on type of measurement enhances ease-of-use for full remote operation of the solution.

Key benefits

- ISO 10360-12 certification

- Thermal stability and advanced encoder technology eliminate warm-up

- Infinite rotation and 7-axis freedom of movement for unrestricted reach in and around parts

- Clear system feedback with integrated visual, audio and haptic indicators

- Safe and secure locking and relocating

- Versatile mounting with magnetic bases, vacuum bases, stands or tripods

- Optional wireless usage for up to four hours at full scanning speed

Intelligent multi-probing

Intelligent multi-probing

Seamless integration of the ModelMaker H120 laser scanner with the MCAx S arm provides high-performance non-contact data capture. With the scanner positioned away from the probe, tactile accessibility and ability reach into tight spaces is optimal.

Automatic pre-selection and switching between scanner and probe enhances productivity. Simply choose to probe a feature and the system automatically selects the connected probe. Choose to scan a surface or a feature and the system automatically selects the ModelMaker H120.

The ergonomic handgrip, user configurable multi-functional buttons and repeatable, auto-recognised scanner and probe mounting provide comfortable and easy operation. The integrated LED wrist screen gives status updates close to the point of measurement and can remotely invoke useful tools such as accuracy verifications.

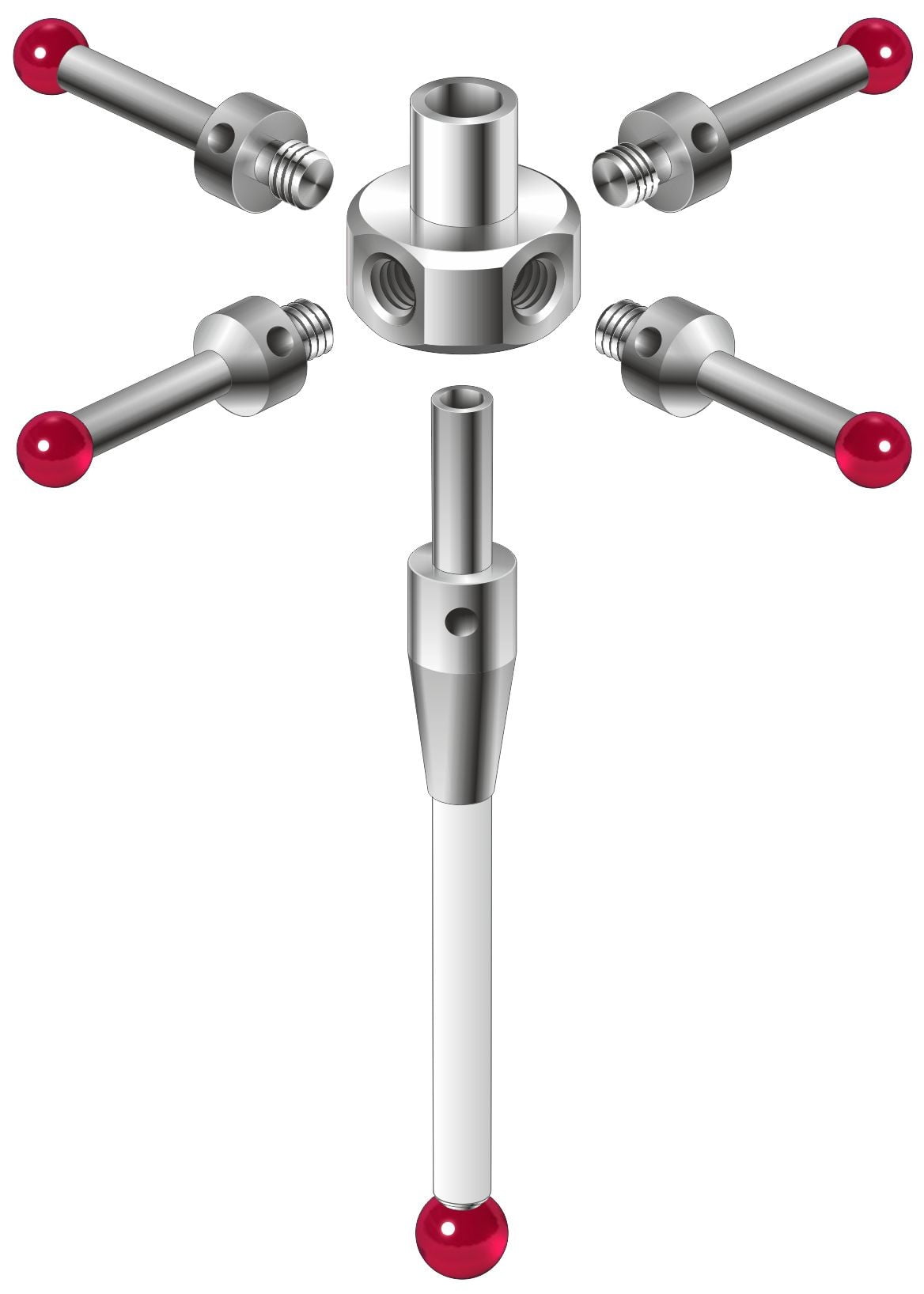

A large range of straight and angled probes as well as touch-trigger probes is available for tactile versatility, complementing the standard three probes included with every system.

ISO 10360-12 certification

Every MCAx S arm supplied with a comprehensive certification to the ISO 10360-12:2016 standard, giving clear understanding of the overall tactile probing performance to meet modern industry expectations.

| Length measurement error, unidirectional Defines the maximum permissible error of over 100 uni-directionally measured lengths, representing the global (or volumetric) accuracy. |

|

| Probing form error, tactile Defines the maximum permissible error in form measurement of a sphere, representing probed feature noise. |

|

| Probing size error, tactile Defines the maximum permissible error of sphere diameter, representing probed feature size accuracy. |

|

| Articulated location error, tactile Defines the maximum permissible error in sphere location measured from different arm poses, representing probed feature repeatability. |

Precision measurements, immediately

Precision measurements, immediately

High performance specifications such as length accuracy from just 0.029 mm and feature size from just 0.010 mm can be realised without waiting for the system to reach working temperature. The MCAx S arm performs within specification straight from the box.

Productivity is paramount and accurate measurements are available immediately after set-up, either tactile or using the temperature compensated ModelMaker H120 laser scanner.

System warm up is unnecessary thanks to the negligible thermal expansion properties and stiffness of high-tech carbon fibre materials along with the rigid structural design offering temperature stability and long-term mechanical strength.

Probe and scanner mounting is repeatable and each specific probe’s calibration parameters are automatically used so no time is wasted.

To save time, absolute encoders remove the need to reference every axis and simple plug and play connectivity means there is no need to reconfigure default PC Ethernet or Wi-Fi network settings.

Designed for safe and stress-free handling

The MCAx S arm features many design elements improving accuracy, ease-of-use and safety such as rotating grips and secure locking.

- S++ and S+ model users benefit from reduced inertia thanks to low resistance rotating grips.

- Integrated counterbalance for lightweight freedom of movement and minimal user fatigue.

- Secure locking of the arm for reassurance during repositioning between measurements.

- Optimised wrist docking for a safe but ready-to-measure position protects the scanner and probe.

User feedback

User feedback

For total clarity of measurement activity and system status in any environment, the MCAx S provides easy to interpret visual, audio and haptic indications:

- Bluetooth® connectivity for external speakers or headphones to enhance the volume of the already comprehensive range of built in acoustic prompts.

- Simple multi-coloured visual pictograms on the arm base display connectivity and power status.

- Haptic feedback via wrist vibration indicates approach of a joint hard stop.

- Large, easy to read on screen messaging.

The integrated wrist screen enables users to monitor status without looking away and can remotely invoke probe calibration and accuracy checking without touching the PC.

Wireless scanning

Wireless scanning

With the optional Wireless Control Pack, high-speed Wi-Fi connectivity and dual hot-swappable batteries augment the system with true cable-free usage. Scan wirelessly for up to 4 hours using the ModelMaker H120 with no reduction in data speed or quality.

For demanding applications requiring total wireless operation over extended periods, additional batteries and external battery charging capability is available.

Standard Control Pack connectivity included with every system gives robust single cable Ethernet Gigabit data transfer and AC power.

Mobile convenience

Mobile convenience

Incorporating all the essential hardware elements needed for table set up, measurement and accuracy verification, the precision cut foam inside the shock-proof wheeled flight case gives optimal protection to both the ModelMaker H120 scanner and MCAx S arm.

A fitted dust cover, supplied with every system, protects and keeps the solution clean when not in use.

Mounting versatility

Mounting versatility

The integrated 3.5 in x 8 adapter gives freedom to choose exactly the right mounting for the application, providing secure installation within seconds:

- Bolt-down, magnetic or vacuum bases for table-top mounting

- Heavy duty mobile or fixed stands for shop floor mounting

- Portable tripods for measurement on different sites

Intelligent multi-probing

Intelligent multi-probing Precision measurements, immediately

Precision measurements, immediately User feedback

User feedback Wireless scanning

Wireless scanning Mobile convenience

Mobile convenience Mounting versatility

Mounting versatility