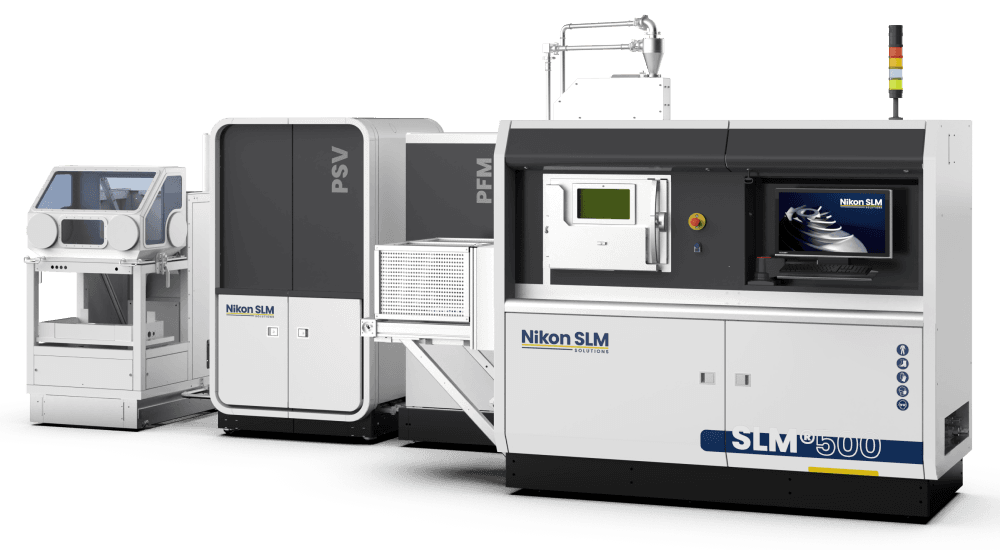

Nikon SLM Solutions - SLM®500

Maximize productivity and performance with the SLM®500. Engineered for serial production, this versatile system offers unparalleled speed, precision, and scalability. Whether you’re producing complex prototypes or large-scale components, the SLM®500 delivers tailored solutions for industries seeking to elevate their manufacturing capabilities and stay ahead of the competition.

Accelerated Production

The SLM®500 integrates lasers independently or in parallel, boosting build rates by up to 90% compared to twin laser configurations, ensuring rapid production turnaround.

Enhanced Safety

Featuring a wear-resistant closed-loop powder handling strategy, the SLM®500 separates machine operators from powder, incorporating an automated powder sieve and supply to ensure operator safety and lower operational costs.

Minimal Downtime

With an exchangeable build cylinder designed for serial production, the SLM®500 enables the shortest fire-to-fire times, reducing machine downtimes to a less than an hour turn-around and maximizing productivity.

Streamlined Workflow

Advanced software compatibility, and intuitive interface design on the SLM®500 simplify operation and enhance user experience, ensuring a seamless workflow from design to production.

Cost Efficiency

The SLM®500 minimizes material wastage through precise laser control and powder handling mechanisms, reducing production costs and maximizing the efficiency of metal additive manufacturing. Plus, our Permanent Filter Module arrives as standard.

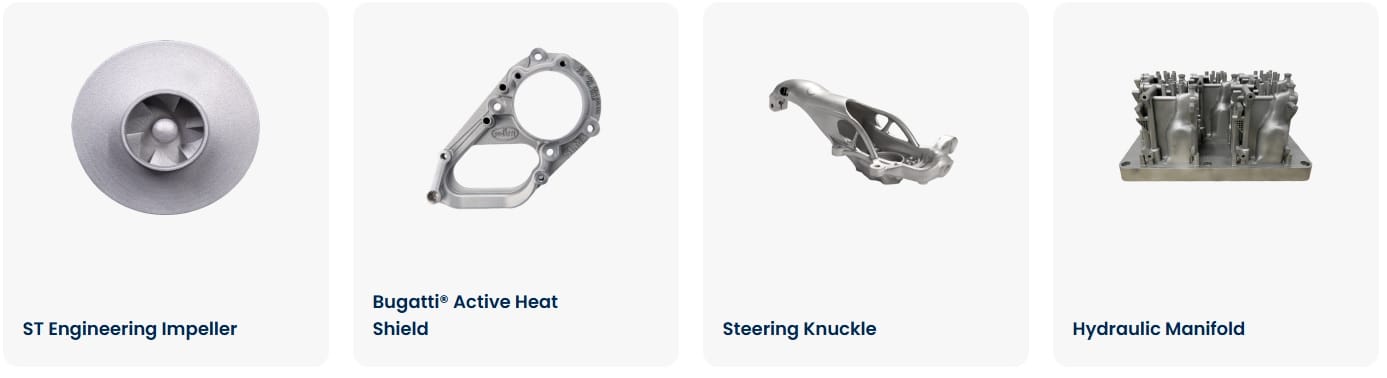

Versatile Applications

With its large build volume, the SLM®500 accommodates a wide range of part sizes and geometries, offering versatility for diverse manufacturing needs.

Precision Engineering

Utilizing high-precision laser technology and advanced thermal management systems, the SLM®500 ensures exceptional part accuracy and surface finish, meeting the most stringent quality standards.

Scalability

Designed for scalability, the SLM®500 allows seamless integration into existing production lines and facilitates the expansion of additive manufacturing capabilities to meet growing demand.

Customization Potential

The SLM®500 offers design freedom with its ability to produce complex geometries and lightweight structures, empowering manufacturers to innovate and customize products with ease.

Reliability Assurance

With robust construction and rigorous quality control measures, the SLM®500 delivers consistent performance and reliability, ensuring uninterrupted production and peace of mind for operators.