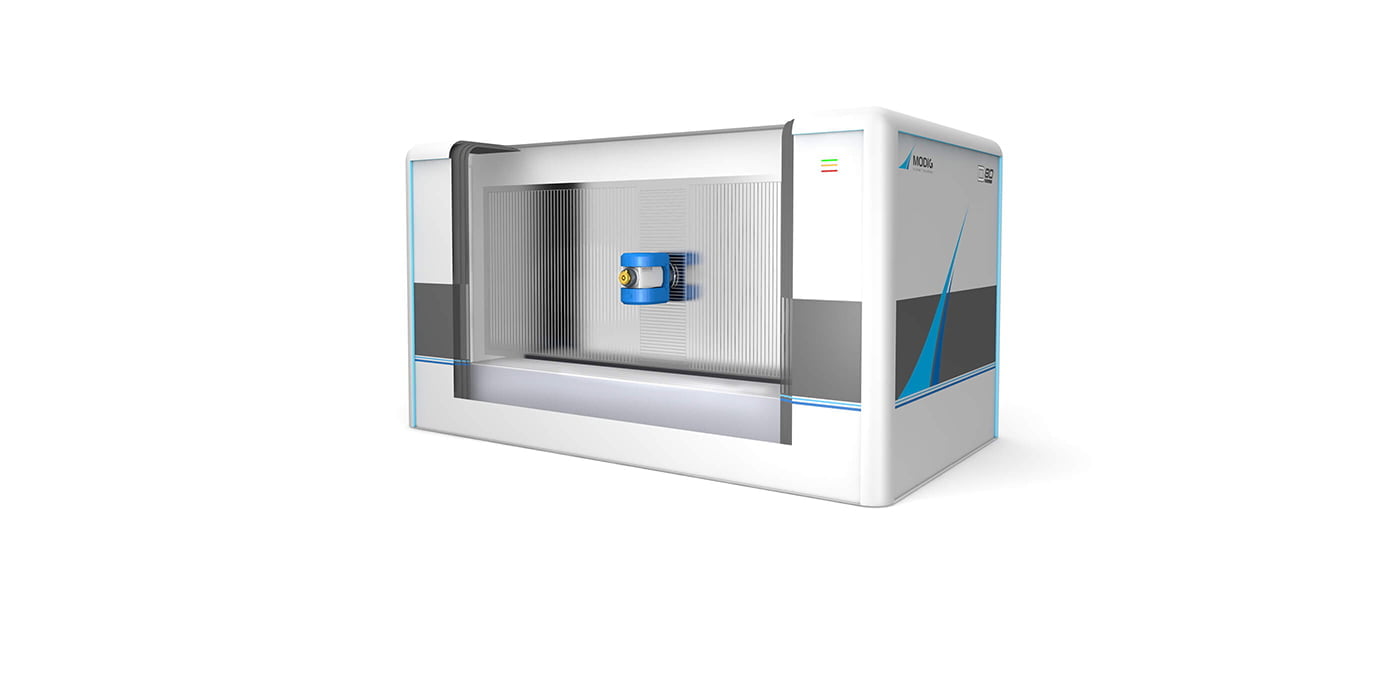

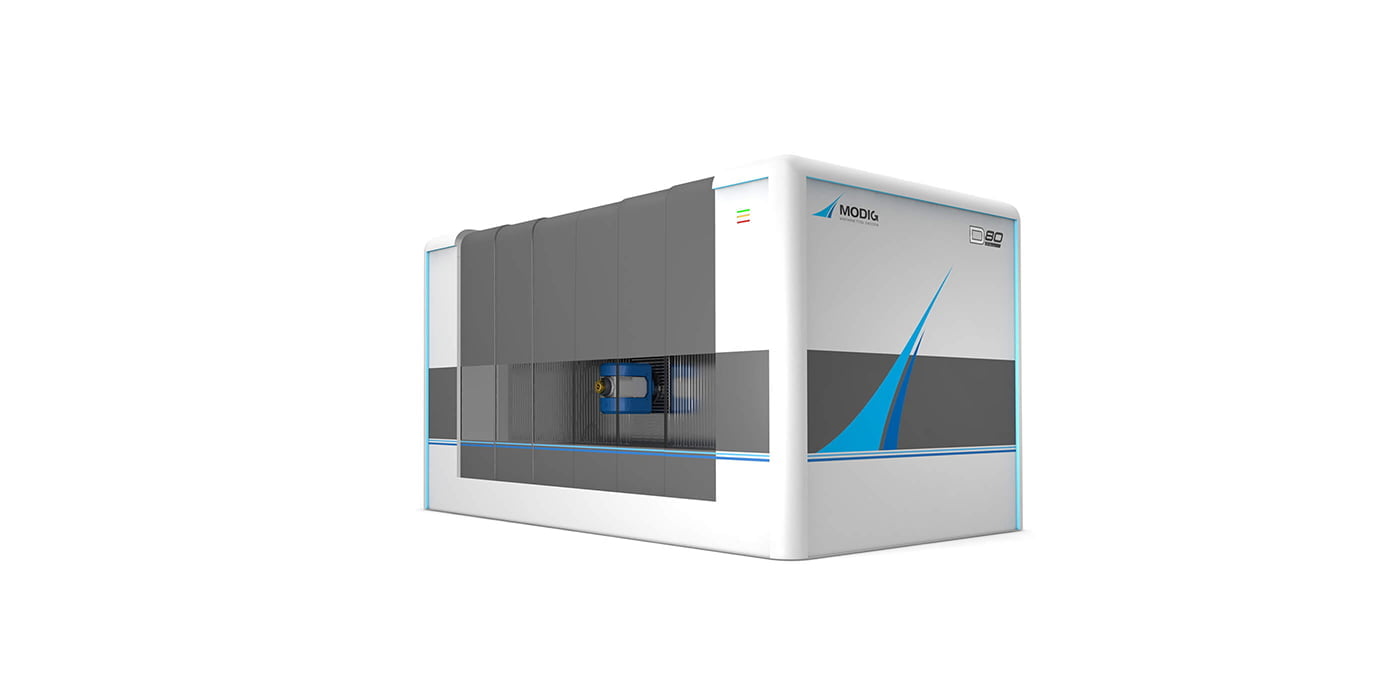

Horizontal machining center MODIG D80

The D80 is a horizontal spindle machining center that process structural aluminum parts clamped on a horizontal fixed T-slot table. Its architecture is based on a moving column structure, sliding on a large and thick cast iron lower platform. The heavy platform allows a very stable machine motion with quite simple foundation requirement as well as easy geometry set.

The working area is fully enclosed, the main automatic door allows easy access and handling of parts. The back of the machine has large doors giving maintenance a clean entry point.

The D80 is designed for medium and large production serials parts, with available 3-, 4- or 5-axis milling application depending on customer request. Accuracy and adaptability make this machining platform well-suited for various market segments.