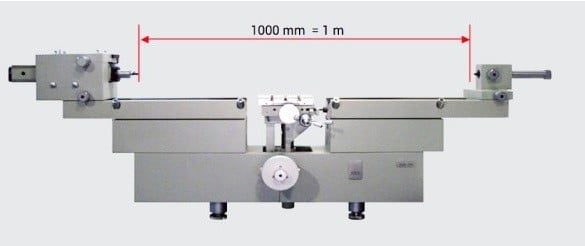

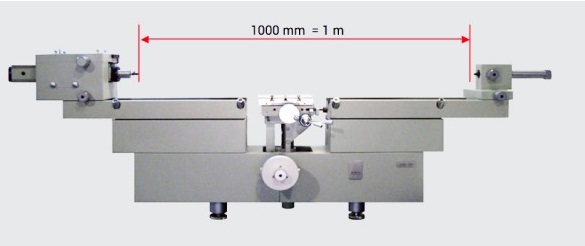

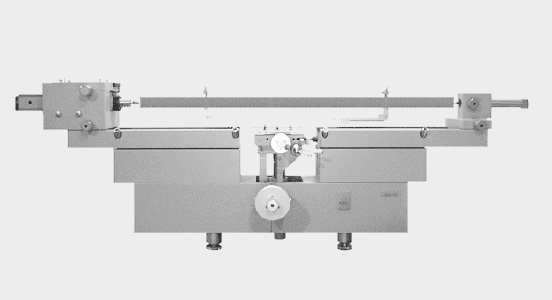

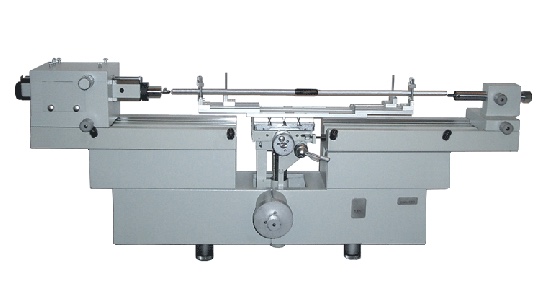

Universal Length Measuring System - Microrep DMS1000

Standard equipment:

|

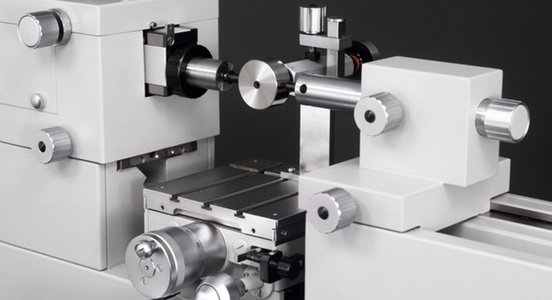

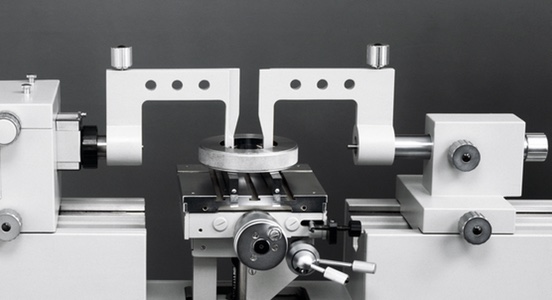

Plain Plug gage MeasurementThe movements of the work table allows high speed location of the inversion point. |

|

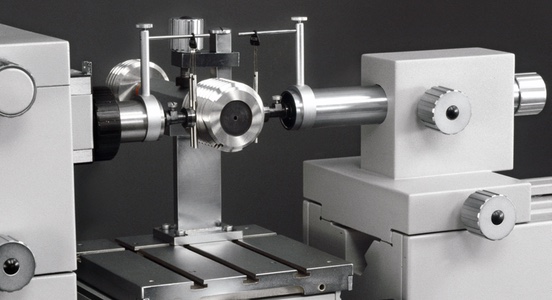

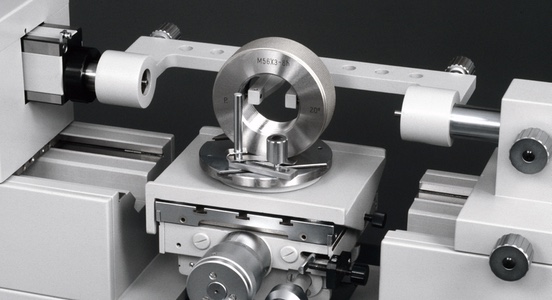

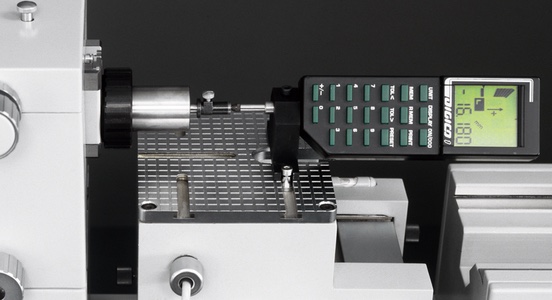

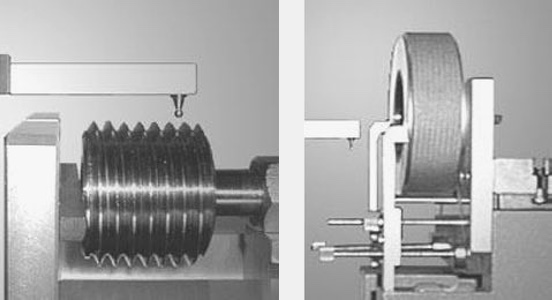

Thread Plug gage MeasurementThree wire method. Calibrated wires are part of the standard equipment included with the machine. |

|

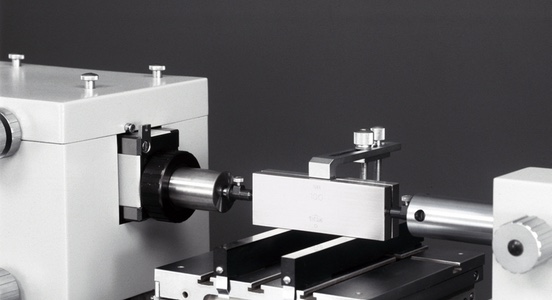

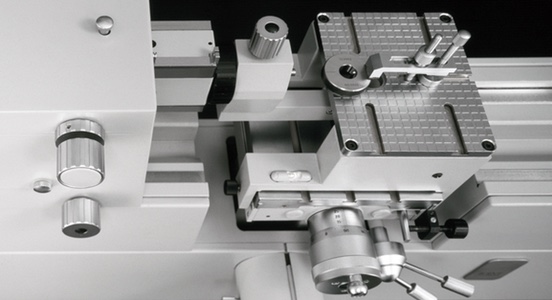

Workshop Gage Block InspectionThe inspection is carried out by comparison with master gage block. |

|

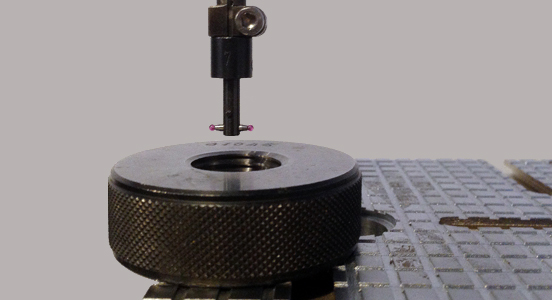

Plain Ring gage MeasurementPlain ring inspection is easy and accurate. |

|

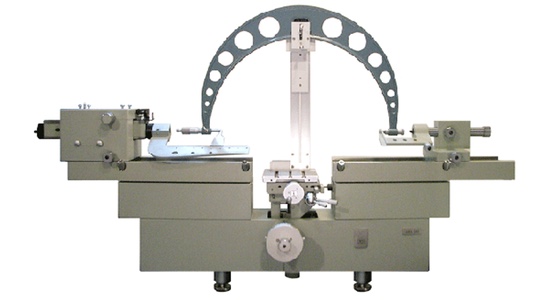

Thread Ring gage MeasurementThe standard device includes 12 pairs of spheres for internal thread measurement. Range: 14-90 mm |

|

Small Ring measurement deviceThe measurement is carried out with zero contact force. |

|

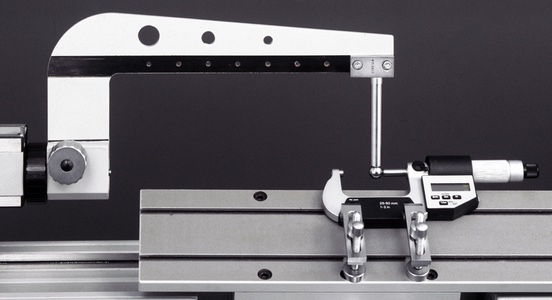

Snap gage measurementSnap gages are placed on a special holder. |

|

External Micrometer inspectionMicrometer head verification. |

|

Dial Indicator inspectionInspection of digital comparator, dial indicator and lever type probe. |

Temperature Compensation

Standard included. The temperature compensation device allows:

- direct compensation of the environmental temperature

- high thermal stability

- high accuracy in critical temperature conditions up to 28°C | 82°F

- direct reading of the temperature on the PC screen

Optional:

|

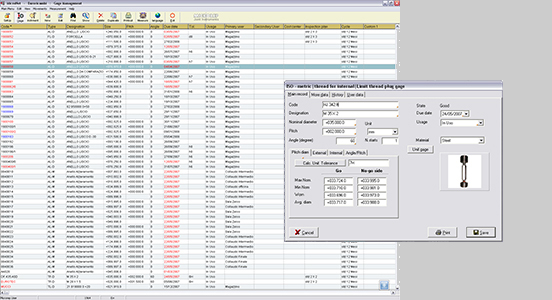

MicroNet – Gage ManagementSoftware standard included with the machine. MicroNet software allows to store gages into the database, automatic tolerance calculation, etc.. |

|

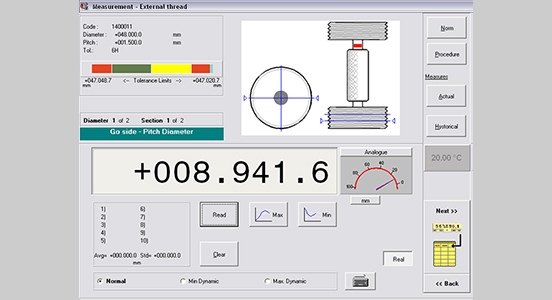

MicroNet – Gage MeasurementSoftware standard included with the machine. MicroNet software provides real time reading, thread formulae, automatic certificate printout, etc.. |

Small Plain Ring electronic deviceAn electronic lever probe device with spherical-end stylus, allows fast measurement of small plain ring gages. Note: the standard machine includes a manual system (small ring device) to measure small plain ring gage. |

|

Big Thread Ring deviceTo extend measurement range of thread ring gages up to 400 mm |

|

|

Long Gage Blocks calibrationA special table holds the gage blocks on the Airy’s points. |

|

Large Micrometers inspection |

|

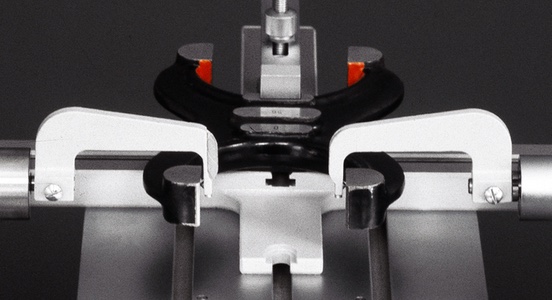

Calibration of RodsA special “V” table holds the gage |

|

T-sphere (small thread ring) deviceThe device allows to measure thread ring down to 3 mm | 0.12″. Working field: 3-90 mm | 0.12″-3.5″. Note: smaller spheres available on request |

|

Pitch measurement deviceInternal and External thread pitch verification. |

Range of applications (diameters from – to)

| external plain | 0 – 1000 mm | 0 – 40 “ |

|---|---|---|

| internal plain | 0 – 480 mm | 0.04 – 19 “ |

| external thread | 0 – 480 mm | 0 – 19 “ |

| internal thread | 3 – 400 mm | 0.12 – 16 “ |

Measuring range

| absolute | 100 mm | 4 “ |

|---|---|---|

| differential | 1000 mm | 40 “ |

Download the brochure