Echipament pentru verificarea duritatii prin metoda UCI – Novotest T-U3

The Ultrasonic Contact Impedance (UCI) probe is used for measuring the hardness value of small items, objects with a thin wall, complex form, and to measure the hardness of surface hardened layers.

Built-in camera allows user to picture of testing object and mark tested area with corresponding hardness value.

UCI Hardness Tester NOVOTEST T-U3 has the sealed housing with rubber protective strips, it is ideal for use in workshop, and field conditions with high humidity, dust, etc. The hardness tester has frost-resistant display, which allows user to use the device at any season and in any climatic zone of the Earth.

The device has PC software with a comfortable and intuitive interface.

UCI method for the hardness testing

The UCI hardness measuring method complies to ASTM A1038.

The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring in the case of the testing area minimal thickness (from 1 mm), objects of complex surface shape, and for measuring surface hardened layers hardness.

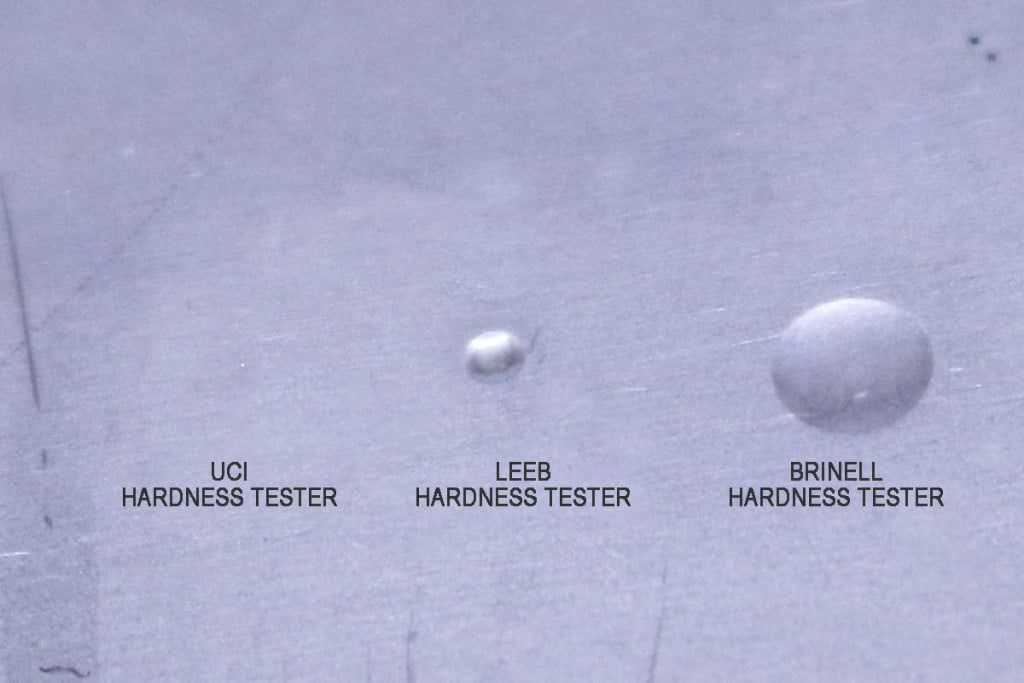

This method is very fast and easy: place the probe on the tested object surface, press the probe with the required effort to the surface and save the hardness value, shown on the display of the device. Small size diamond indenter allows measuring hardness value of all items, which are thicker than 1 mm. The UCI method of hardness testing is the least destructive because the hardness tester NOVOTEST T-UD3 with UCI probe leaves much smaller prints (imprints) than the majority of bench hardness tester would. That’s why a portable hardness tester with UCI probe is the best choice.

We have the CE certificate of conformity for Portable UCI Hardness Tester NOVOTEST T-U3.

- Hardness measurement of any mass products with a thickness more than 1 mm – inaccessible to the dynamic (Leeb) hardness testers (small parts, thin-walled structures, pipes, tanks, steel sheets, articles of complex shape, hardness control of metal coatings, etc.)

- Measuring the hardness of the surface hardened layer

- Small imprint after measuring (mirror surfaces of shafts necks, blades, gear teeth, etc.)

- Wide range of hardness testing

- Various measurement modes

- Calibration of any scale in any range

- Convenience and ease for measurement

- Optimized number of buttons

- Large full color graphic display with bright back-lighting

- Calibrations stored in memory of probe

- Extended temperature range (frost, down to – 40°C)

- Internal memory and communication with PC

- New, intuitive menu with tips on the buttons

- Optional wireless mini printer

- Water resistant case

- Rubber protected bumper

- Has different operating modes:

Graph – the mode of building of graph

Histogram – the mode of building of histogram

Statistics – the mode of statistic

Smart – the mode of filtering of incorrect measurements

| UCI probe types | 1kgf (10N) 2.2 lbf, 5kgf (50N) 11lbf, 10kgf (98N) 22lbf |

| Measuring range (with standard calibration) | HV:230~940; HRC:20~70; HB:90~650. Tensile strength, MPa 370~1740 |

| Measuring accuracy | HV:±3%HV; HRC:±1.5%HRC; HB:±3%HB |

| Standards | ASTM A1038, ASTM E140 |

| Indenter | Diamond indenter (UCI) |

| Measuring direction | Any direction 360° |

| Data storage | Limited only by the memory card |

| Communication | Upload data to PC and export as a spreadsheet (USB cable and software included ) |

| Hardness scale |

|

| Materials |

|

| Data display | Load applied/contact (UCI), Single test result, Max, Min, Average of tests, Number of tests, Deviation, Var. coeff, Histogram, Signal and Smart Mode (Filter of incorrect measurements) |

| Indication | Color LCD display (320×240) |

| Operating environment | Temperature:-20°C~40°C; Humidity: 30%~80%R.H. |

| Power supply | DC 4,5V (3 pcs batteries AA) |

| Instrument dimensions | 160x75x30mm |

| Net weight | Approx. 0.3kg (without probe) |

| Batteries life | Approx. 10 hours |