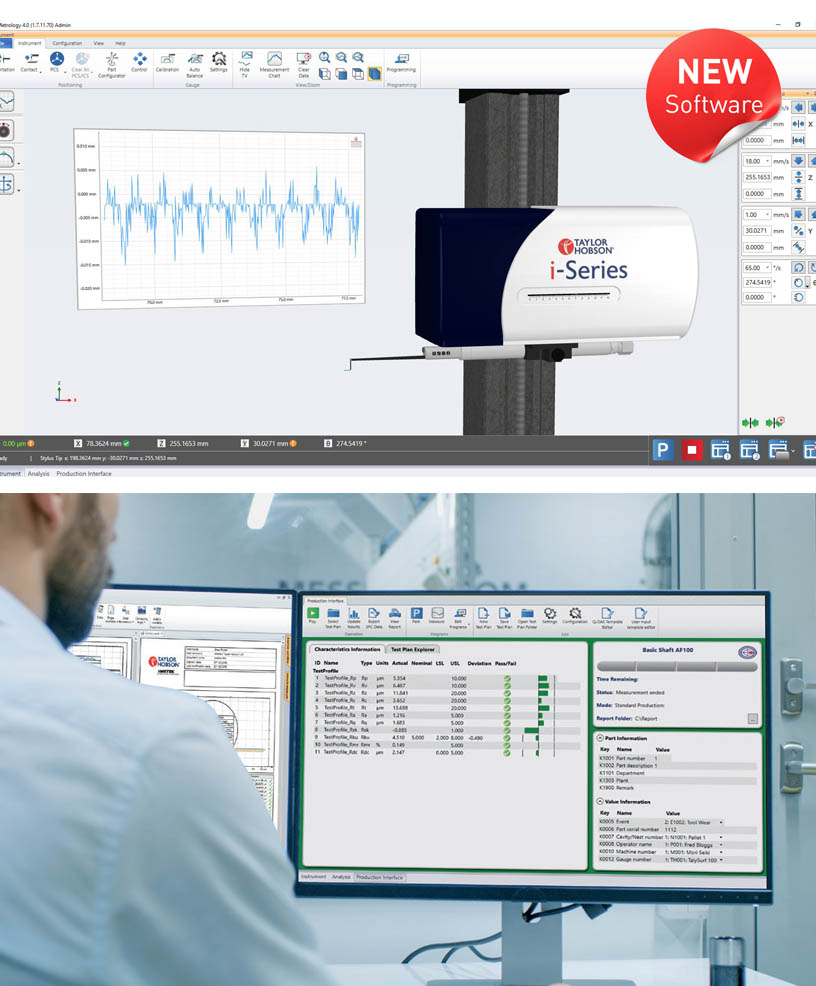

Sistem pentru rugozitate, liniaritate şi contur - Form Talysurf i-Series

A high range high resolution system for contour and surface finish measurement

Ideally suited for automotive, bearings, gears and many other applications

Surface and Contour in One

The Form Talysurf i-Series is a high accuracy instrument range capable of simultaneous surface finish and contour measurement. The system’s low noise axes and high resolution gauge ensures measurement integrity with choice of gauge ranges providing versatility for a variety of applications.

Tailored to suit your application

From screw threads to crankshafts or engine block to valve guides select the configuration that suits your requirements. Available in 1 mm, 2 mm and 5 mm gauge range with a traverse length of up to 200 mm.

Temperature compensation

Standard across all i-Series models, this unique system monitors and feeds back changes in ambient temperature, ensuring consistent system performance and high measurement integrity, regardless of environmental effects.

Reproducible measurement results

Decades of experience, ultra precision machining expertise and FEA optimized design combine to provide low noise and near flawless mechanical execution of the measuring axes. Further enhancement via the use of traceable standards and exclusive algorithms effectively eliminates instrument influence from the measurement results.

Unparalleled measurement capability

Surface detail – High resolution gauges with low noise enables roughness, waviness and form in one measurement.

Contour – Our patented calibration technique enables measurement of radii, angle, height, length, distance and more.

3D – Using an optional motorized Y-stage and Talymap, transform your conventional 2D measurement in to a 3D analysis tool.

Applications include:

Cylinder heads – Valve surface finish – Valve angle

Roller bearings – Surface finish – Form error and DXF comparison

Gears – Surface finish – Root radius and form deviation

Crankshafts – Surface finish – Fillet radi and DXF comparison

Ball screw – Pitch, angle, form and Linear dimensions

Q-Link SPC Software interface

Q-link is a new production and advanced SPC software interface offering simplicity, versatility and traceability. Q-link provides direct communication with Q-Das SPC software which delivers feedback to your manufacturing process.