Laser marking system with rotary table - LASIT RotoTower

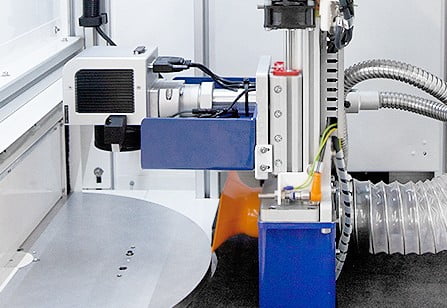

The machine has a two-position index table with a 20mm thick Fibral Aluminium disc. The disc has 2 centering holes for the templates and 2 threads in correspondence with the two stations. The holes are ø8H7 with tempered collets while the threads are M8 with Helicoil.

The index table has a mechanical (non-pneumatic) cam and provides extremely accurate positioning and rigidity. Positioning time from station to station is approximately 1 second and can be adjusted with the variable-speed drive.

Rotary table for marking in masked time

The rotary table is the centre piece of the machine’s mechanical components and is what makes its results precise and repeatable over time. At Lasit, we pay close attention to its selection, assembly and test-runs. The mechanical cam mechanism provides:

1. Extreme rigidity thanks to high diameter bearings

2. Precision and repeatability of positioning at 100μm on the table’s outer edge

3. Rotational speed (greater productivity) thanks to the control with inverter developed by Lasit

Welded steel frame

Rototower is extremely rigid and ergonomic: its frame was developed entirely in welded steel. After thermal expansion, the frame is carefully finished to create support surfaces for screws and sliding guides, resulting in the following advantages:

- Greater acceleration of the axes without vibrations;

- Dimensional stability over time;

- Rigidity in the event of moving the machine and/or accidentally bumping into it.

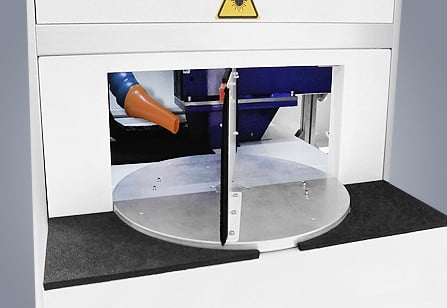

Lateral door for presetting

RotoTower has an interlocked door for accessing the marking compartment so as to easily setup the machine and to mark individual parts, equipment or small runs that do not warrant creating the mounts for the rotary table. The door is fitted with an inspection window, allowing you to observe the marking process in complete safety.

Download the brochure