Automated Computed Tomography - Semi-automated CT Inspection

Semi-automated CT inspection

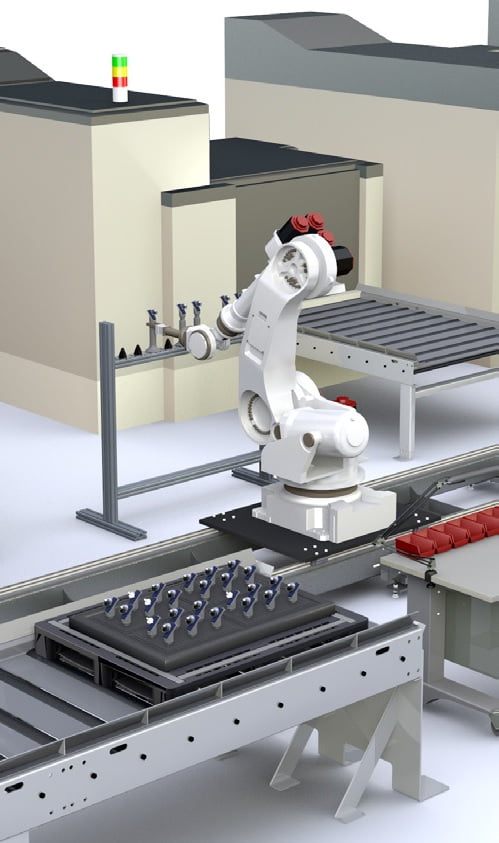

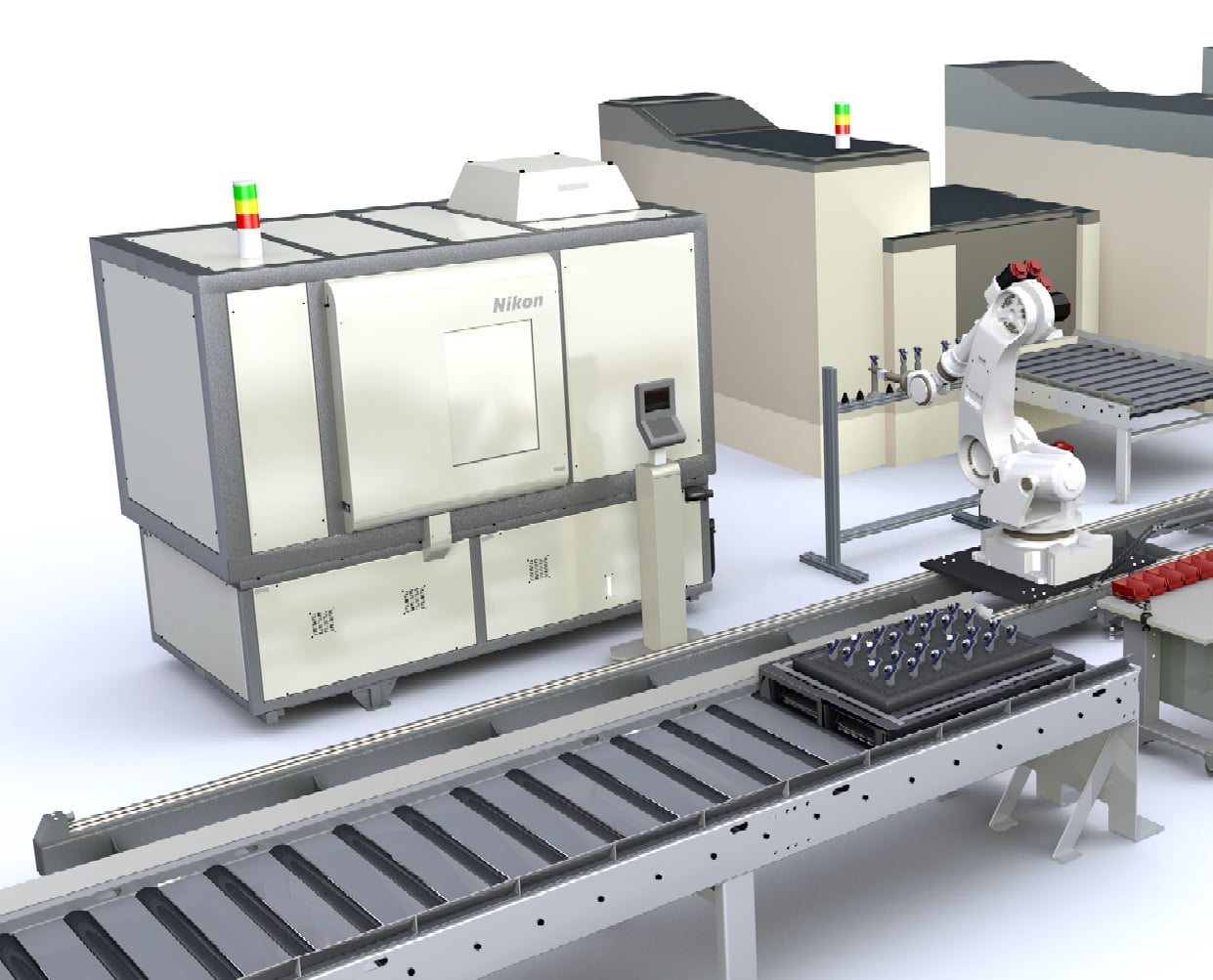

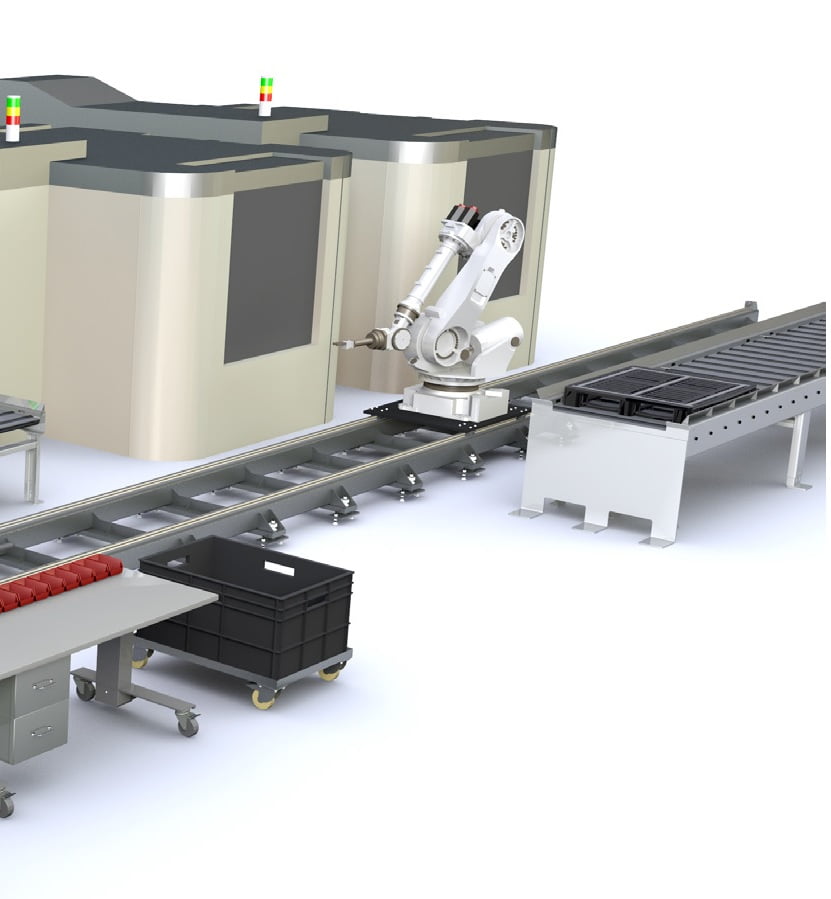

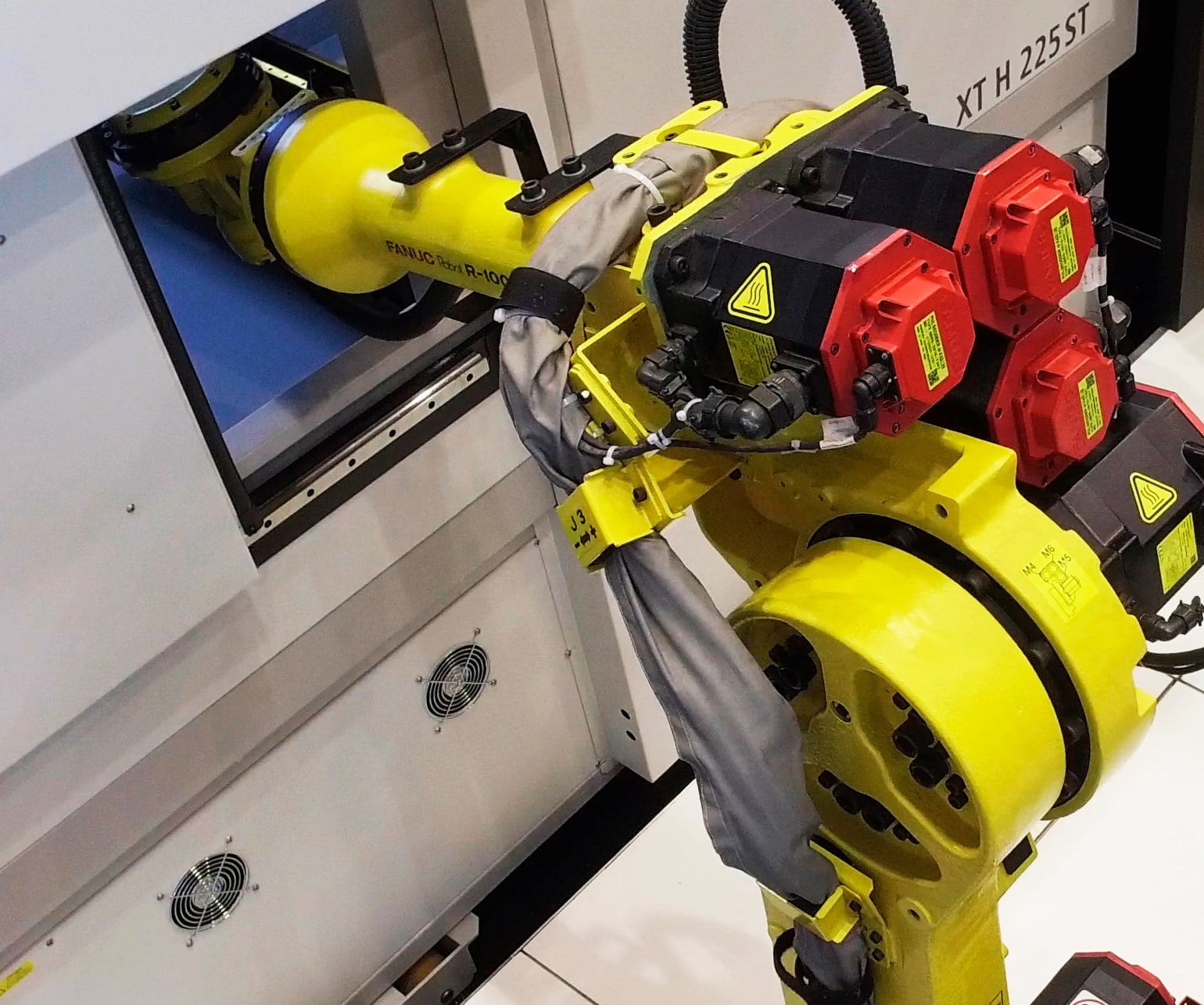

In a production environment where fast inspection tact-time is required, semi-automated CT inspection systems almost replace all manual tasks involved with CT inspection. Individual parts are manually loaded onto the sample holder. Or more advanced, the operator loads a fixture with multiple samples, that are each positioned onto the sample holder by an internal loading system.

By communicating with production databases the CT system can automatically recognise the part to be inspected, and adjust all parameters accordingly, further removing possible operator error. Inspection results can be written back to the database for further analysis or to preserve data history.

Benefits

- Custom, simplified user interface (UI) guides the user through the complete process

- Basic operator skills needed

- Part identification by bar or QR code reader

- Integrated with manufacturing database

- Repeatable process

- Process control (SPC)

Download the brochure