Vertical Machining Center Makino V99

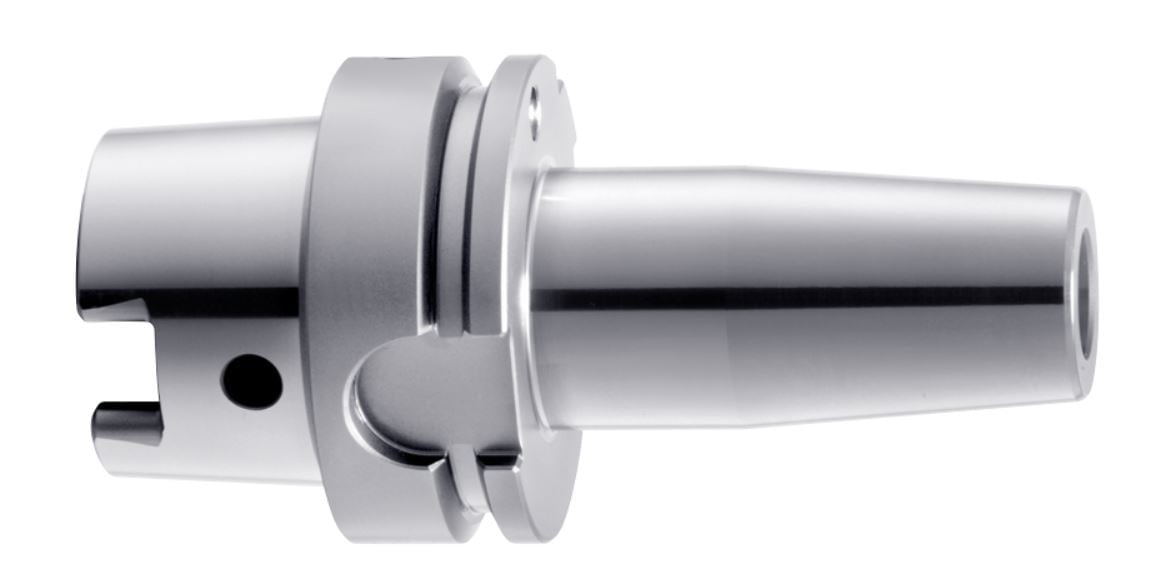

The V99 vertical machining center has been specifically designed to minimize thermal distortion for part precision and enhance higher quality finishes on die/mold output. The V99 provides environmentally-controlled machine accuracy enhancements, such as Makinos patented core cooled, under-race lubrication system which minimizes spindle distortion and twin shield-style splash guards to reduce the effect of temperature change in the factory. Available with either a HSK-A63 – 20,000 RPM or a HSK-A100 – 12,000 / 18,000 RPM spindle, the V99 can rough and finish hardened steel cavities/cores far more efficiently than general purpose machines. Rigid linear guides and twin ball screws are adopted for the Y-axis for a work piece up to 4.0 ton.