Machine tool calibration - Ballbar API

Increase Manufacturing Efficiency

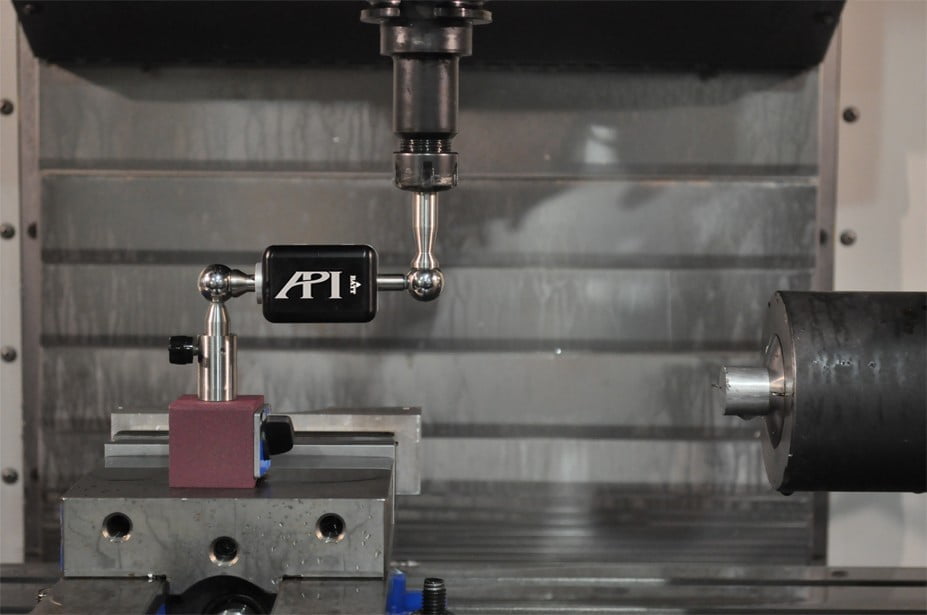

The telescoping Ballbar from Automated Precision Inc. (API) quickly and easily checks contouring accuracy by testing how machine axes move in a circular path. API’s Ballbar measures the deviation made by the machine tool and displays the data in a polar plot format. This one affordable piece of equipment can save a machine shop thousands in machine tool servo maintenance and downtime.

Where Ease Meets Precision

Straightforward operation and automatic error identification combine with our unique parallel spring suspension that provides extremely accurate and frictionless measurement. For large machine tools, the Ballbar offers extensions up to 1.5 meters in radius. This system is the perfect solution for machine tool quality maintenance.

Error Parameters Measured:

- Backlash

- Squareness

- Stick-slip

- Servo lag

- Straightness

- Scale mismatch

- Machine and servo vibration

To help completely calibrate your machine, look at the XD Laser, Swivelcheck, and Spindle Analyzer.

Download the brochure