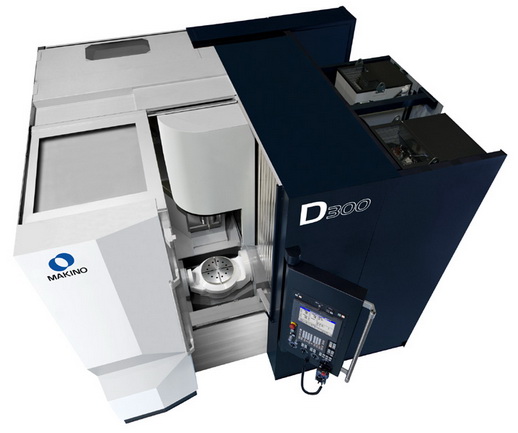

Vertical Machining Center Makino D300

D300 speed and flexibility for complex aerospace machining

The D300 is the newest addition to Makino’s family of 5-axis vertical machining centers for the aerospace market. Similar to the D500, this 5-axis vertical machining center is designed to reduce setups and improve accuracy in the toughest small aerospace machining applications, such as titanium blisks and propellers.

The D300 table offers a work-area diameter of 300mm, accommodating workpiece sizes up to 450mm by 270mm and 120kg. The machine provides X-, Y- and Z-axis travels of 300mm, 500mm and 350mm, respectively, at feed rates of up to 60,000mm per minute. Rotary table axes offer rotational motion of 240 degrees(±120 degrees) on the A-axis and a full 360-degree (continuous rotation) on the C-axis.

Enhanced cutting capability and positioning speed

The D300 is standardly equipped with a 15,000-rpm HSK-A63 spindle with 120Nm (42Nm continuous) of torque for flexible, high-speed machining of various workpiece materials including steel, aluminum and titanium. Other optional spindle configurations include a 20,000-rpm HSK-A63 spindle and 30,000-rpm HSK-F63 spindle.

The direct-drive motor design of the D300’s C-axis rotary table and A-axis trunnion eliminates twist and torsion for outstanding positioning accuracy and repeatability. Its ultra-high-torque motors also provide superior acceleration and rotary speed characteristics that can reduce cycle times of complex 5-axis simultaneous machining applications by up to 60 percent.

The D300 axis configuration is unique, delivering added precision performance. The length of the trunnion assembly runs parallel to the X-axis motion only, making the trunnion assembly deflection-free during quick axis motion for greater accuracy than traditional 5-axis configurations.

The D300 features roller linear guides across all linear axes for extra rigidity and stiffness while maintaining very productive rapid and feed rates. Its Y- and Z-axes are located above the work zone, with the X-axis located under the table to ensure a cantilever-free design and highest positioning accuracies.

Professional 5 CNC control improves performance and operability

The D300 uses the Makino Professional 5 Control, which provides a Windows CE graphical user interface (GUI) with touch-screen access, and the networking and storage capabilities of a data center. This data center features a flexible, user-friendly program and data management for quick, seamless changes from one setup to the next. Its built-in Ethernet networking capability offers ready integration to off-machine program storage.

Also featured in the D300 is Makino’s proprietary, next-generation Super Geometric Intelligence (SGI.4) software developed specifically for high-feed rate, tight-tolerance machining of complex, 3-D contoured shapes involving continuous tiny blocks of NC data that ensures production rates faster than standard CNC systems while maintaining high accuracy. SGI.4 helps deliver the lowest cycle times and costs achievable by reducing machining cycle times on dies, complex cavities, and cores and medical parts by as much as 40 percent when compared to most other control technologies.

The D300 incorporates control enhancements to improve 5-axis machining performance and operability. The tool center point (TCP) control allows programming based on the tool tip so that tool-compensation features can be applied. Further TCP developments also improve the cutter path to achieve greater surface quality. Dedicated user-friendly screens simplify the overall application of 5-axis machining, and easy-to-apply functions prevent interference between the spindle and trunnion during automatic operation to improve risk-free production.