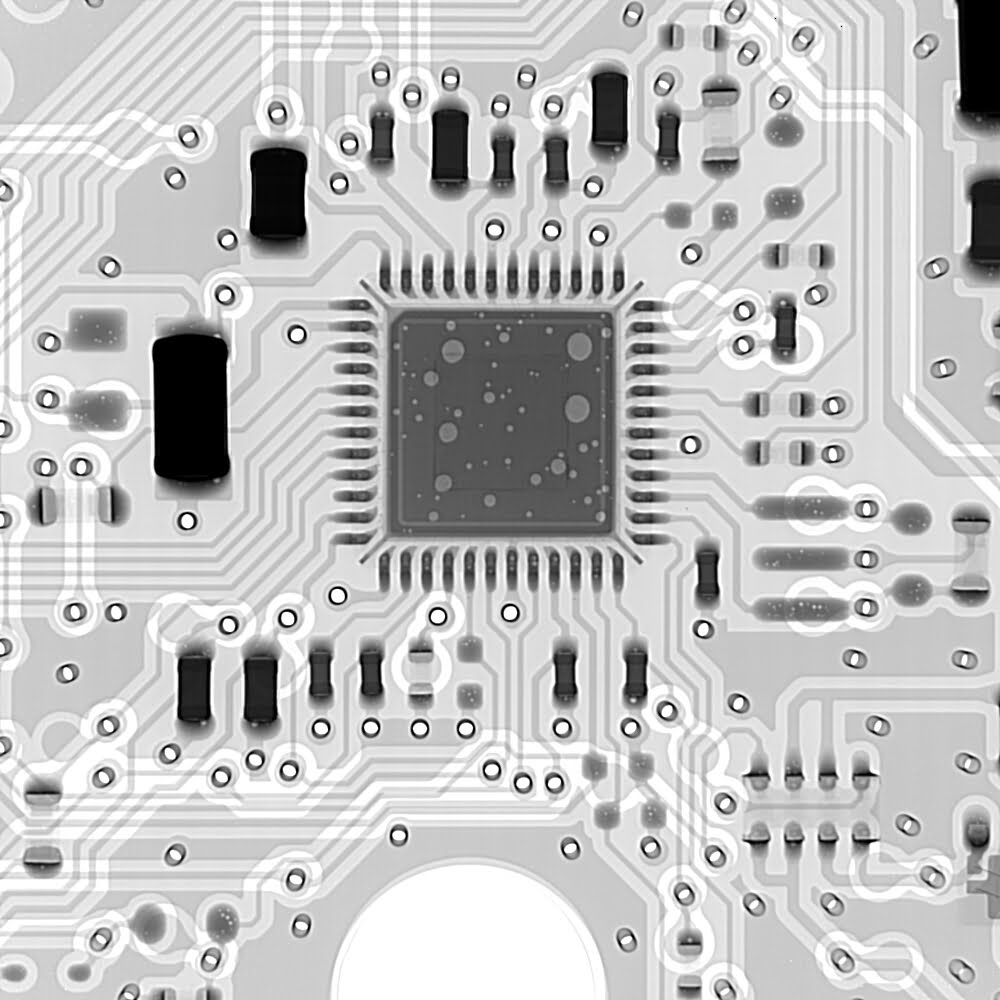

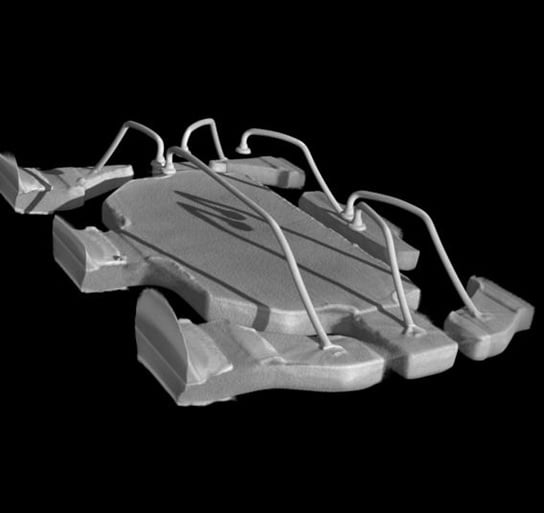

Nikon XT V 130C X-ray inspection of electronic components

XT V 130C – COST-EFFECTIVE X-RAY INSPECTION OF ELECTRONIC COMPONENTS

The XT V 130C is a highly flexible and cost-effective electronics and semiconductor inspection system. The system features a 130 kV/10 watt Nikon Metrology manufactured source, a globally recognized open tube design with integrated generator, and a high-resolution imaging chain.

Through a series of factory and field upgrades, the end-user can configure these systems to their own needs with a higher power source, a rotating sample tray, automatic inspection software, a digital flat panel option, and the ability to add future-proof CT technology.

BENEFITS:

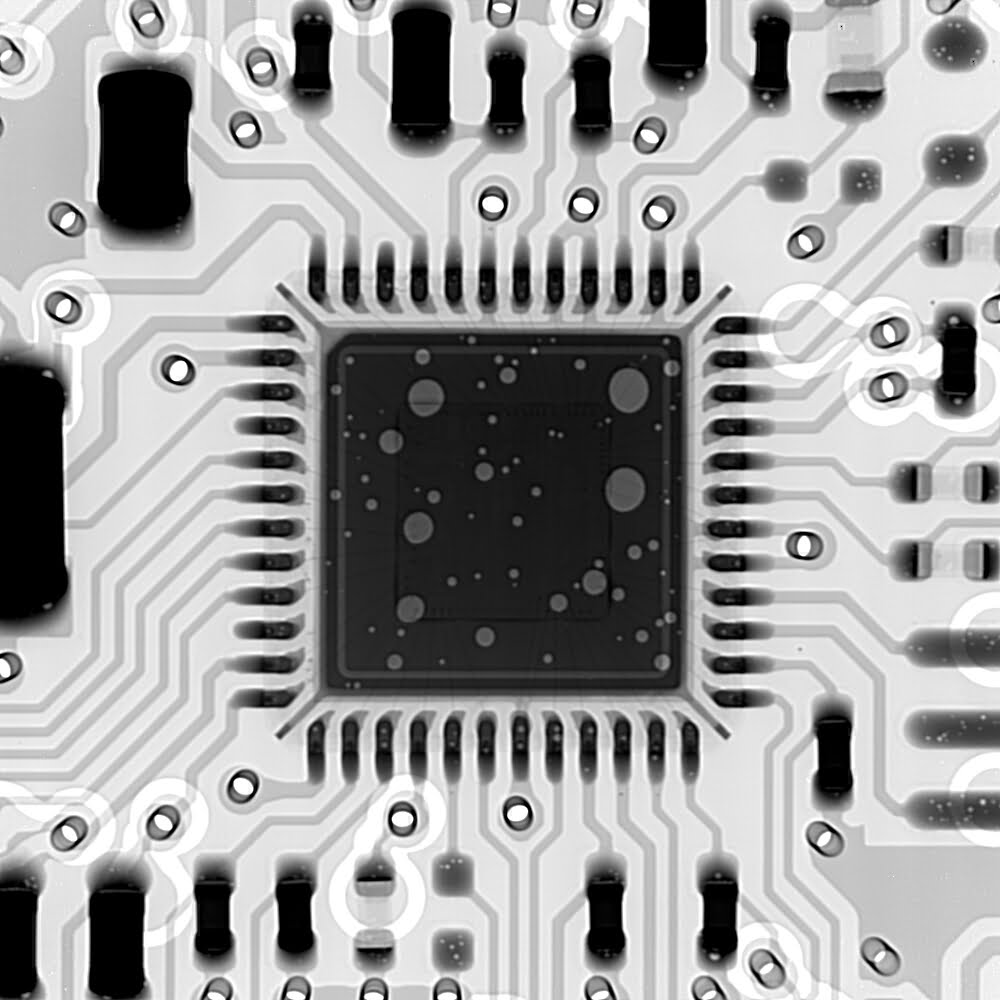

- Proprietary 30-130 kv micro-focus source with 2μm feature recognition

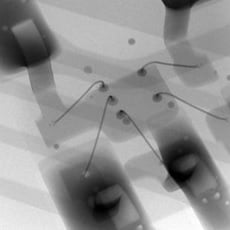

- True 72° manipulator tilting angle allows oblique viewing for easy inspection of internal features

- Large measurement area of 520×520 mm

- Intuitive joystick navigation drives real-time X-ray imaging

- Dual display for combined measurement and real-time analysis

- Low cost of ownership and maintenance with open-tube technology

- Safety as a design criterion

- CT and X.Tract (laminography) ready

BENEFITS & FEATURES

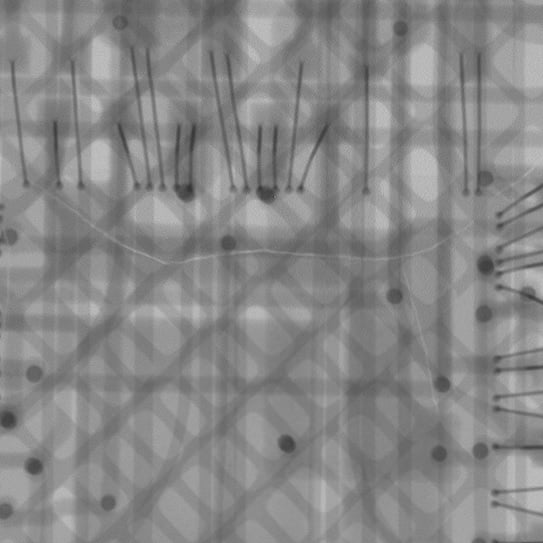

PROPRIETARY 30-130 KV MICRO-FOCUS WITH 3ΜM SPOT SIZE AND 2ΜM FEATURE RECOGNITION

The microfocus source is equipped with a transmission target, offering a 3 micron spot size. XT V 130C system uses a vertical mounted, open-tube X-ray source that guarantees a low cost-of-ownership.

High quality imaging chain reveals all defects

The XT V 130C system incorporates all features to generate high quality images from electronic samples

- Leading proprietary micro-focus source technology

- 1,034x image magnification enables users to zoom in on any specific item of interest

- 1 megapixel flat panel detector with 127 micron pixel pitch

- Accurate control of the power and direction of the emitted X-ray beams

- Qualitative real time X-ray imaging

COMFORTABLE MEASUREMENT AREA OF 520×520 MM

The measurement volume is easily accessible through a large hinged door and can easily hold larger boards or multiple components for automated inspection.

INTUITIVE SOFTWARE INTERFACE

The XT V 130C incorporates the most advanced image capture and analysis software running on the latest specification processing hardware. The resulting data can be saved or exported directly any COM compliant package e.g. Word, Excel, Access and SPC systems. Processing hardware and software are both controlled in-house so that advances in technology can be passed on to the user without delay.

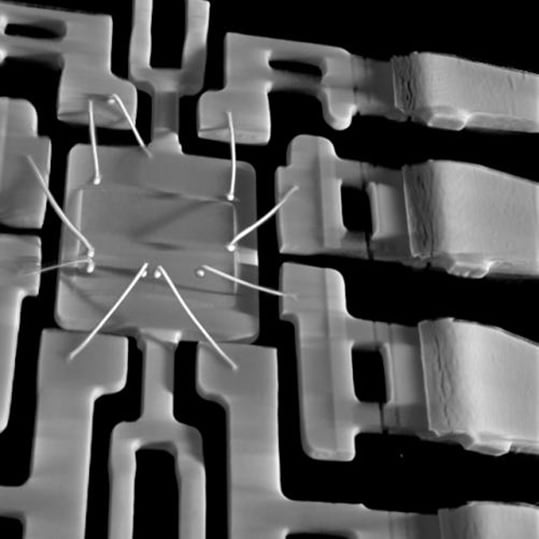

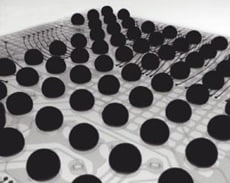

Inspect-X includes special functions for inspection of semiconductor package voids, wire bonding and BGA solder bumps. It also makes use of Microsoft VBA as a scripting/macro language, allowing rapid software customisation to suit specific inspection requirements.

LOW COST OF OWNERSHIP

Nikon’s open X-ray tube development has driven down the size, weight and cost of the system whilst maintaining superior quality and performance. By introducing a patented zero-maintenance cable-less HT generator, the preventative maintenance has been dramatically reduced making the long term cost of ownership considerably lower than any comparable system.

ADVANCED ERGONOMICS FOR EASE OF USE

The XT V 130C has been designed for ease-of-use without compromising performance. A fully adjustable console arm ensures that all system controls are at the operator’s fingertips whether standing or sitting, independent of the operator’s height.

The Windows control screen is laid out logically with all regularly used functions in view on single click buttons while movement of the precision joysticks gives a direct and logical response from both sample manipulator and X-ray image. The system is highly intuitive to operate and as a result, operator training time is significantly reduced.

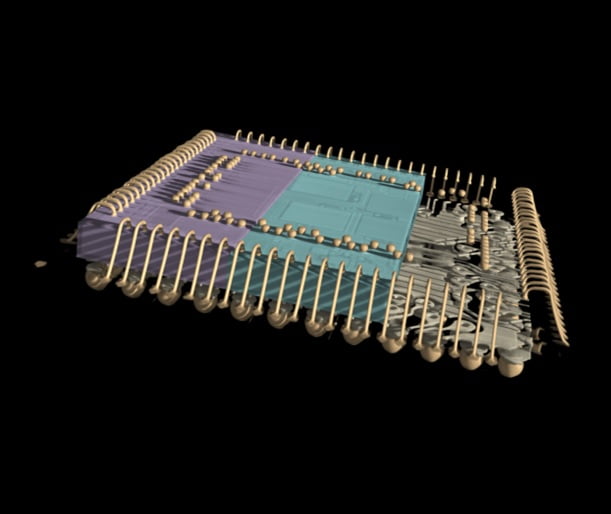

READY FOR CT APPLICATIONS (OPTION)

XT V 130C is pre-configured to turn the system into a CT system. This way 3D images can be reconstructed to gain even more insight into components and sub-assemblies.