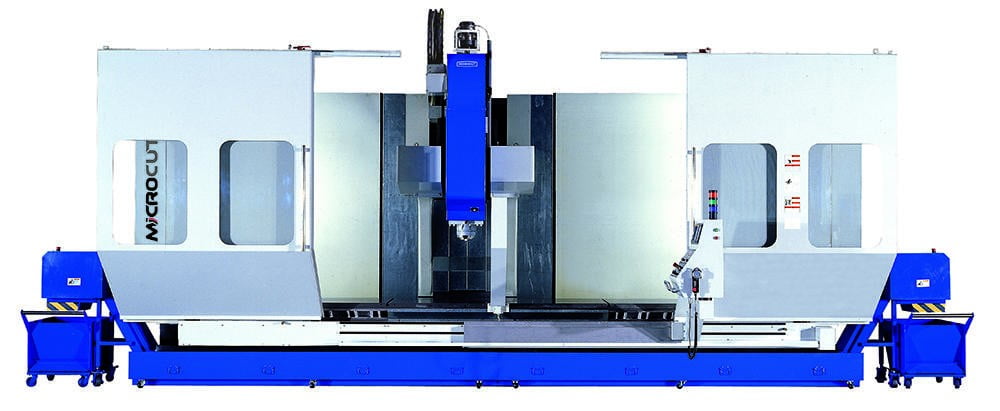

Travelling column machining centers - Microcut Seria TC

The vertical machining center, TC series is characterized by high-speed and superior precision machining. With the design of powerful drivers, moving column and rigid construction, the model is suitable for heavy cuttings with perfect surface roughness. The superior tooling system design features 300mm tool length availability, easy tool loading, servo driver for fast and accuracy tool selection, and extremely large loading capacity. Besides, the TC series is equipped well protected guarding for safety.

Specification:

| ITEM | UNIT | Travelling Column Machining Centers | ||

| Modle | TC-1850 | TC-2100 | TC-3200 | |

| Table size | mm | 2800×700 | 2800×700 | 3500×850 |

| Max. table load | kg | 4000 | 4000 | 6000 |

| X axis travel | mm | 1850 | 2100 | 3200 |

| Y axis travel | mm | 850 | 610 | |

| Z axis travel | mm | 850 | 610 | |

| Spindle taper | ISO | ISO 40 | ISO 40 | ISO 40 |

| Spindle speed | rpm | 10000 (ISO 40) 6000 (ISO 50) |

10000 | 10000 (ISO 40) 6000 (ISO 50) |

| Main motor (conti./30min.) – Fanuc | kW | 22/30 (BT50) 15/18.5(BT40) |

15 / 18.5 | 22/30 (BT50) 15/18.5(BT40) |

| X/Y/Z Rapid feed | m/min | 30/30/30 | 40/40/40 | 30/30/30 |

| Transmission | direct | belt | direct | |

| Guideway type | Linear guideway | |||

| ATC | Tool | #40: 48 #50: 32 |

#40: 48T | #40-48T #50-32T |

| Machine weight | kg |

23000

|

23000 | 30000 |

Standard accessories:

|

|

|

|

|

|

|

Optional accessories:

|

|

|

|

|

|

|