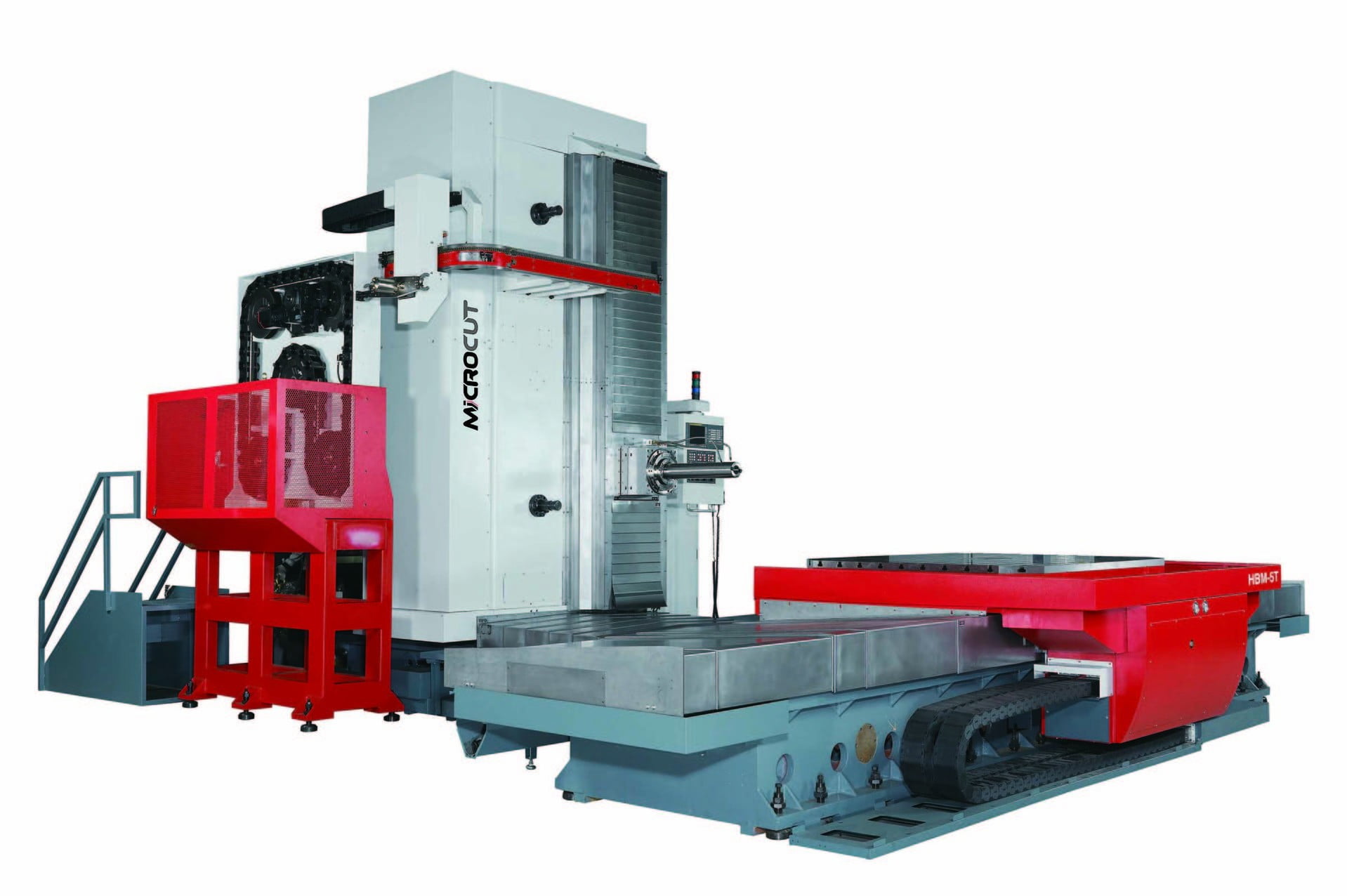

Nikon XT V 160 X-ray high - quality PCB inspection system

XT V 160 high – quality PCB inspection system

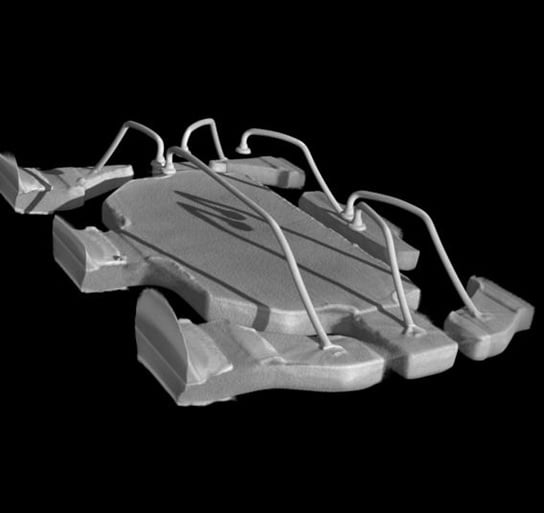

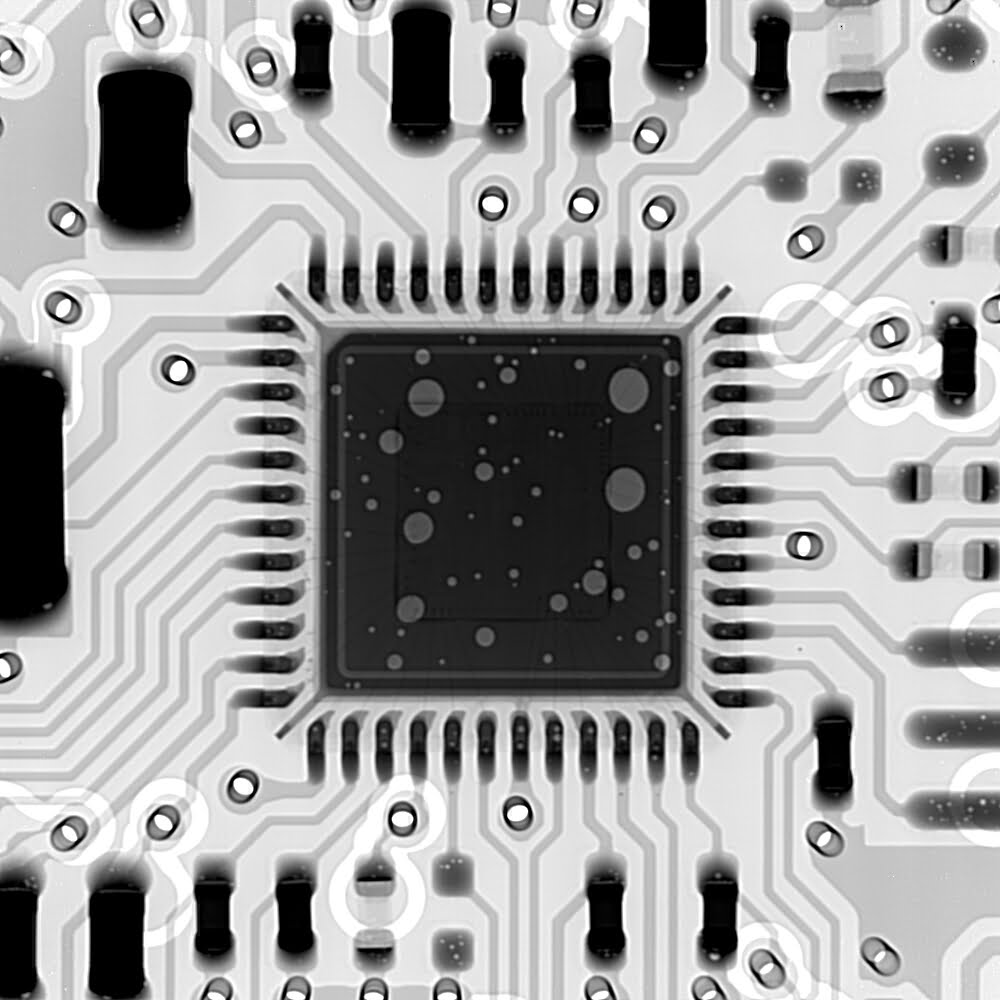

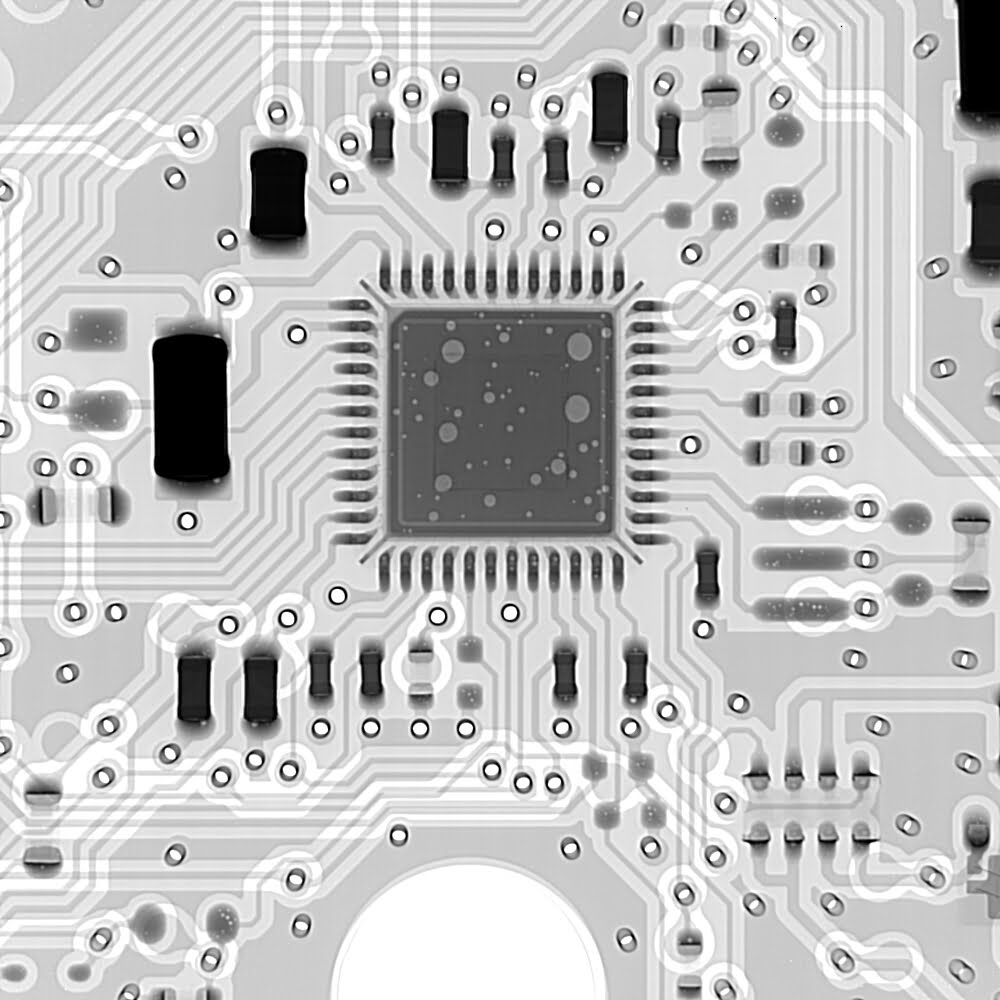

The XT V 160 is specifically designed for use in production lines and failure analysis laboratories. With a precision joystick, system users control the 5-axis sample manipulator. Real-time X-ray allows users to intuitively navigate complex printed circuit boards and electronic components and quickly trace defects. In automated inspection mode, samples can be inspected at highest throughput.

Benefits

- Leading proprietary micro-focus source technology

- Fast automated component inspection through customizable macros

- Intuitive joystick navigation drives real-time X-ray imaging

- 4K Ultra HD display for combined measurement and real-time analysis

- Low cost of ownership and maintenance with open-tube technology

- Safety as a design criterion

- CT and X.Tract (laminography) ready

Benefits & features

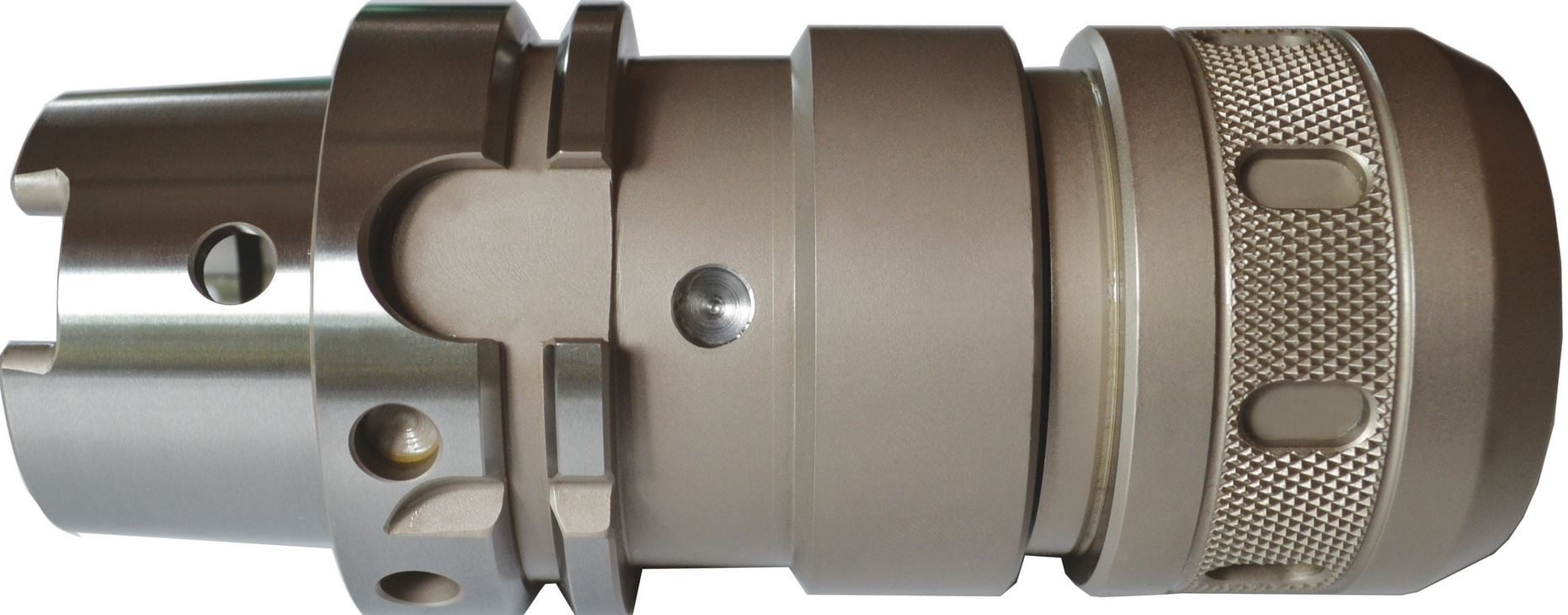

Proprietary NanoTech 160 kV source with submicron spot size

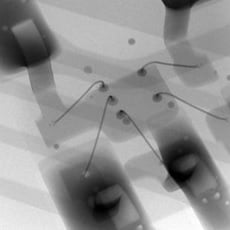

A tightly controlled nanofocus X-ray spot and the latest digital imaging technology ensure that the XT V 160 produces sharp images of micron level features even in the most challenging samples. The advanced electromagnetic lens is computer controlled to ensure that the image remains in focus at all kV settings and the target does not burn when using high power.

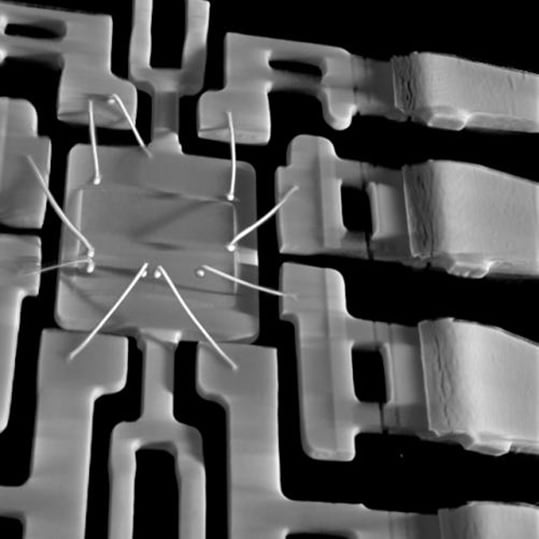

Superior image resolution and magnification reveals all defects

The transmission target design fitted to the XT V160’s X-ray source has an ultra thin output window that enables samples to be safely placed within 250 microns of the focal spot providing up to 36000x system magnification. The patented X-Tek Xi “Open Tube” X-ray source is smaller than any other design and allows X-ray images of fine detail in thick and dense samples to be seen with ease. This high energy vacuum de-mountable unit allows views at steep angles through solder joints and heatsinks without ever running out of energy.

Advanced user friendly software interface

The XT V 160 incorporates the most advanced image capture and analysis software running on the latest specification processing hardware. The resulting data can be saved or exported directly any COM compliant package e.g. Word, Excel, Access and SPC systems. Processing hardware and software are both controlled in-house so that advances in technology can be passed on to the user without delay.

Low cost of ownership and maintenance with open-tube technology

Nikon’s open X-ray tube development has driven down the size, weight and cost of the system whilst maintaining superior quality and performance. By introducing a patented zero-maintenance cable-less HT generator, the preventative maintenance has been dramatically reduced making the long term cost of ownership considerably lower than any comparable system.

Advanced ergonomics for ease of use

The XT V 160 has been designed for ease-of-use without compromising performance. With a fully adjustable console arm which ensures that all system controls are at the operator’s reach whether standing or sitting, independent of the operators height.

The software interface control screen is laid out logically with all regularly used functions in view on single click buttons, while movement of the precision joysticks gives a direct and logical response from both sample manipulator and X-ray image. The system is highly intuitive to operate and as a result, operator training time is significantly reduced.

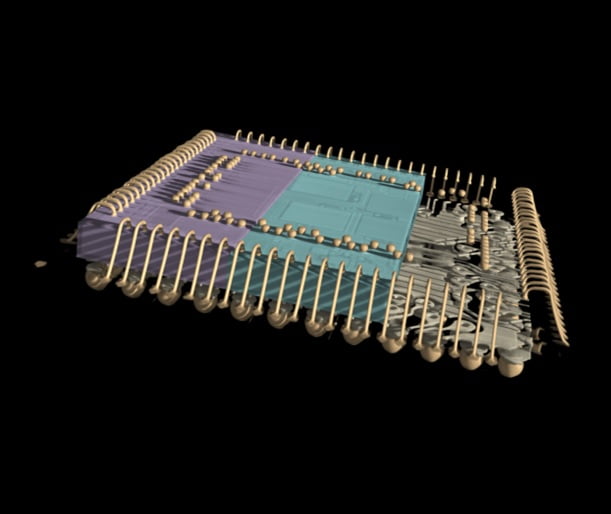

Ready for CT applications (option)

XT V 160 is pre-configured to turn the system into a CT system. This way 3D images can be reconstructed to gain even more insight into components and sub-assemblies.

Download the brochure