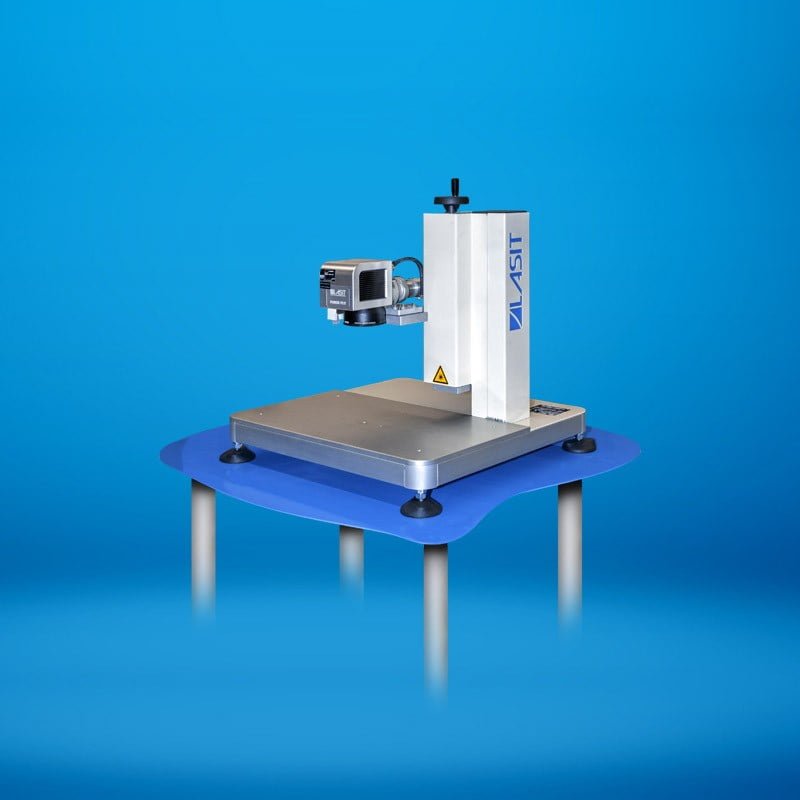

NOVOTEST TS-BRV Analog Brinell, Rockwell, Vickers Hardness Tester

This bench hardness tester is designed for hardness testing under Brinell, Rockwell, and Vickers method in line with ISO 6508, ASTM E10, ASTM E92, and ASTM E18.

The device is suitable for testing parts made of ferrous metals (steel, cast iron, mild steel and hardened steel) and nonferrous metals (aluminum and copper alloys). It is also suitable for hardness testing of hard alloys, carburized and chemically treated layers. TB-BRV is easy to set and use, it has a durable build and gives highly repeatable measurements.

This hardness tester can be a great helper anywhere when many hardness test methods need to be used, be it a manufacturing facility, research institute, metrology, laboratory, or a workshop.

Benefits

- Easy operation and simple build brings comfort of use

- The presence of a wide variety of scales make the device applicable to a wide range of materials – from very soft to the hardened

- The special movable table allows measuring imprints without removal of the test object

- The built-in high-precision microscope with the internal and external backlight makes the analysis of imprints easy and comfortable

- 3-in-1 solution for hardness testing by 3 different methods – Rockwell, Brinell, and Vickers

- Special stand for the microscope, which significantly simplifies operating the device

- An electric actuator – the main test load is completely automated

- Allows user to maximize the efficiency of the using portable hardness testers. Using this device user can verify standard hardness test blocks and calibrate portable hardness testers according to any of the most popular hardness scales.

Download the brochure