Marcare si gravare laser pe materiale plastice

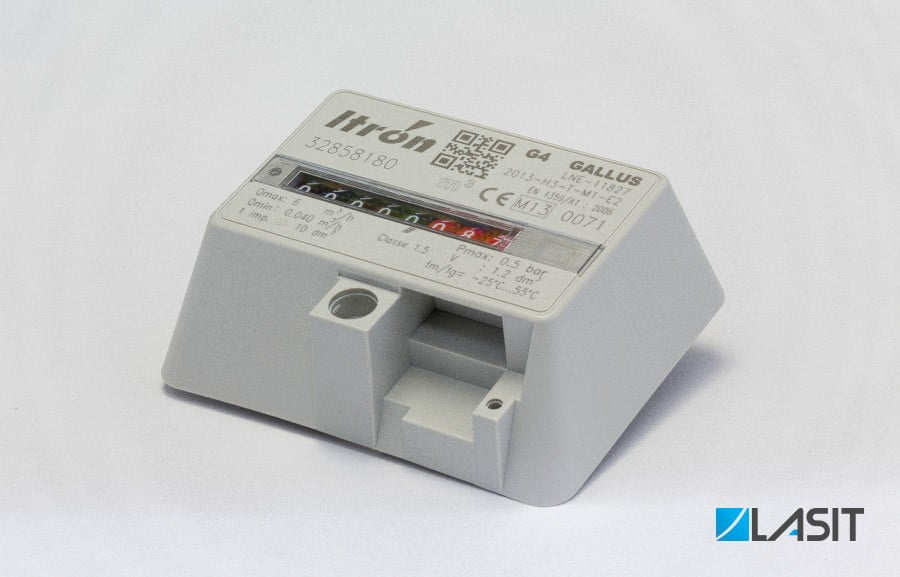

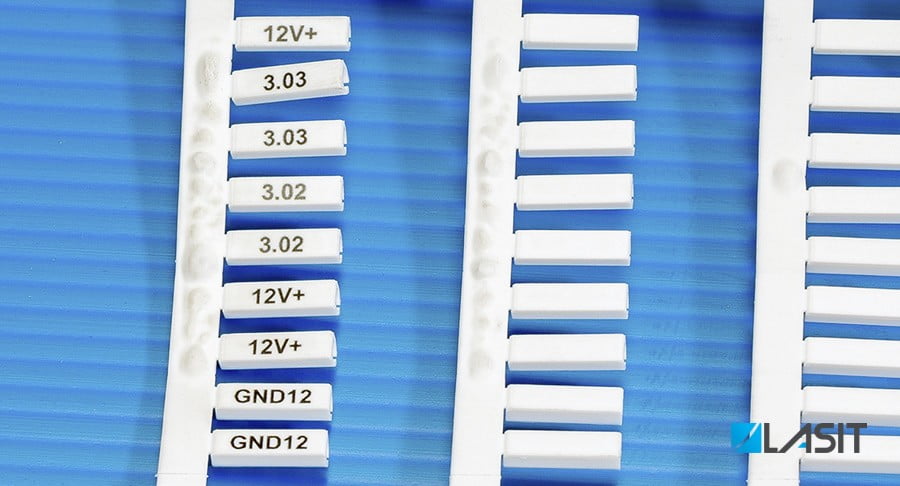

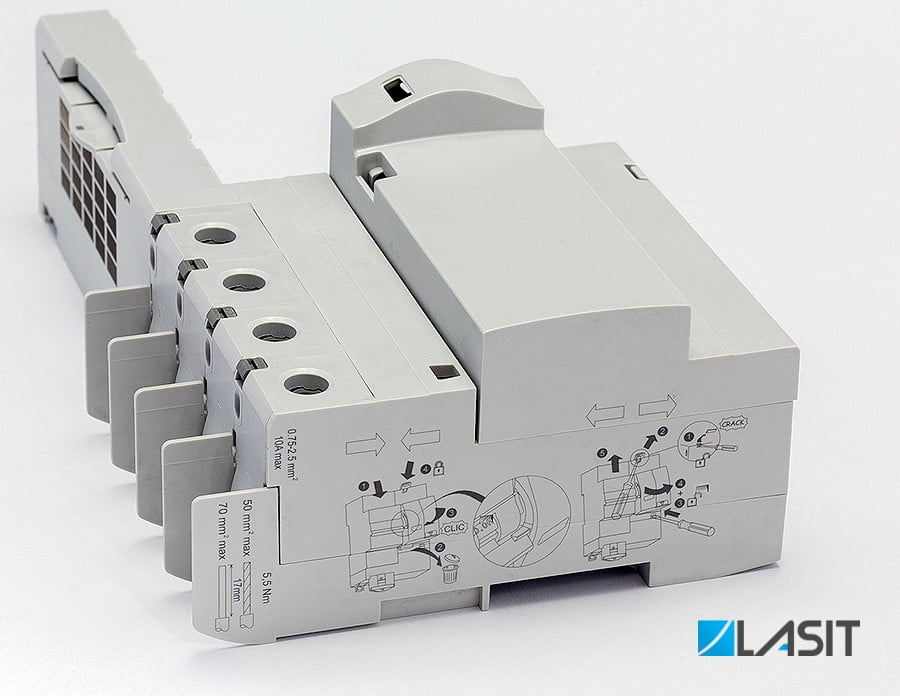

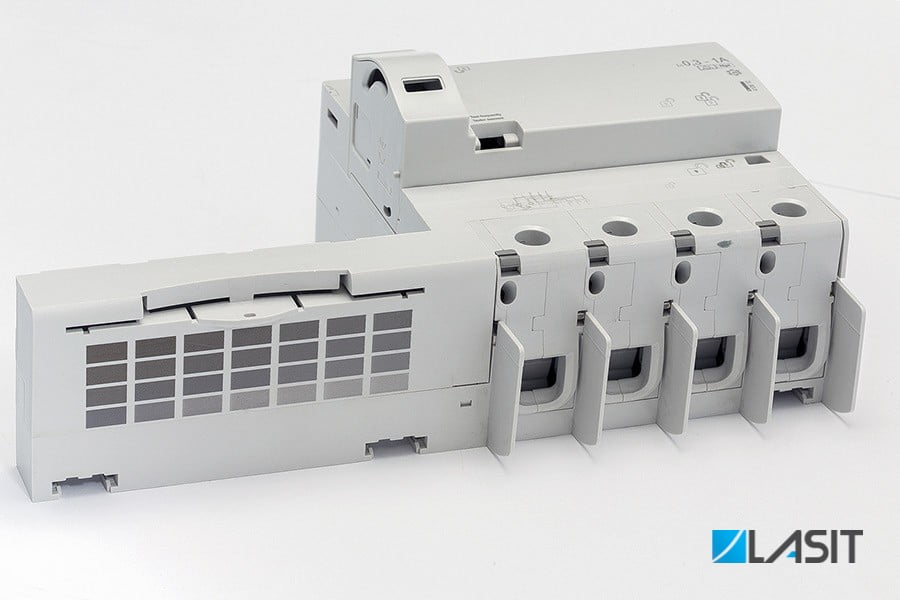

It is impossible to make a general statement about the process of marking plastic materials, and this has to do with technical – mainly chemical – reasons. Aside from the base materials, the colors (pigments) and other additives (fillers, generic additives, and flame-retardant agents) play an important role in selecting the best laser for your needs. Here you can see a selection of plastic pieces that have been marked using LASIT’s laser engraving machines.

What are the main advantages of laser marking and engraving plastic?

Many commercially used plastics can be marked and engraved with several different laser wavelengths and methods, depending on the type of plastic. The main advantages of laser marking and engraving plastic are as follows: in machining, there is no tool wear or vibration as it is a noncontact process; there is low heat input, which results in less distortion. Moreover, laser marking on plastics is an extremely quick and versatile process which gives permanent marks.

Why laser marking on plastic is better than the other marking technologies?

Laser technology has slowly replaced outdated ink marking technologies over the years, mostly as far as plastic materials are concerned. Today’s laser-markable plastics offer high contrast and, in many cases, a contrasting color rather than just black or white, which is essential in product traceability when it comes to imprinting greater amounts of data on ever-smaller plastic parts. Environmental issues are another driving force. Laser marking on plastic uses no inks or solvents, nor does it require the energy-intensive drying steps typical of ink-marking technologies.

Can any type of plastic material be laser processed?

Technically no. It is impossible to make a general statement about the process of laser engraving or marking plastic materials because of chemical reasons. This is the reason why LASIT offers a sample service in order to help the customer to choose the best laser solution depending on the particular type of plastic to be marked. We have provided the sampling room – only to realize tests – with a wide range of laser sources (fiber laser, UV laser, green light fiber, green light diode, CO2) for all customers needs.

Which is the best laser source to laser mark and engrave plastics?

The best laser source to laser mark and engrave plastics is the green laser. LASIT manufactures FlyAir Green which is a solid state laser (active material YVO4), with a pumping axial and duplication crystal of the laser beam inside the cavity, and also FiberFly Green which uses the same innovative technology of the FiberFly system (active fiber doped with Ytterbium) with the integration of a duplication crystal wavelength. These laser sources are ideal for marking opaque, translucent and transparent plastic materials.