Industrial Computed Tomography Nikon XT H 450 turbine blade and casting inspection

XT H 450 – Unique micro-focus X-ray and CT system for turbine blade and casting inspection

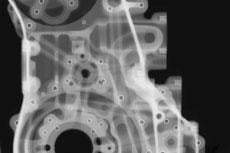

The XT H 450 system offers the necessary source power to penetrate through high density parts and generate a scatter-free CT volume with micron accuracy. The system is available with a flat panel or a proprietary Curved Linear Array (CLA) detector that optimizes the collection of the X-rays without capturing the undesired scattered X-rays.

This linear detector realizes stunning image sharpness and contrast by avoiding image pollution and associated contrast reduction. 450 kV and the CLA are ideal for the inspection of small to medium metal alloy turbine blades and casted parts.

Benefits

- Proprietary 450 kV microfocus X-ray source;

- Run highly accurate inspection on dense turbine blades;

- Easy system operation and low cost-of-ownership;

- Stunning 3D images without scattering provide critical insights;

- High performance image acquisition and volume processing;

- Straightforward inspection automation.

Applications:

- Casting inspection;

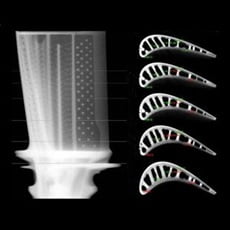

- Turbine blade inspection;

- Micro-CT inspection of dense materials.

Benefits & features

450 kV X-ray source provides power to inspect metal parts

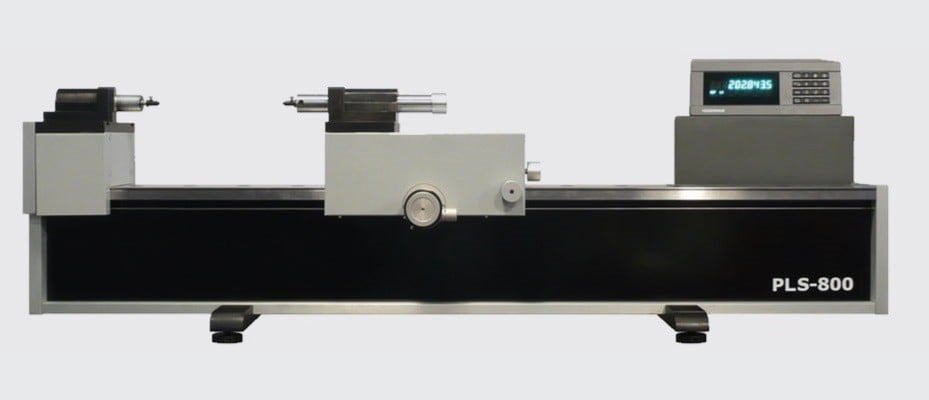

At the core of this powerful equipment is a 450 kV/450 W micro-focus source, offering sufficient X-ray power to penetrate dense specimens, such as turbine blades and casted engine parts.

Through automated inspection and high-speed CT reconstruction, blade manufacturers can run detailed CT inspection of turbine blades (e.g. wall thickness) to optimize the fuel economy of jet engines.

Superior accuracy through proprietary microfocus X-ray source

The proprietary 450 kV/450 W source is the only micro-focus X-ray source at this energy, and delivers 25 micron repeatability and accuracy! As this micro-focus spot size is considerably smaller than existing mini-focus sources, the level of detail that it captures is beyond comparison. As the X-ray spot size of these sources is orders of magnitude smaller compared to minifocus sources, end users benefit from superior resolution, accuracy and a wider array of measurable parts

Customizable macros driving automated measurement workflow

With a maximum specimen diameter of 600 mm and 500 mm length, XT H 450 is a flexible X-ray/CT system that deals with multiple small blades at high magnification, and also large blades and large castings. In a production environment, the shop floor friendly system runs automatic data acquisition and inspection based on blade type, generating pass/fail status for each inspected part.

When taking radiographs of turbine blades, raw images and specific information items, such as blade profiles and inner and outer wall thicknesses, are stored in the database for traceability and further analysis.

Full protective enclosure and continuous fail-to-safe monitoring

XT H systems have a full protective enclosure – compliant to CE and DIN 54113 radiation safety standards and have continuous fail-to-safe monitoring during system operation.

Operation requires no special badges or protective clothing.

Download the brochure