Horizontal Machining Center TDZ Power - 5 axis – TDZ HCB 110/GD CNC

Horizontal Machining Center TDZ Power – 5 axis –– TDZ HCB 110/GD CNC

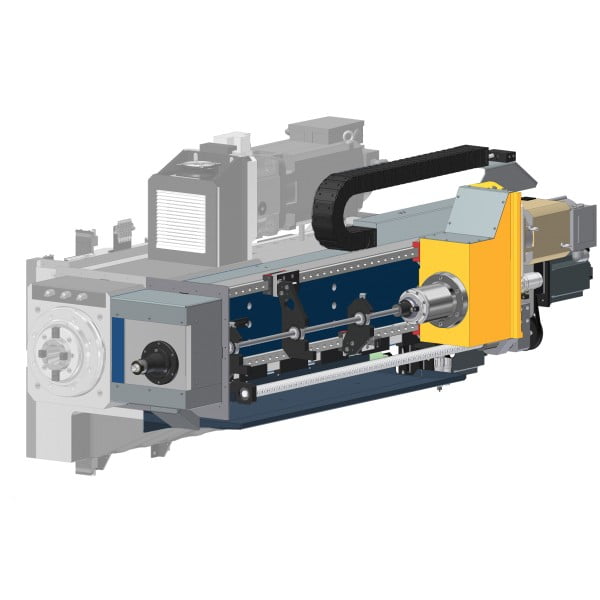

HCB 110 CNC / GD is a universal machine that combines horizontal boring machine and deep hole drilling machine. The base is horizontal boring machine HCB 110 CNC supplemented with additional equipment for deep hole drilling. Optionally the machine can be also fitted with additional vertical table for 5 axes positioning. Headstock H110 is used for rough and finish machining, pocket milling, countersink and other common technological operations. Device GD 1300 is used for additional deep hole drilling of holes with diameter from 3 to 25 mm and depth of up to 1300 mm. Using H110 and GD1300 on one machine improve production effectiveness, because there is no need to move the workpiece from the boring/milling machine to other special machine for deep hole drilling. After adding of vertical table we get ideal machine for machining of injection molds. With the combination of HCB 110 CNC, deep hole drilling equipment GD 1300 and additional vertical table we can machining injection molds with the 60% savings of secondary times and up to 30% savings of machining times.