Laser marking station TowerMark X

Product Description

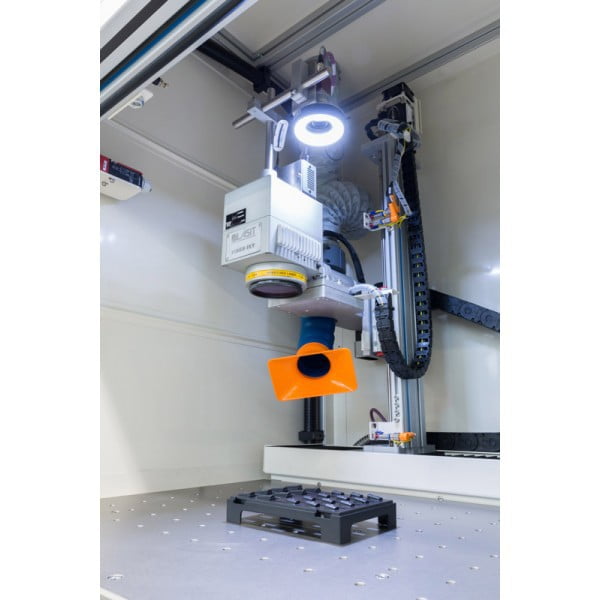

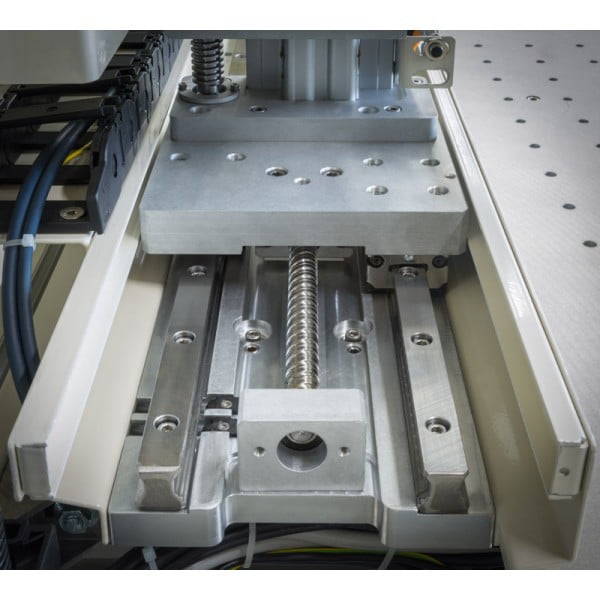

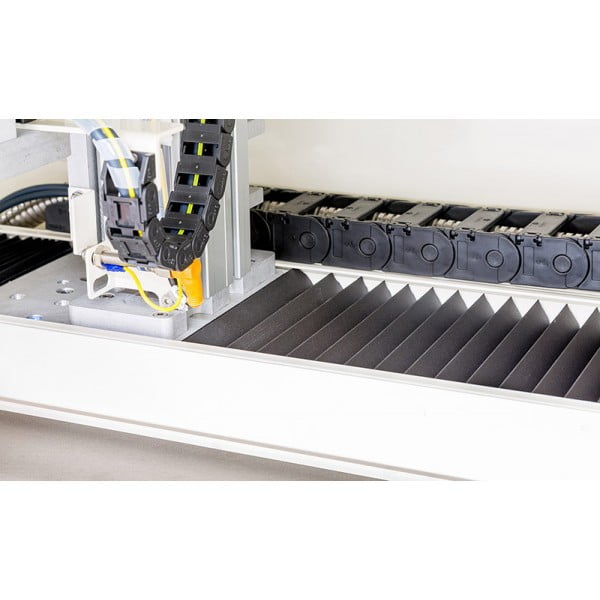

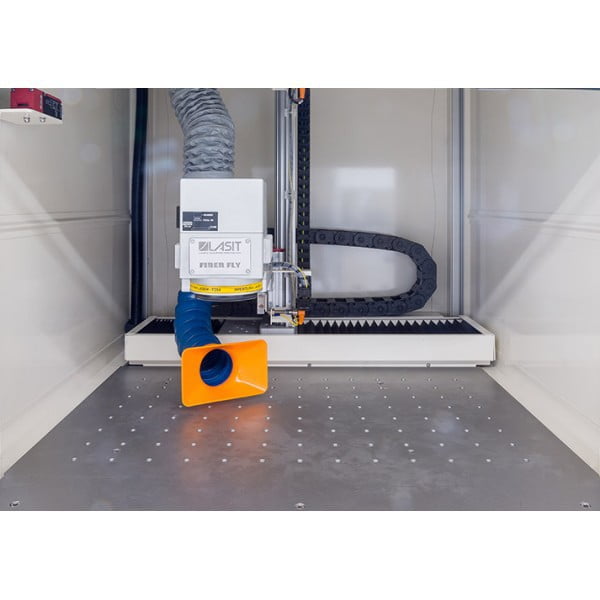

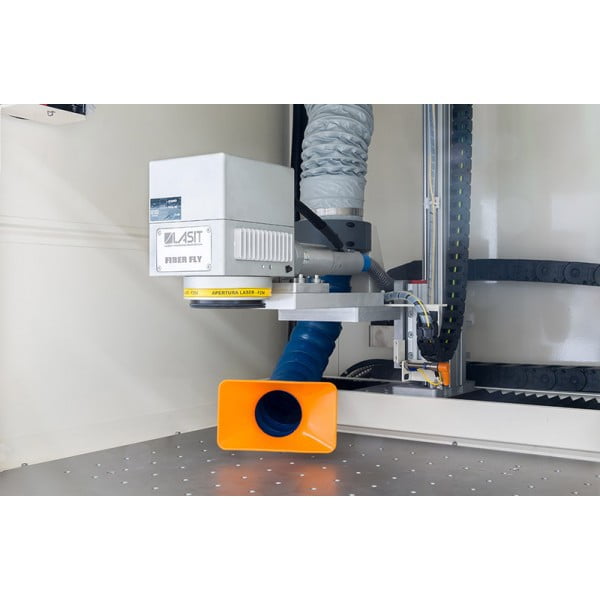

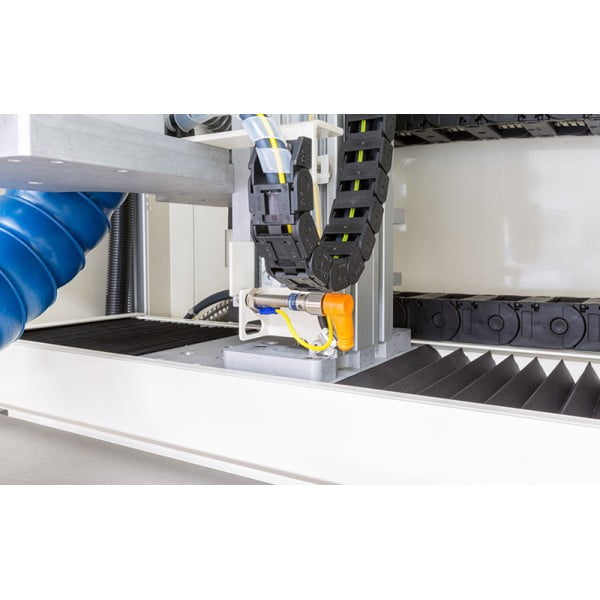

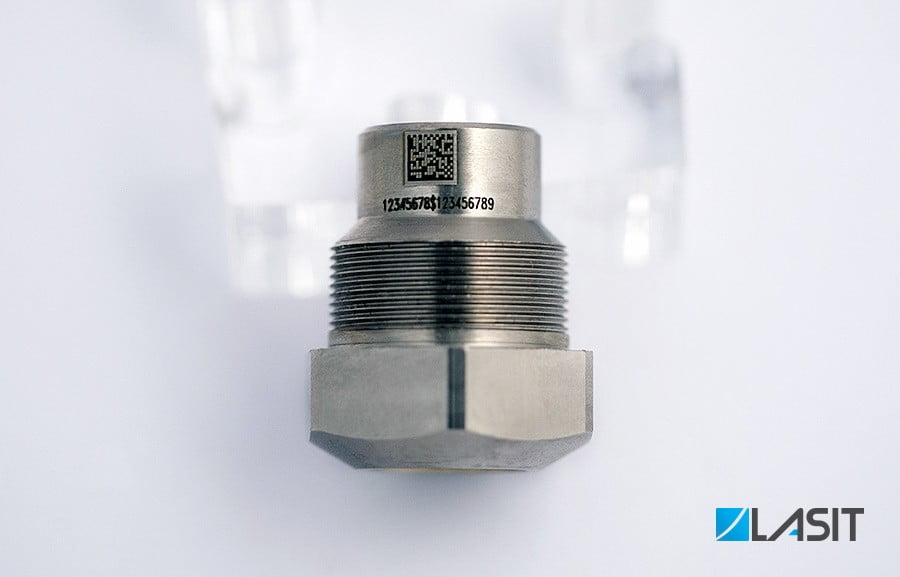

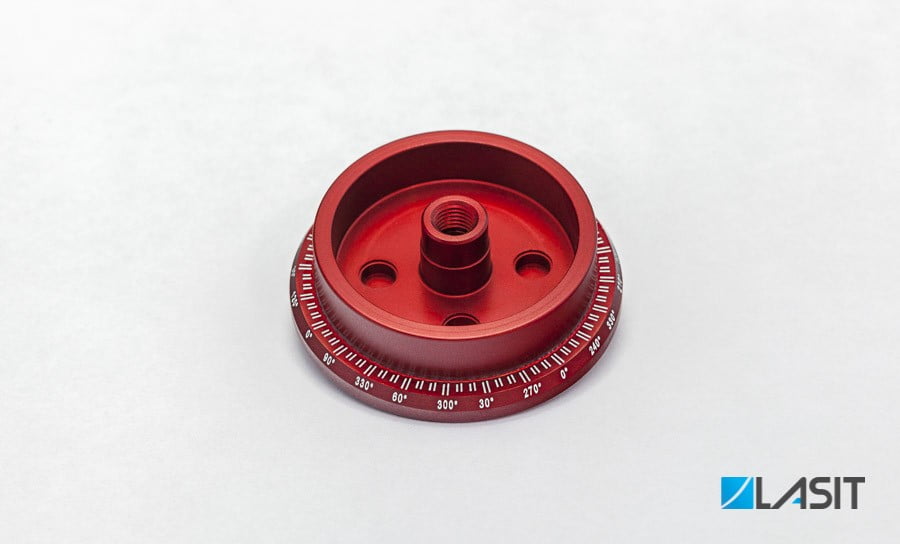

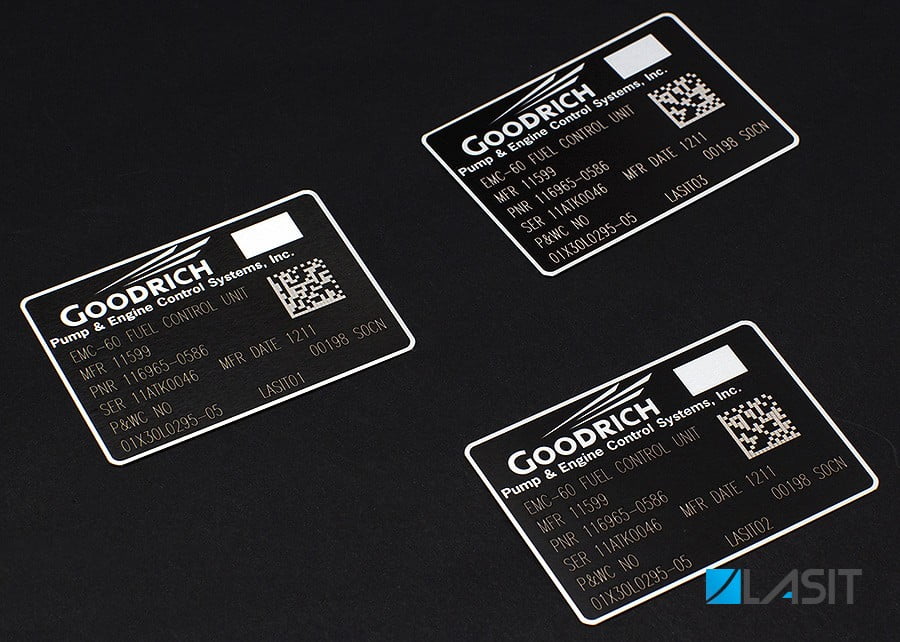

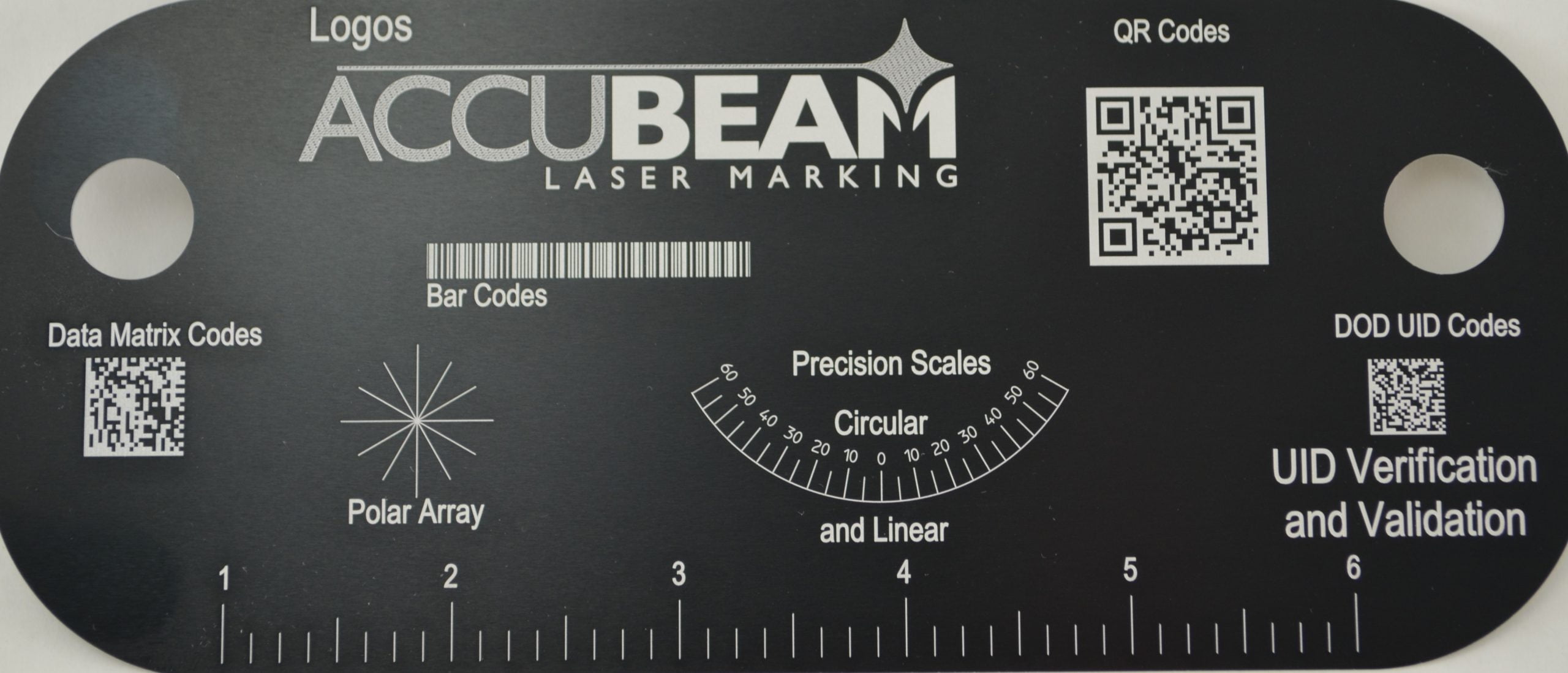

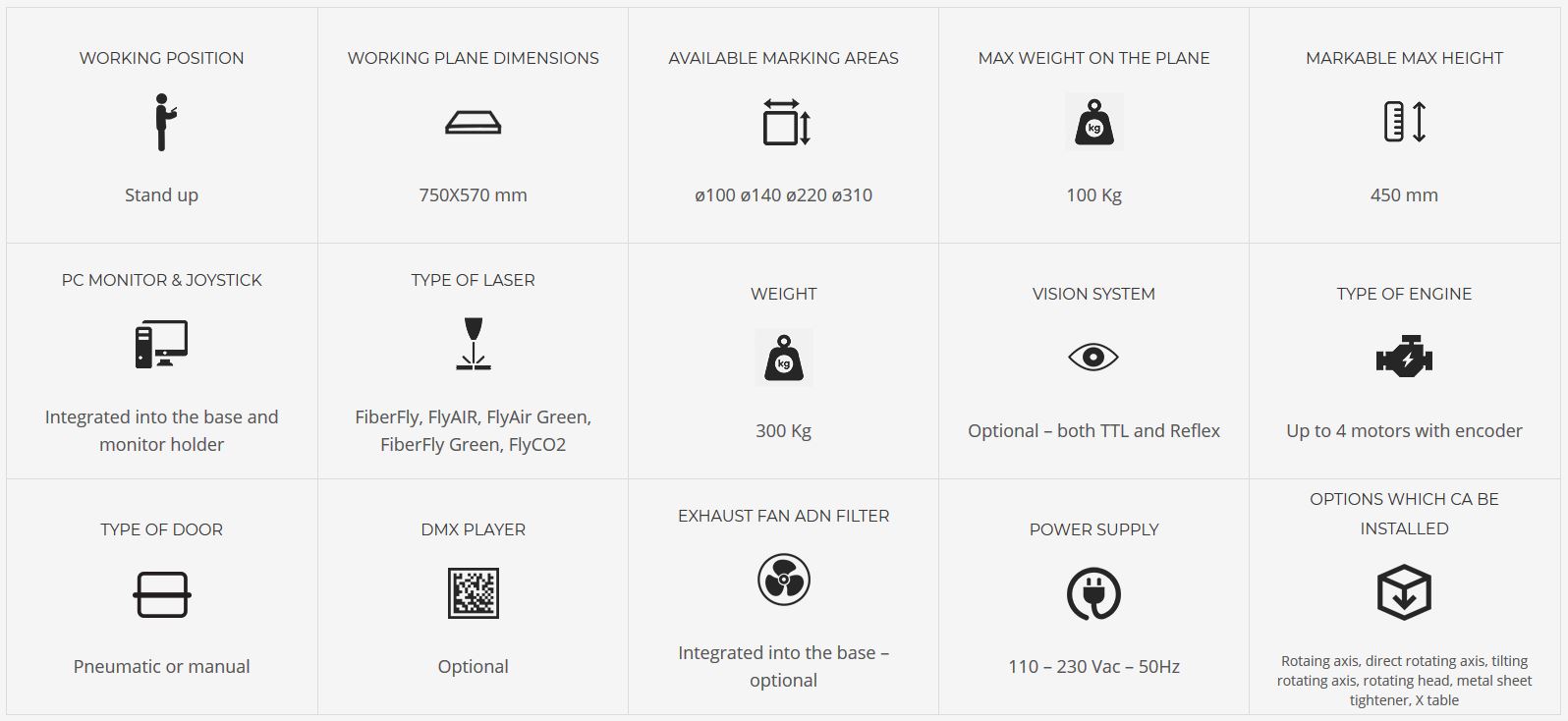

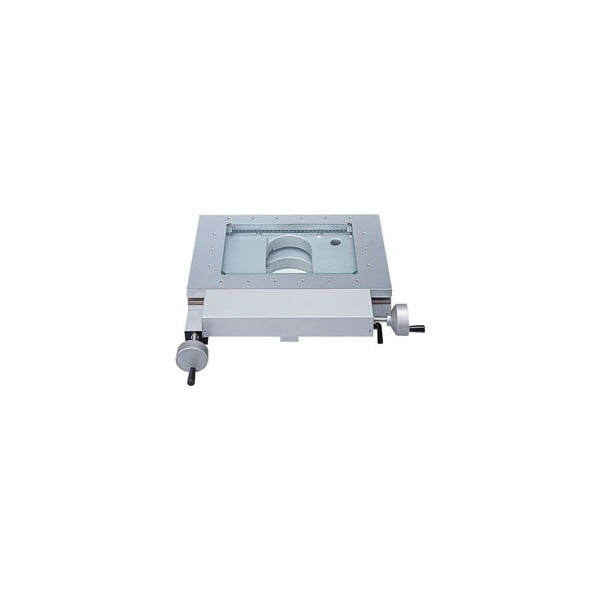

The laser marker TowerMarkX is extremely versatile and configurable according to different needs and can be equipped with different types of laser sources depending on the type of material to be marked (Co2, Fiber, FlyAir, FlyAir Green, Green Fiber, UV). It offers a good balance between the working and the footprint area of the machine. Maintaining a stand-alone formula and the possibility to integrate internally different accessories according to requirements. The work plan is 750x500mm, all-aluminum hard anodized scratch-resistant drilling step to facilitate the positioning of the parts and thus speed up the process of pre-marking. The main characteristics of the marker TowerMarkX is an innovative system for moving the laser in X and Z that allows to mark individual parts of various pallet sizes up to 600x170mm without cluttering the working area of the marking in such a way as to fully exploit it. XZ Axes are fully managed by the marking software FlyCAD and motors are integrated with encoder and can also be managed by a joystick for the immediate search of the fire with SmartFocus technology. In this way, the operator can quickly find – both on flat surfaces but especially on parts that have complex geometries, with particular curves or corners the correct position for an optimal marking. The door can be manual or pneumatic wide inspection window that provides an excellent view of the marking. You can have as an option a comfortable drawer to speed up the loading and unloading of the details to be engraved. Inside the laser marking cabin can also be installed a rotary axis for marking cylindrical parts continuously, a rotating head for marking on special inclined parts up to 90°, a vision system for the recognition of details and a Datamatrix Reader for quality verifications.