NOVOTEST T-U3 UCI Hardness Tester

The UCI NOVOTEST T-U3 Hardness Tester has a sealed housing with protective rubber strips and is ideal for use in the workshop and in open spaces where humidity is high. The hardness tester has a frost resistant construction, which allows the user to use the device in any season and in any climate zone on Earth.

The Ultrasonic Contact Probe (UCI) is used to measure the hardness value of small objects, thin-walled objects, complex shapes and to measure the hardness of hardened surface layers.

The built-in camera allows the user to photograph the test object and mark the tested area with the appropriate hardness value.

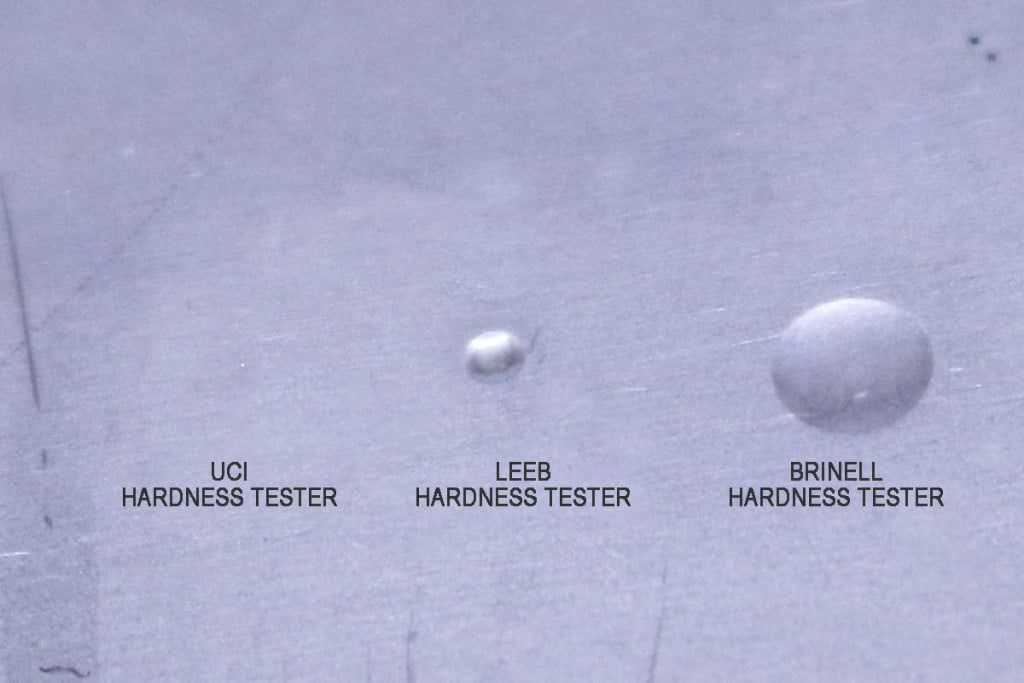

The imprint after measuring the hardness by the UCI method is several microns, and is practically not detected by the naked eye, in comparison with the Leeb method, the imprint of which is about 500 microns in diameter, depending on the hardness. It also makes it possible to measure the hardness of hardened layers of materials (nitriding, cementation, etc.)

Different modes of operation:

- Graph – how to build the graph

- Histogram – how to construct the histogram

- Statistics – provides statistics for the current set of measurements

- Smart – filters out incorrect measurements.

Download the brochure