Mobile X-Ray inspectiopn Visiconsult Xplus Mobile

Mobile X-Ray inspectiopn Visiconsult Xplus Mobile

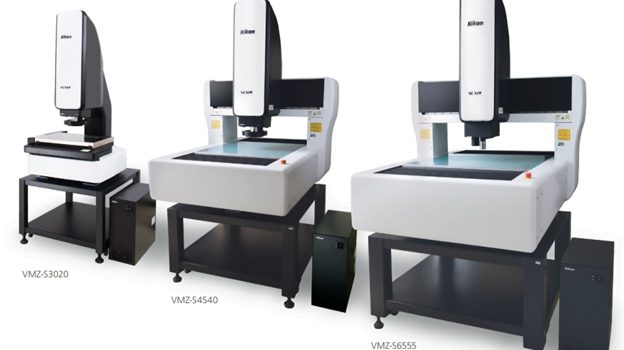

In some cases stationary systems are not feasible: Typical applications are in-field inspection of pipelines, power-plants, factories or spot checks. Operators look for common wear and tear faults like corrosion or weld-cracks.

Many industries like oil and gas, aerospace, defense, construction and energy are relying on regular spot checks to prevent catastrophes with severe consequences. Requirements of such mobile systems are easy handling, lightweight construction, flexible inspection usage, long battery runtime, wireless operation and durability. The VisiConsult mobile palette was developed parallel to our security systems that are certified by the German Army and the NATO. This ensures a high mobility and very reliable design.

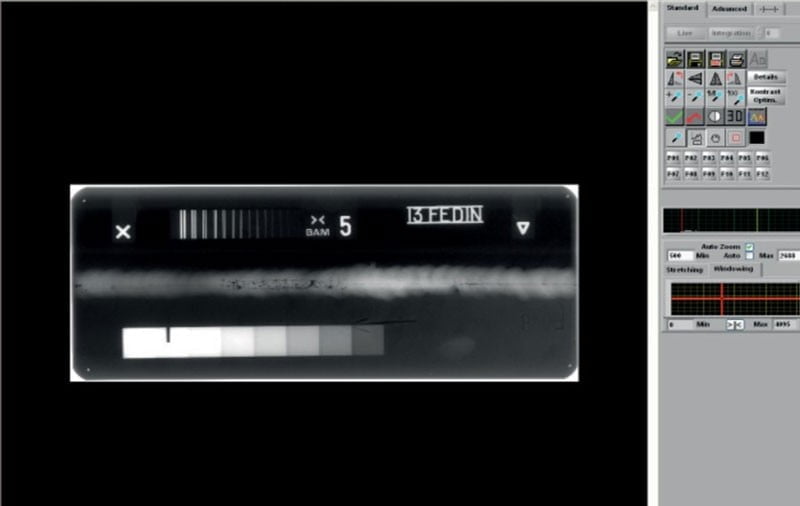

To maintain high usability the complete setup can be customized to customer requirements. In terms of image sources operators can choose from a broad palette of Flat Panel Detectors (FPD/DDA), the completely integrated Dürr CR portfolio and the possibility to use film digitizers. The X-ray source can also be freely determined depending on the application: Mobile X-ray tubes, semi-stationary tubes or isotopes are common choices.

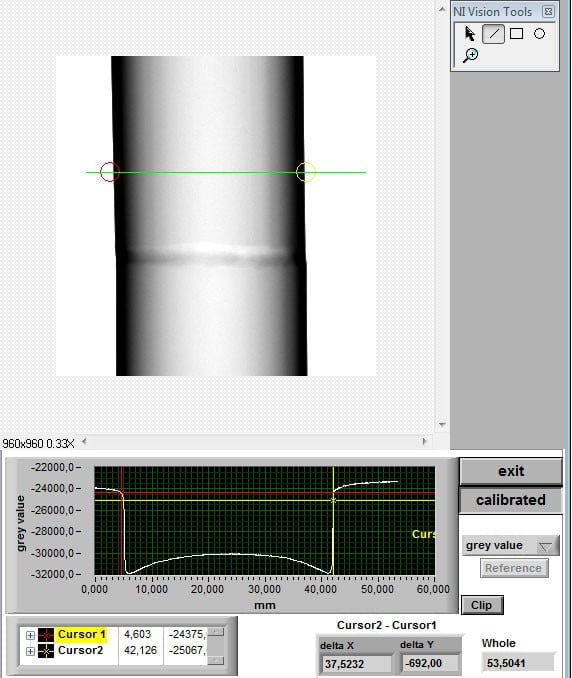

- Detection of welding defects like porosities, inclusions, cracks and other flaws;

- Highly mobile in a backpack or Peli-case setup for convenient transportation;

- Choice of multiple image sources, like CR, DDA/FPD, Film;

- Highlight defects with the powerful Xplus image enhancement tools;

- Proven industrial design to endure even demanding conditions;

- X-ray sources: Mobile tubes, flash tubes or isotopes;

- Proven industrial design to endure even demanding conditions;

- Convenient digital archiving of X-ray images and inspection results.

All solutions are proven in field and are designed in a rugged industrial design to endure the demanding conditions of mobile inspection jobs. The systems are highly mobile and can be transported in backpacks, Peli-cases or other convenient ways. To optimize the efficiency VisiConsult developed plenty of helpful accessories to speed up the inspection process: Holders, tripods, diaphragms and other gadgets are available.

The combination of different technologies like DR, CR, film or X-ray sources like mobile tubes, flashtubes or isotopes is highly dependent on the inspection task. As standards often require to archive the inspection results for multiple years or the end-customer demands the results to be delivered huge physical archives have to be built to store films accordingly. Using the Xplus storage tools the X-ray images can be archived conveniently to image databases or DICONDE files conforming to international standards. This saves time, space and money.

Download the brochure