INVERTED MACHINING CENTER MODIG IM-6/ IM-8/ IM-10

The IM-machine series was born to meet today’s manufacturing signified by ever more closely geometric part tolerances, part and component complexity, and faster production times within the industry. The machines processing from below transforms the way we will think about generic 5-axes and component machining. So, let us think inverted.

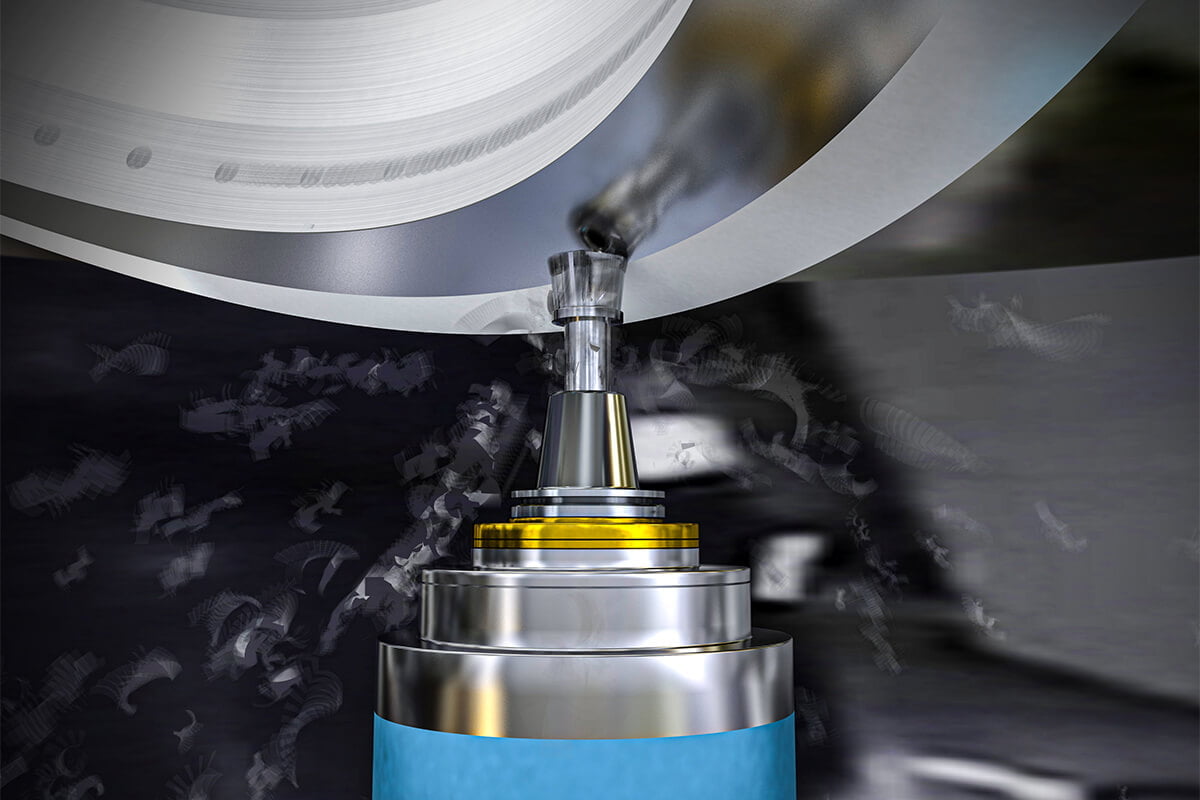

With a patented design, a single spindle with up to 200 hp (150 kW) working from below, this high-speed inverted machining center sets a new standard for 5-axes machining. Extreme fast cut-to-cut times make the machine suitable for industries characterized by large volumes, quick lead times, and high complexity. A stable machine with a cast iron base around the structure, makes the machine extremely rigid, enabling the tool to work with extreme precision. Working inverted means easier chip evacuation with less consumption of coolant. The gravity makes the chips fall with a natural flow from the work piece and the working area. The stability, together with the excellent optimized chip handling system, yells for higher performance.

EASIER CHIP EVACUATION AND DESIGNED FOR OPTIMAL USE OF FLOOR SPACE

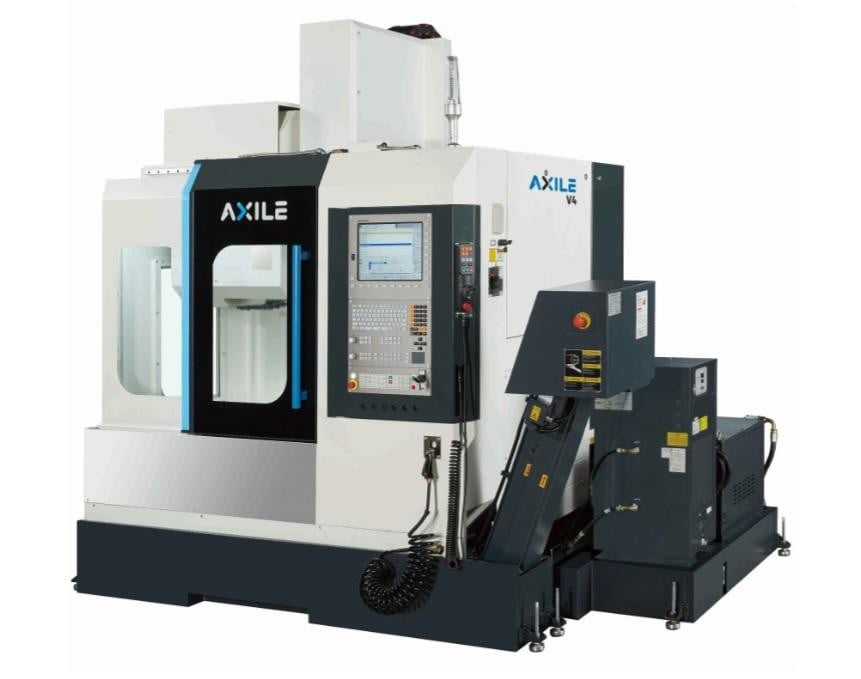

The choice of IM-6, IM-8, or IM-10 depending on the size of work piece you are machining. The trunnion tables are available in the sizes of 25”, 32” or 40” (630, 800, or 1,000 mm) which gives a total of max part size of 37” x 30” x 22” (970 x 750 x 550 mm) and an interference diameter of 47” (1,200 mm). The IM machine series are designed for optimal use of floor space where the design makes it possible to place the machines side by side. The chip conveyor is placed in the back of the machines with easy access for chip handling. Loading of material and unloading of parts, take place either manually from the front or by a pallet system, or with overhead loading. In this way the machines can efficient be used for high productivity in your production lines. Options for pallet system, robot loading, and overhead loading are available.