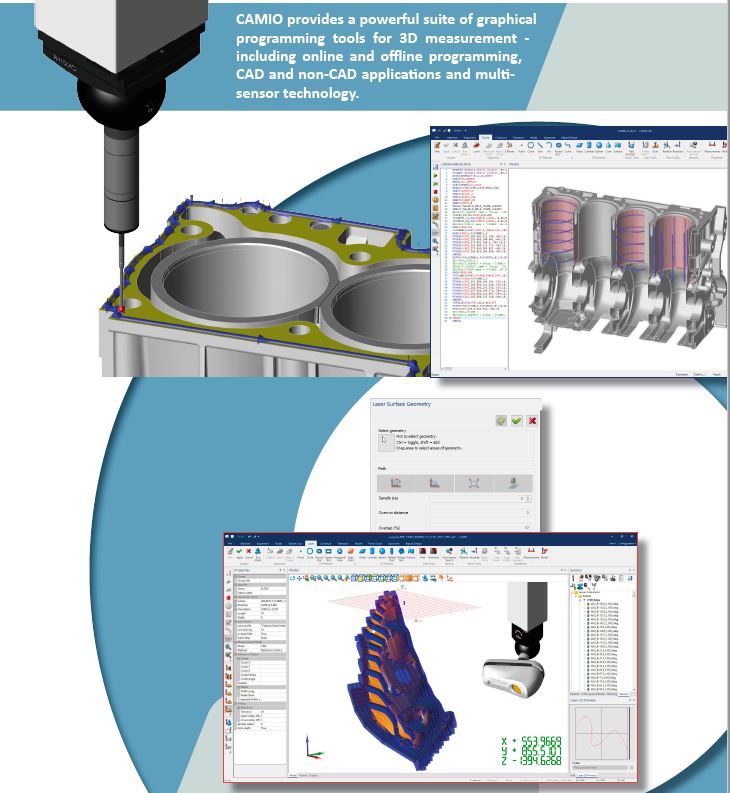

LK CAMIO Multi-sensor CMM software

LK CAMIO Multi-sensor CMM software

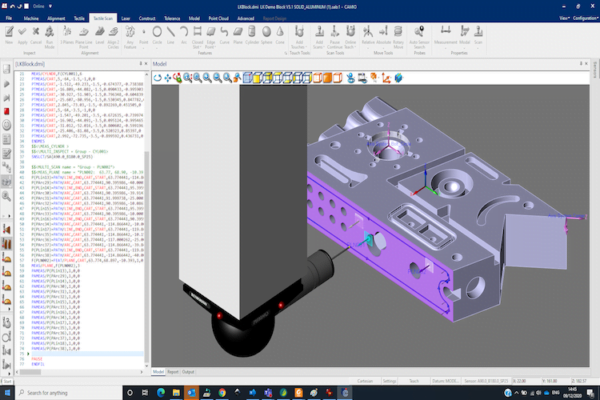

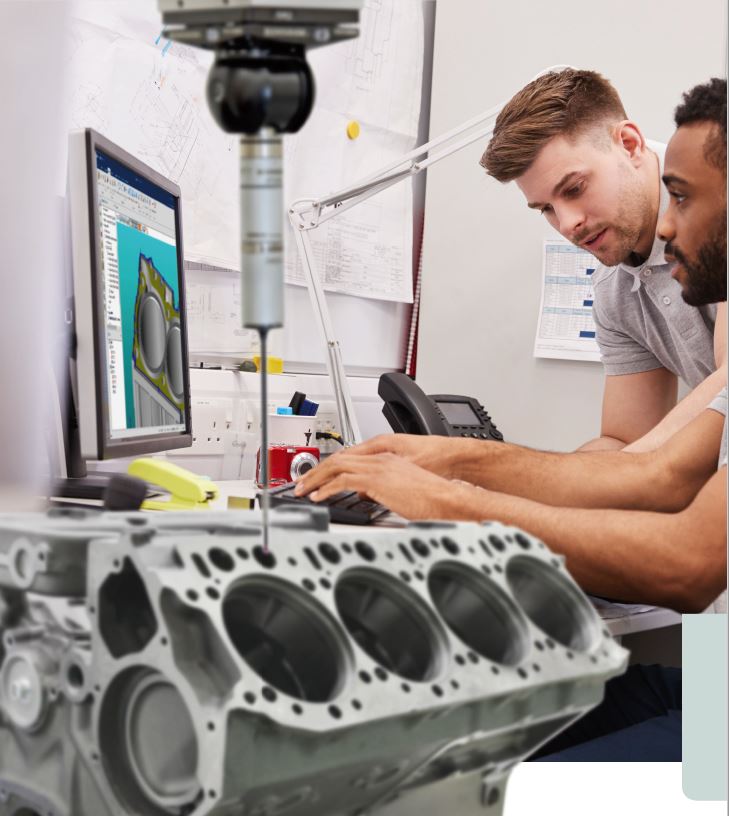

CMM inspection is faster and easier with CAMIO

Proven in the most challenging application environments CAMIO is the CMM software of choice for many of the world’s largest manufacturers. By leveraging the productivity benefits of CAMIO, manufacturers can focus on accelerating lead times and improving product quality while reducing costs. CAMIO’s interoperability across CMM platforms, sensor technology and manufacturing sites, is a unique advantage which guarantees the sustainability of your investment in software and inspection programs.

COMPLIANCE

CAMIO has been verified according to following organisational CMM standards:

- DMIS 5.3 (Dimensional Metrology Standard Consortium)

- PTB 5.32 CMM software algorithms (Physikalisch‐Technische Bundesanstalt)

- ISO 1101:2017 Geometric Dimensioning and Tolerancing (International Organization for Standardization)

- ASME Y14.5:2018 Dimensioning and Tolerancing (American Society of Mechanical Engineers).

Key benefits:

- Select the right sensor for the job to get better insights while reducing overall cycle time

- Easily write your inspection program based on the CAD model

- Proof programs offline with collision detection and measurement simulation

- Analyze product conformance through graphic CAD comparison for features and surfaces

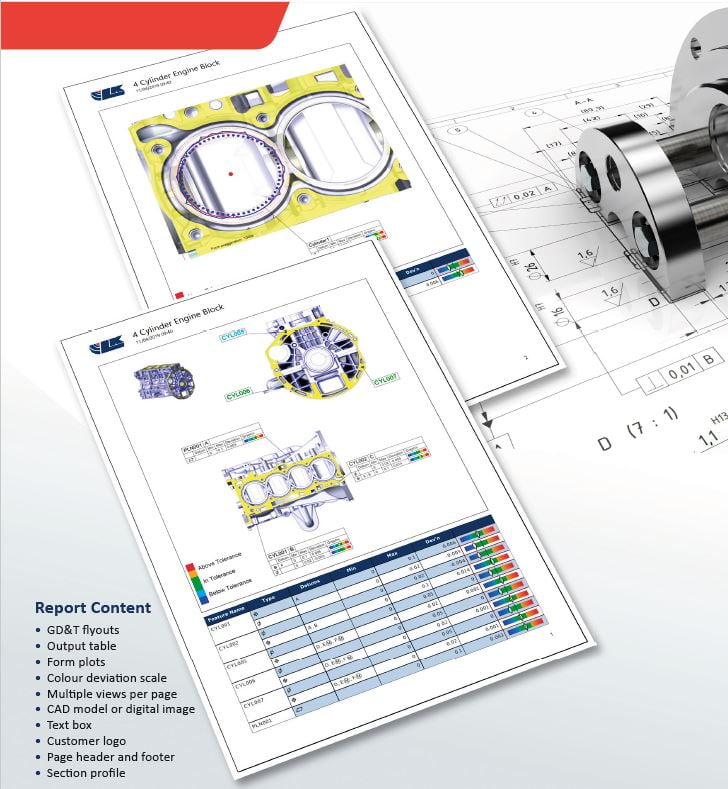

- Speed up the decision process with instant reporting

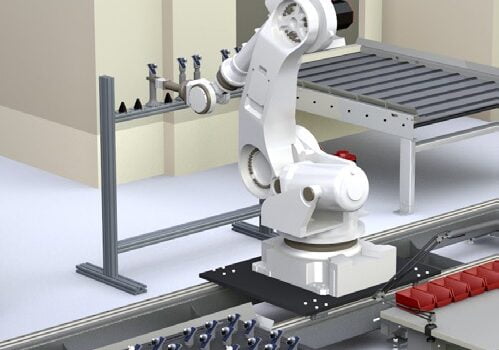

- Increase productivity by automating the inspection processes

Highlights

- Improved Measurement Strategies and new streamlined workflow, resulting in greater productivity when programming.

- New default Measurement Strategy for point, circle, line, plane, edge, cylinder, slot and curve features.

- Copy a Measurement Strategy to quickly apply multiple measurement techniques to a feature.

- Probe Path simulation now displays the measurement mode, touch points, intermediate moves and connecting moves.

- The inspection program Run Number is now stored with the measurement results in the Inspection Database.

- Multiple bilateral position tolerances can now be created more efficiently in a single operation.

- Added support for unequally disposed tolerance bands according to the latest GD&T standards.

- The coordinates of taught GOTO moves can now be rounded using a user-defined number of decimal places.