XT H 225 for all-purpose X-ray and CT inspection

XT H 225 for all-purpose X-ray and CT inspection

Detailed capture and measurement of internal component and assembly features is often vital for quality control, failure analysis and material research. The XT H 225 systems offer a microfocus X-ray source, a large inspection volume, high image resolution and is ready for ultrafast CT reconstruction. They cover a wide range of applications, including the inspection of plastic parts, small castings and complex mechanisms as well as researching materials and natural specimens.

Benefits

- Proprietary 225 kV microfocus X-ray source with 3 µm focal spot size

- Easy system operation and low cost-of-ownership

- Stunning images providing great insight

- High performance image acquisition and volume processing

- Straightforward inspection automation

- Safety first

Applications

- Fault detection and failure analysis

- Assembly inspection of complex mechanisms

- Dimensional measurement of internal components

- Part-to-CAD comparison

- Advanced material research

- Analysis of the biological structures

- Digital archiving of models

Benefits & features

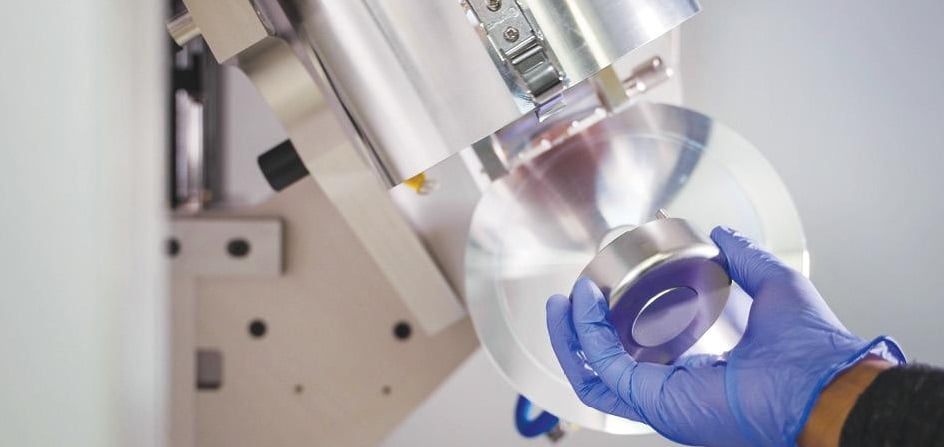

Superior accuracy and performance through proprietary 225 kV microfocus X-ray source

The default microfocus source is equipped with a reflection target, offering a 3 micron spot size. With the optional transmission target, you obtain an even smaller spot size and higher magnification capability. Regardless of the target of choice, the XT H 225 system uses an open-tube X-ray source that guarantees a lower cost-of-ownership

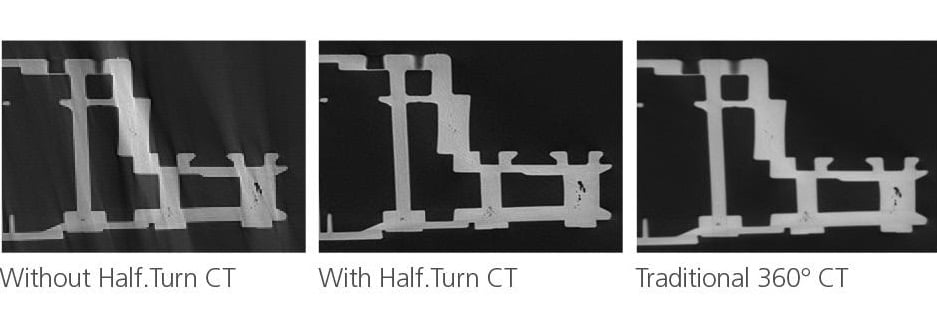

Stunning images from internal structures

A small spot size and a high-resolution flat panel create sharp images. Adapt resolution to your needs: full part in coarse resolution and high resolution in a desired region of interest.

High performance processing

The core of the processing power is situated in the XT software suite that builds on Nikon Metrology’s track record of improving sample throughput and simplifying operation to take the systems out of the hands of experts and into the hands of users. XT Software also brings the fastest reconstruction of CT data currently available on a single PC. This PC is built from standard components to aid serviceability. The sample throughput can be improved further by the use of additional PCs. The complete system is also ready for any market leading CT visualization and processing software, such as VolumeGraphics.

Easy operation and automation

Users are operational with the system within a few days of training. A CT wizard guides operators through the data acquisition process.

Customizable macros automate the measurement workflow, and tight integration with industry-standard post-processing applications streamline the decision making process.

Safety first

Full protective enclosure – compliant to CE and DIN 54113 radiation safety standards – requires no special badges or protective clothing. Continuous fail-to-safe monitoring during system operation. Radiation shielding is to better than 1µSv/hour external, and dual fail-safe switches/relays ensure safe operation

Low cost of ownership

The open X-ray tube allows for local maintenance of internal tube components. The 3-wheel transportation incorporated to easily maneuver through double-door entries. Also no special floor treatment is to install XT H 225.

Configure the system to your specific needs

Specific applications require more detailed images or higher accuracy. XT H 225 can be configured with different flat panels (Varian, Perkin Elmer) or source configuration (reflection/ transmission target) to make the system ideally suited for your needs.

XT H 225ST system is an extended version to hold larger samples up to 50 kg with a diameter of about 50 cm.

Download the brochure