4- axis. Two spindles. 2 or 3 rotary tables. Bar or Extrusion machining. High production capabilities. Complete parts in one setup.

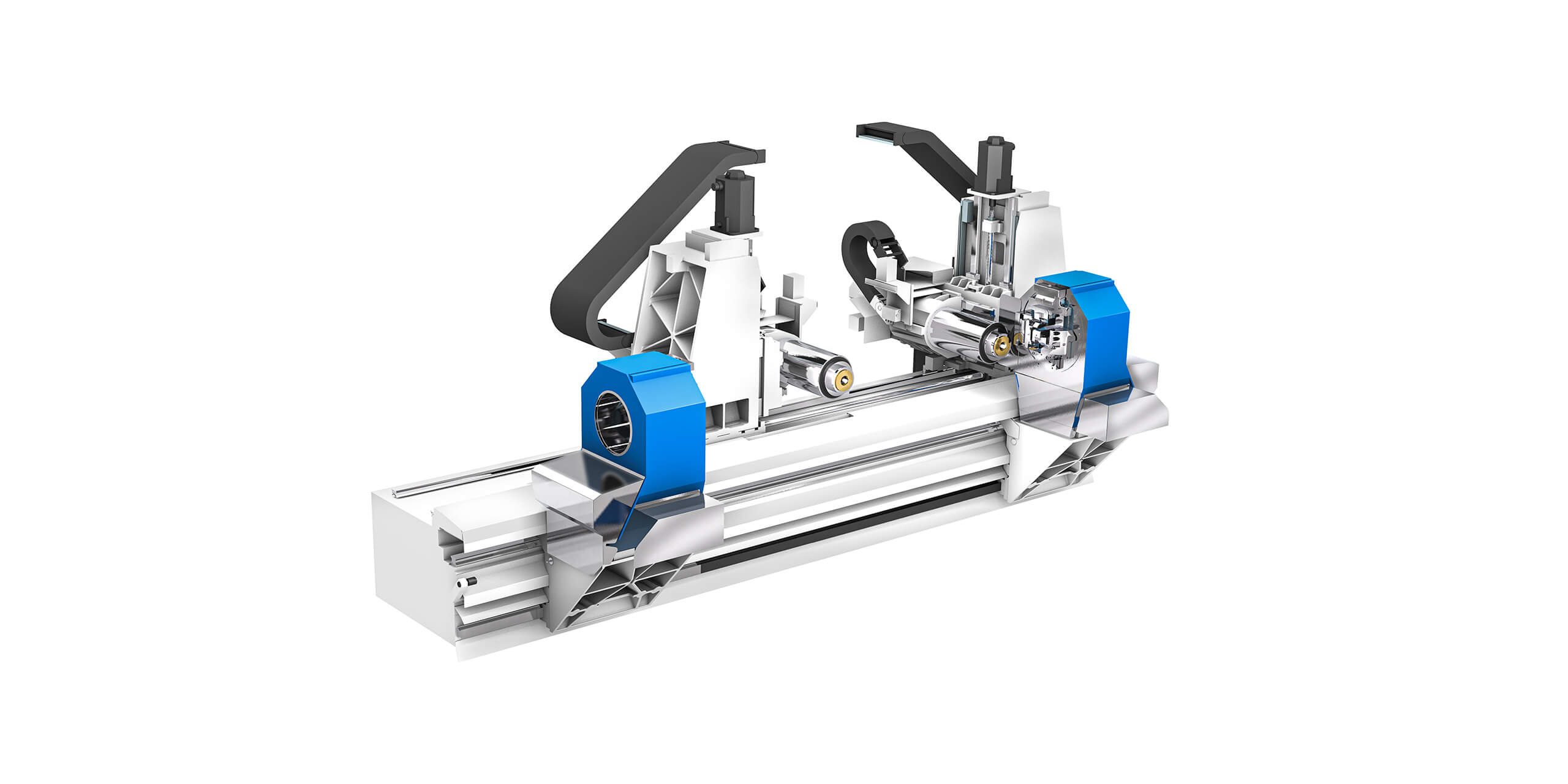

The HHV DUO is equipped with two spindles for the increased need for a higher output in the automotive industry. A 2 x 4-axis horizontal machining center with two or three rotary tables with options for larger rotary tables for bigger and heavier extrusions. The HHV DUO provides outstanding production rate capabilities and completed parts in one setup.

PRODUCT INFORMATION

Our advanced and innovative machine tool portfolio can tackle any automotive part machining, regardless of design and complexity. The new HHV DUO is equipped with two spindles for the increased need for a higher output in for example the automotive industry, the throughput is between 1,5-1,7 times faster than with the single machine.The HHV DUO is a 2 x 4-axis horizontal machining center with two or three rotary tables with options for larger rotary tables for bigger and heavier extrusions. With 30,000 rpm spindle speed in each spindle and 2,400”/min (60 m/min) feed rates in X/Y/Z/U, the HHV DUO provides outstanding production rate capabilities and completed parts in one setup;

- 2 x 4-axis horizontal machining center

- 2 or 3 rotary tables with options for larger rotary tables

- Throughput is between 1,5-1,7 times faster than the single spindle HHV

- Complete parts in one setup

- Low cost fixturing

- Guaranteed 40-70% cycle time reduction

2-AXIS SAW – NEW OPTION AVAILABLE FOR END-WORK

A new option for the HHV series is also a 2-axis saw for end-work. A saw can be mounted on one of the rotary tables operated with one or two axes from the main CNC control. With a rotating axis on the saw there is a possibility to cut compound angles by using the rotation of the rotary axis in combination.

The MODIG Technology provide machining solutions to a substantial production with cost savings and consistent part accuracy.