Vertical machining center RigiMill MT - Moving table

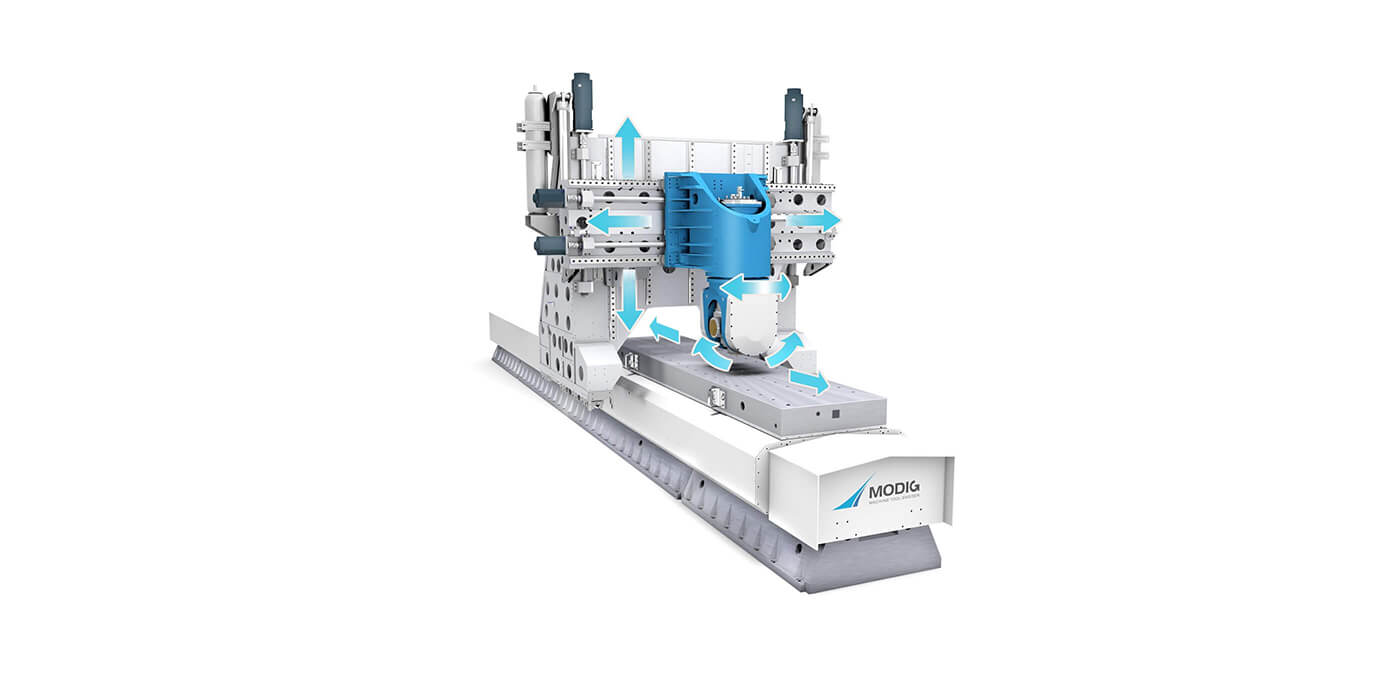

The RigiMill Moving Table (MT) is the fixed-gantry plus moving table design, with identical bridge structure as the RigiMill Moving Gantry (MG). RigiMill MT provides the highest quality in precision and rigidity, with chip removal rates up to 55 cubic inches/min (0.9 liter) in titanium and 1,000 cubic inches/min (16.4 liters) in aluminum.

RigiMill MT is equally as compact as the RigiMill MG but requires less floor space. Its working envelope is suitable for shorter parts, up to 240” (6,000 mm) long. When offered with Modig standard pallet system, it has an impressive minimum foot print within a fully automatic palletized cell.

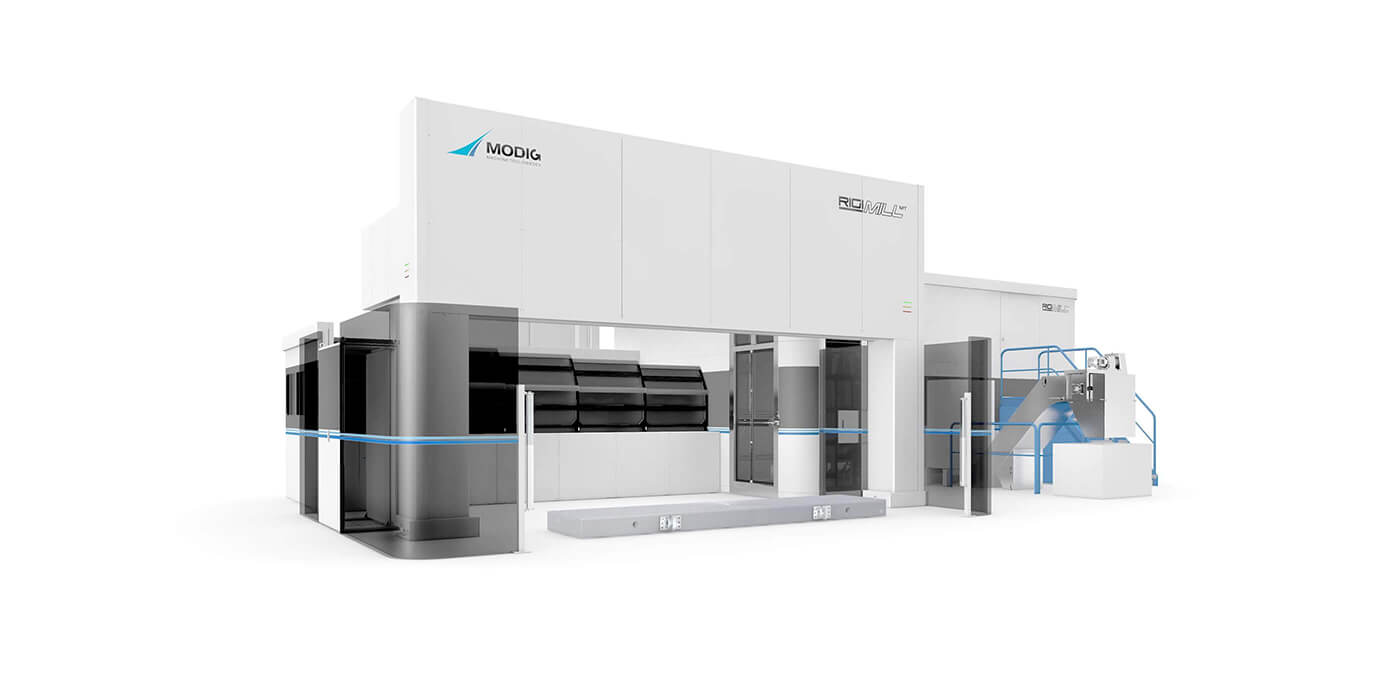

The RigiMill MT design includes a complete machine housing where the parts are processed into a fully covered working zone.

RigiMill MT is available in three sizes 80” (2,000 mm), 160” (4,000 mm) or 240” (6,000 mm).

SUCCESS STORY – MODIG AND ASCO INDUSTRIES

Asco Industries was looking for a precise finishing machine for titanium military airplane parts. The key characteristics were a robust and precise machine to ensure a good and stable quality output. From that viewpoint, MODIG provided a solution with the moving table gantry machine type.

The machine has proven to meet the required precision and is a good solution for the required capabilities, and we recently achieved 100% uptime with an average of 98%.