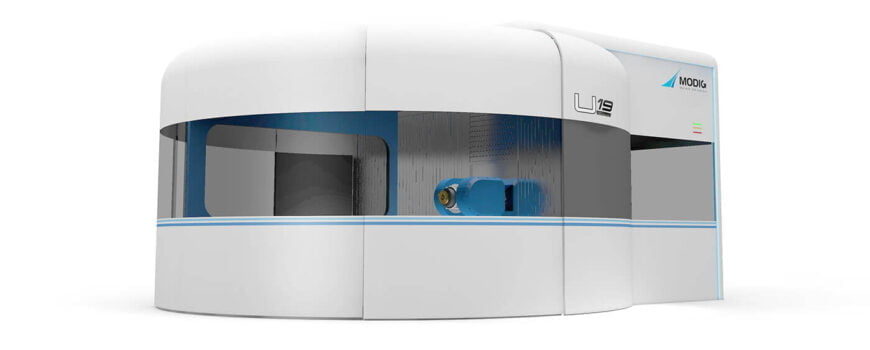

Nikon SLM Solutions - SLM®280 2.0

Experience the future of metal additive manufacturing with the SLM®280 2.0. This innovative system combines precision engineering with advanced technology to deliver unmatched performance and reliability. From prototyping to serial production, the SLM®280 2.0 offers tailored solutions for industries seeking to optimize production processes and drive innovation.

Scalable Production

The SLM®280 2.0 is ideal for medium to high volume metal part production and prototypes, providing a scalable solution to meet your growing production needs.

Accelerated Build Rates

Multi-laser systems in the SLM®280 2.0 achieve build rates up to 80% faster than single-laser configurations, thanks to patented bi-directional powder recoating technology.

Enhanced Safety & Powder Quality

With a PSM powder sieve, the SLM®280 2.0 ensures operator safety and maintains powder quality in an inert atmosphere, reducing operator contact with loose powder.

Efficient Manufacturing Process

Patented bi-directional powder recoating in the SLM®280 2.0 reduces manufacturing time by depositing a new layer of powder in both directions without returning to a “home” position.

Material Flexibility & Quality Assurance

Paired with a Powder Sieving Machine (PSM), the SLM®280 2.0 offers material flexibility while maintaining safety and quality standards, enabling efficient material changeover for adaptable production.

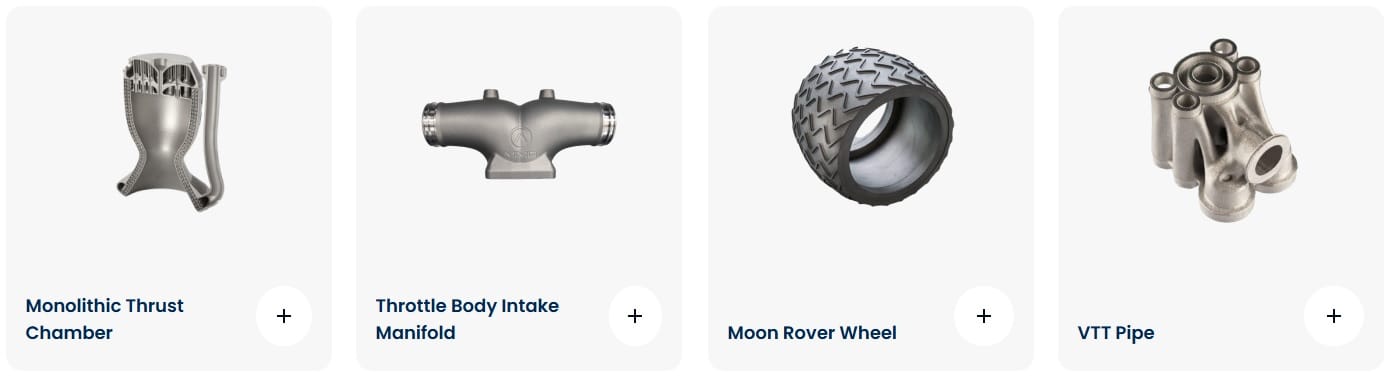

Versatile Applications

The SLM®280 2.0 accommodates a wide range of part sizes and geometries, offering versatility for diverse manufacturing needs, from prototypes to end-use parts.

Precision Engineering

High-precision laser technology and advanced thermal management systems in the SLM®280 2.0 ensure exceptional part accuracy and surface finish, meeting stringent quality standards.

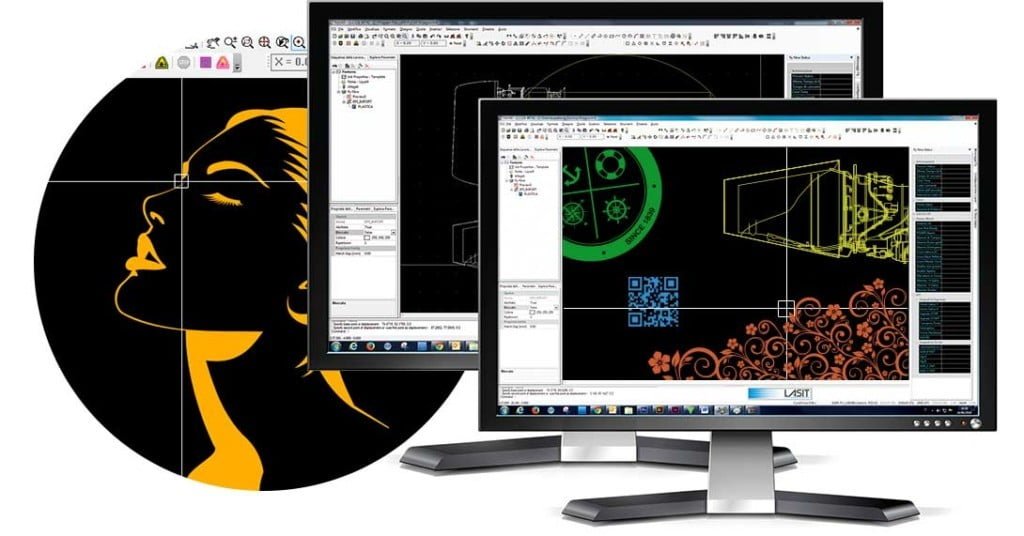

Seamless Integration

The SLM®280 2.0 seamlessly integrates into existing production lines, offering compatibility with advanced software and intuitive interface design for a streamlined workflow.

Cost Efficiency & Waste Reduction

The SLM®280 2.0 minimizes material wastage through precise laser control and efficient powder handling mechanisms, reducing production costs and environmental impact. And to make things easier, every SLM®280 comes with a permanent filter module included.