Special Tools

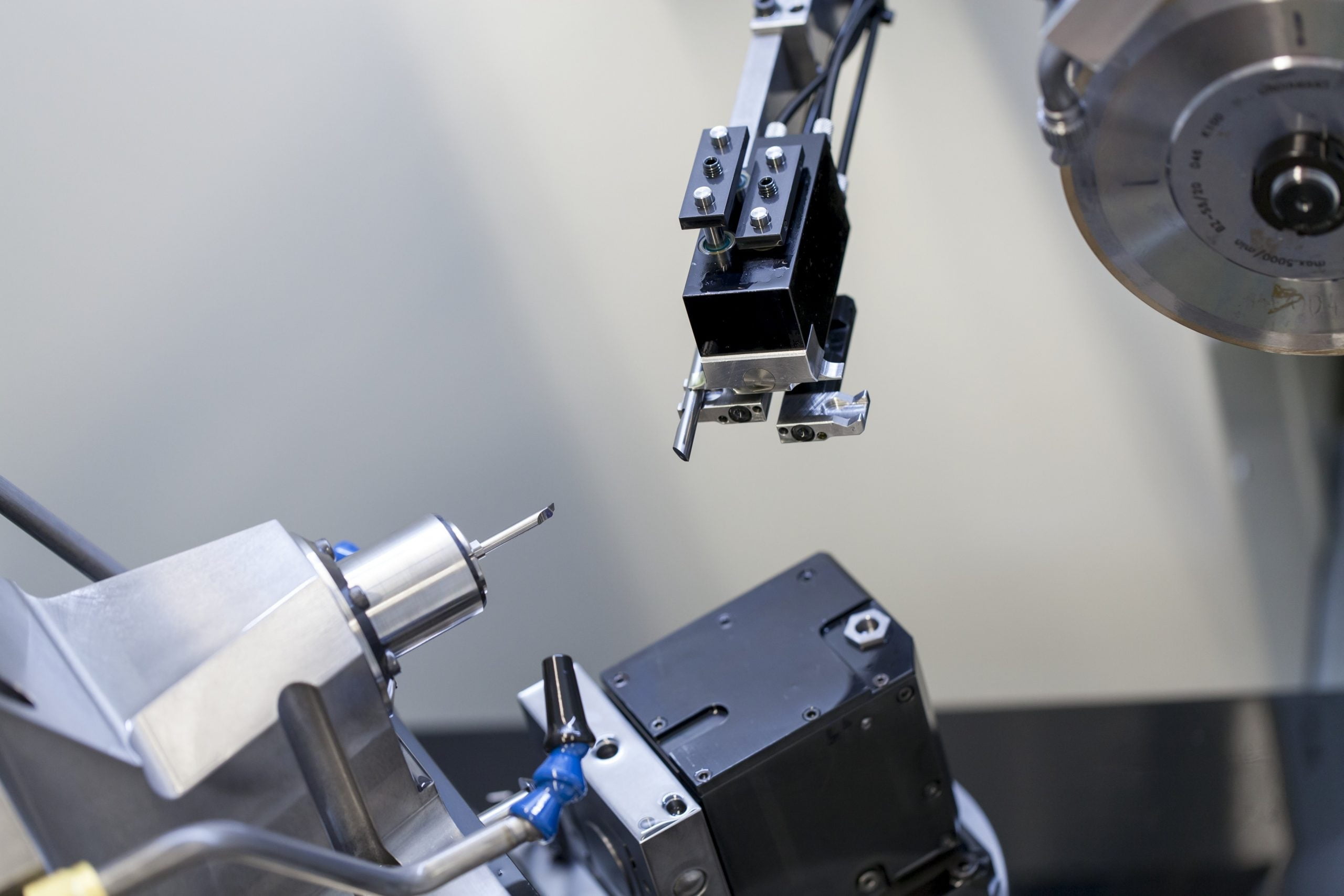

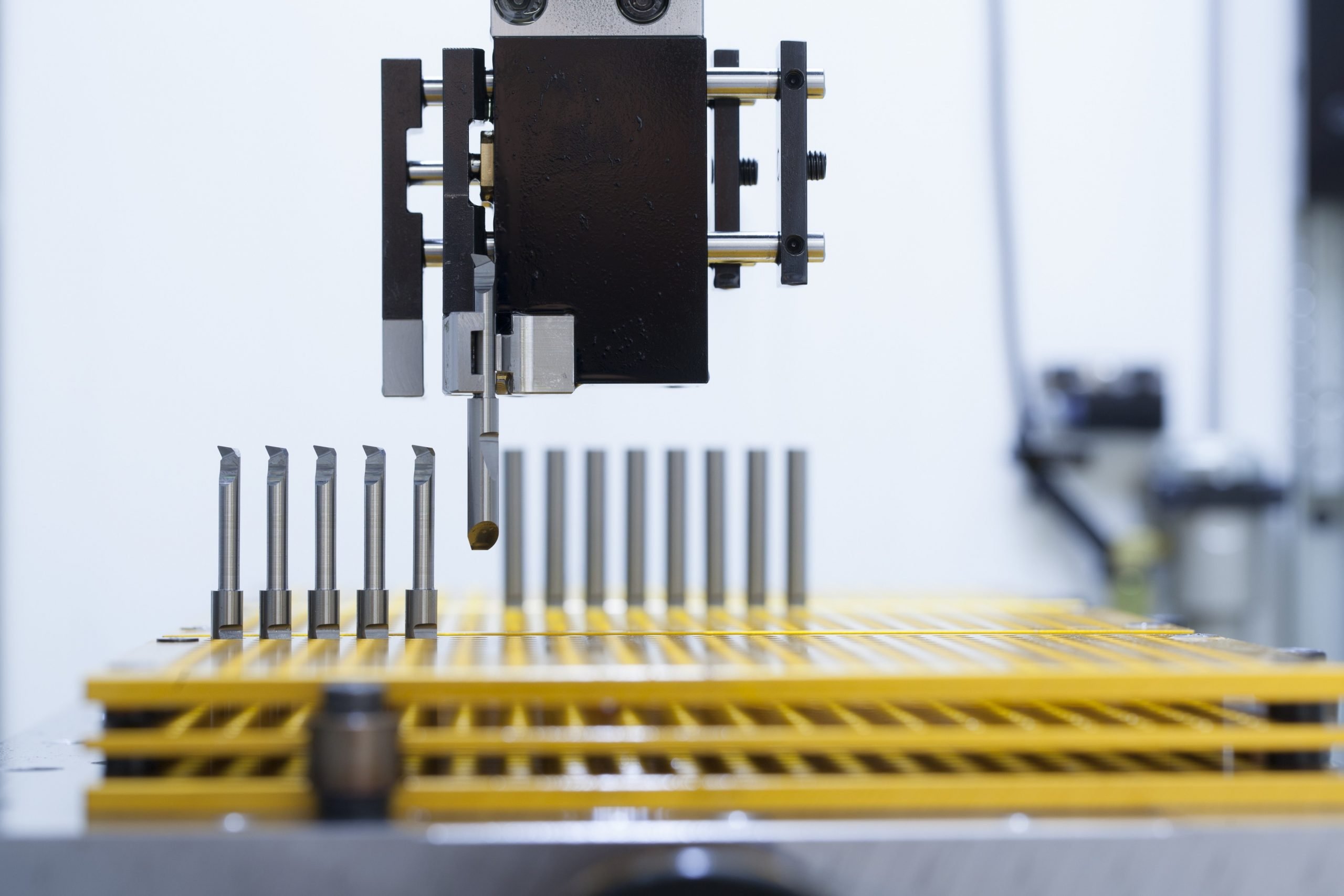

We specialize in the production of profile inserts and tools for inside turning and recessing. We are able to use many grades of carbide, CERMET and CBN. Profile inserts offer great time and financial savings. We are able to replace multiple tools at your production by a single special profile insert to create the same product. Tools for inside turning can be used from a hole diameter 2.5 mm, even machining various recess shapes inside such a hard to reach places.

Production process when creating a special tool:

1) receiving an inquiry

2) tool design according to customer’s documentation

3) price quotation and customer’s production approval

4) tool production and coating

5) special tool delivery.

The complete process takes 1 – 2 weeks.