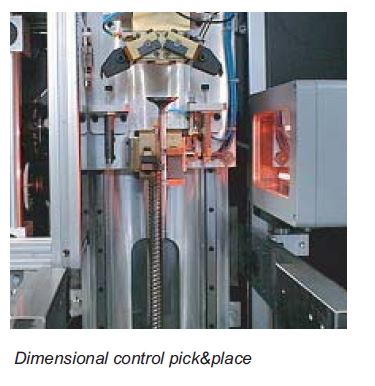

Pick and place system for the dimensional control for automotive valves with a rate of 600 valves/hour. The machine allows the valves metrological inspection by means of a vision system based on two lenses that detect measurements of the piece. The application can be integrated in production line with automatic loading and unloading of the piece to be measured. The equipment guarantees extreme accuracy (+/- 1,5 micron) and repeatability of measurement

detected in a very limited cycle time and taking measurements of length, width, distance, diameter, bend radius and angles.

A compact, quick and cheap solution that allows the control of 100% of production.

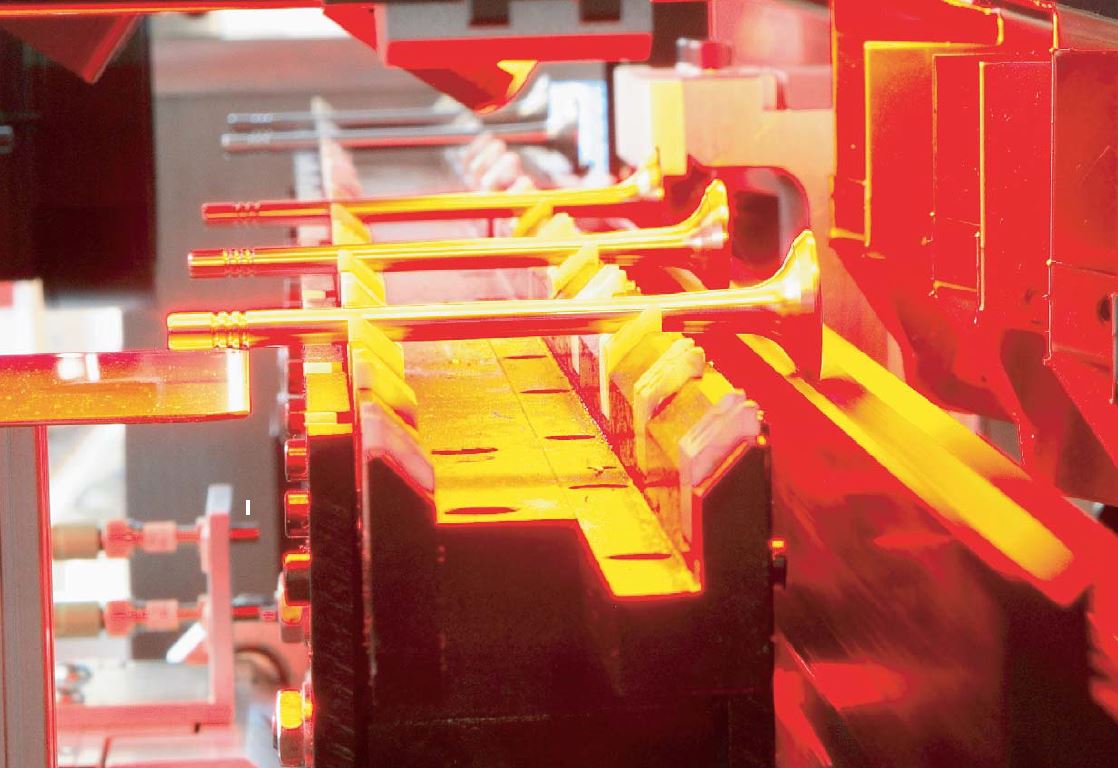

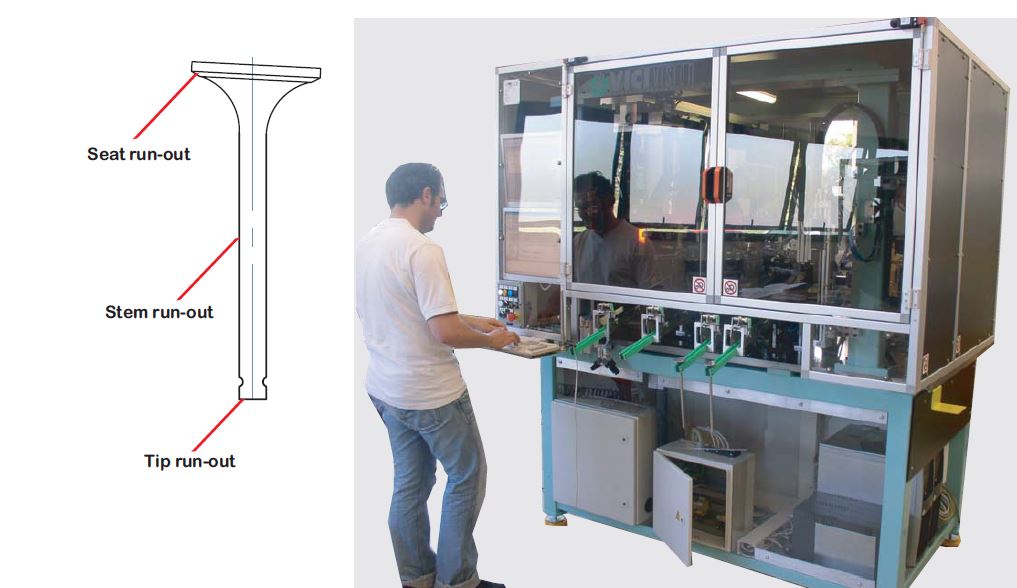

RUN-OUT control quick and versatile.

The system allows to execute the control of all the dimensional parameters of the valves from static measurements such as lengths, diameters and radius, to run-out measurements with valve in rotation.

Valves are picked up from transport line one by one, by a manipulator and subjected to various checks:

- external dimensional control

- seat run-out control

- stem bow control

- tip-end run-out control

An independent reject station is arranged for each valve’s feature checked.

The equipment is available in 2 versions with or without static dimensional control.

VRO is a solution able to process up to 600 valves/hour with extremely reduced retooling times with type changing, ideal to process batches of small dimensions such as lorry valves.