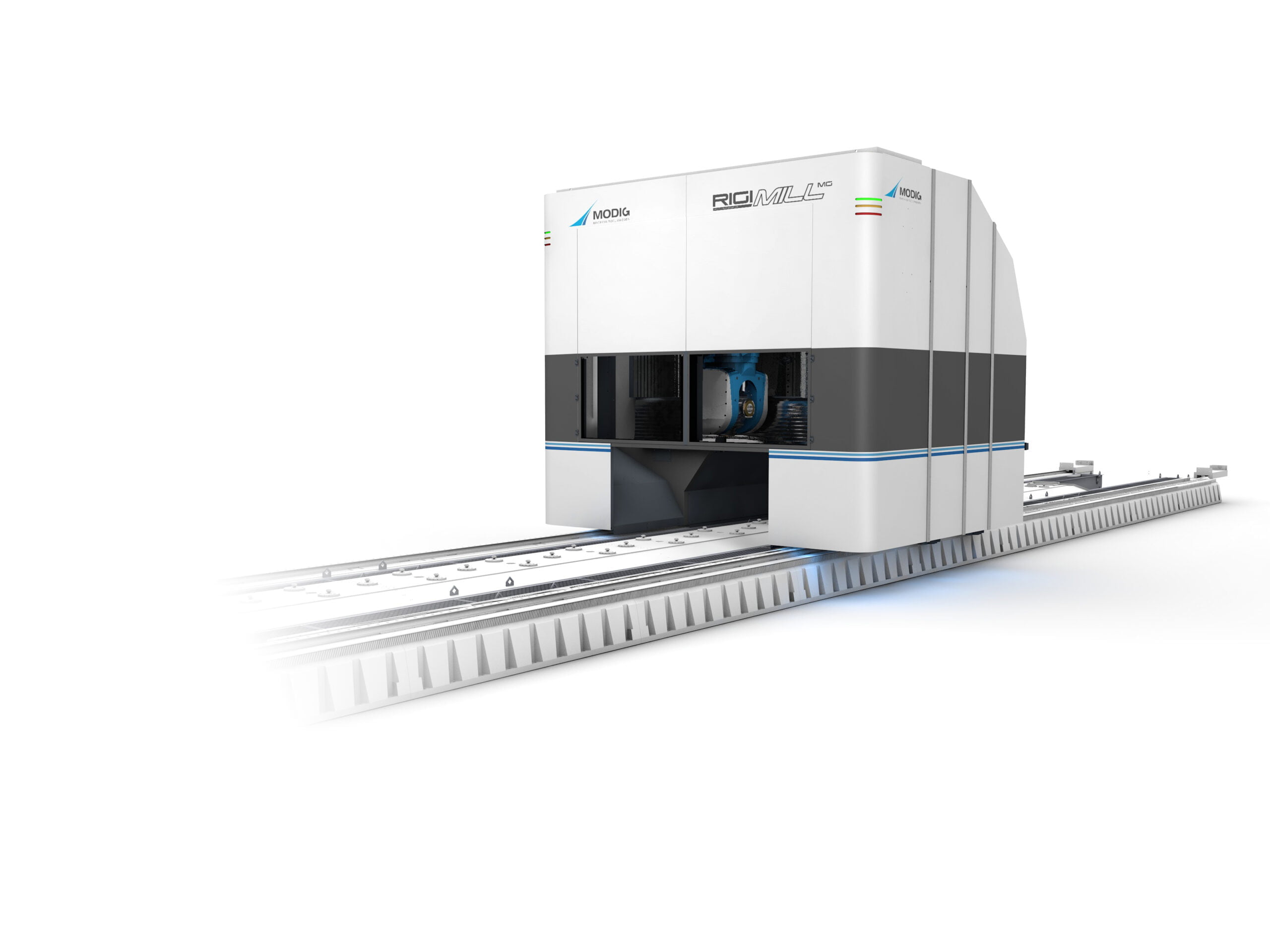

Long bed machining machining center RigiMill MG

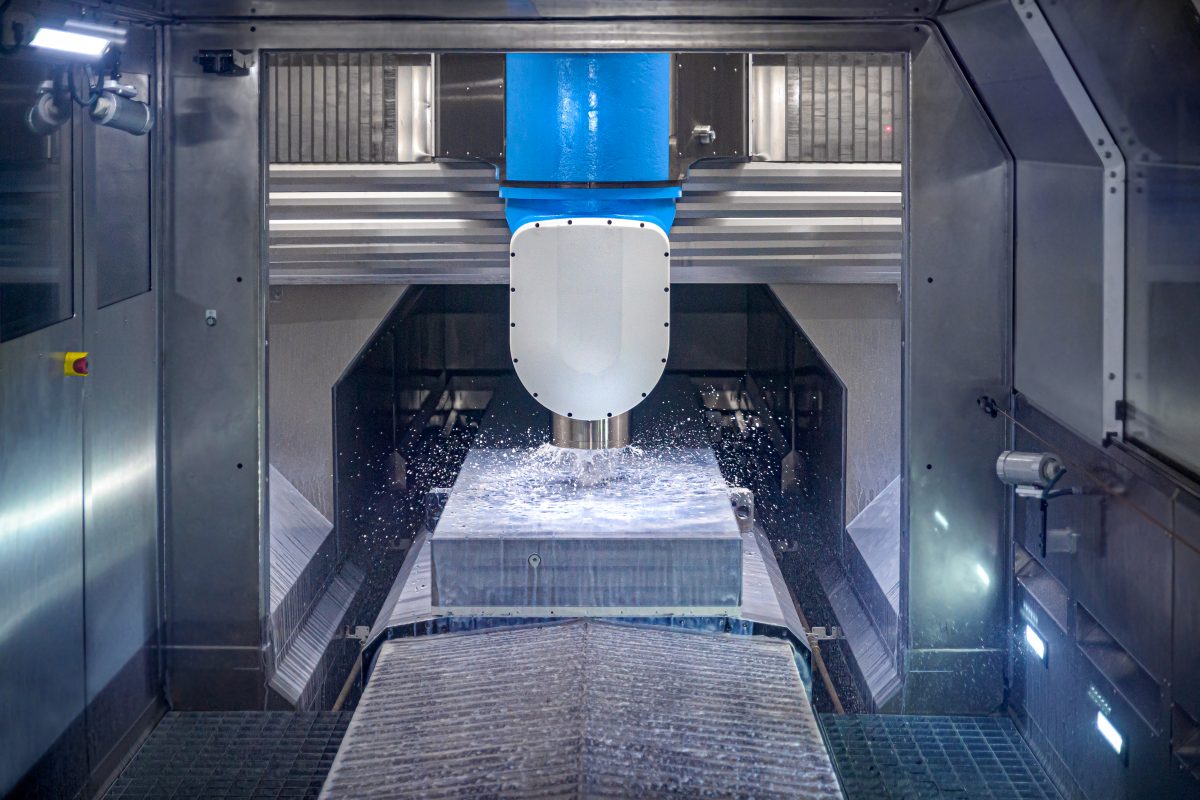

The RigiMill MG has achieved a chip removal rate of 1,000 cubic inches (16.4 liters) per minute in aerospace aluminum and is available with an automatic pallet system up to 950″ (24 m)!

RigiMill Moving Gantry (MG) was developed to produce the fastest chip removal rates in the world. Various spindle configurations achieve chip removal rates up to 55 cubic inches/min (0.9 liter/min) in titanium and 1,000 cubic inches/min (16.4 liters/min) in aluminum, this machine makes it possible to use the same machine for high speed roughing and finishing. Equipped with a single spindle, high speed gantry, the RigiMill MG provides the highest quality and precision of machining either aluminum or hard metals.

It is the unique architecture, as the most compact ever gantry structure with monobloc heavy cast iron bridge structure, as well as, its “no Ram” design through vertical moving cross-rail that offers the most rigid spindle thanks to constant overhang feature, and make the RigiMill MG as being a formidable “beast of efficiency”.

The RigiMill MG purposely reduced scale is an innovative design solution that offers new achievable performances compared to existing machines in the market. It can be configured to each customer’s specific needs and can be extended in the X-axis direction after installation. RigiMill MG is the best manufacturing platform in the world for long part production machining!

CASE STUDY: MACHINING SINGLE AISLE AIRCRAFT WING STRINGERS

From 630” (16 m) aluminum extruded profiles to finished accurate single aisle aircraft stringers: MODIG Technology

164,050 ft (50,000 m) of single aisle aluminum wing stringers are today produced in the MODIG RigiMill MG every month around the world. These typical long and slim parts made of any aluminum or titanium alloys are processed on MODIG RigiMill MG with no length limits. The most productive processes are tackled with our modular palletization system up to 950” (24 m) long pallets or, when footprint allows it, through pendular installation.

Time savings of 64%!

This 630” (16m) aluminum wing stringer was previously machined with a well-known multi machining center in 205 minutes. In the MODIG RigiMill MG the same part was machined in 74 minutes! A time saving of 131 minutes = 64%!

Long life accuracies and surface finishing are provided with the RigiMill’s ultra compact architecture, cast iron monolithic bridge, and moving cross-rail, which offering remarkable rigidity at the spindle.

The RigiMill compactness was purposely designed to offer a formidable agility in any axis’s situations providing with optimal cutting performances and strategies…

Download the brochure