Lasik laser marking system FlexiMark

Product Description

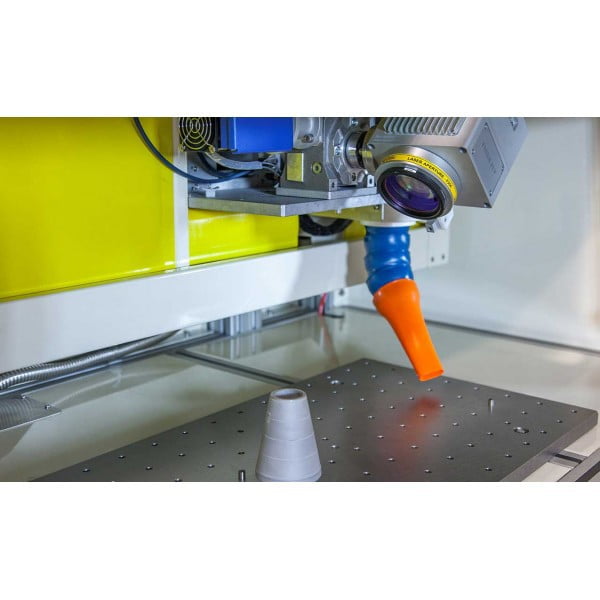

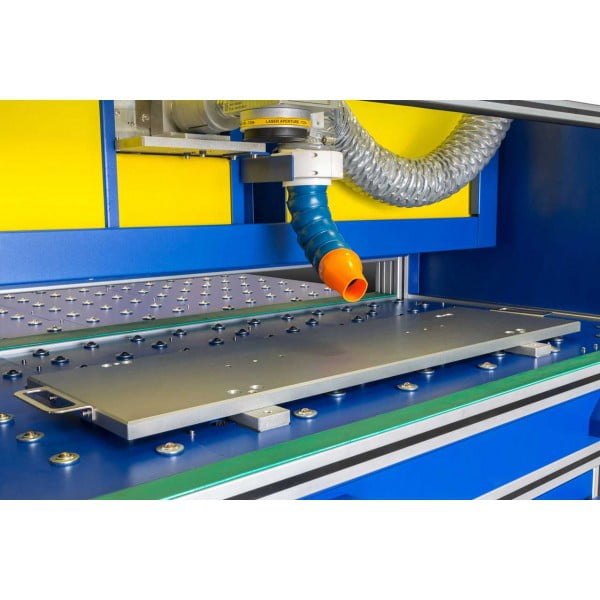

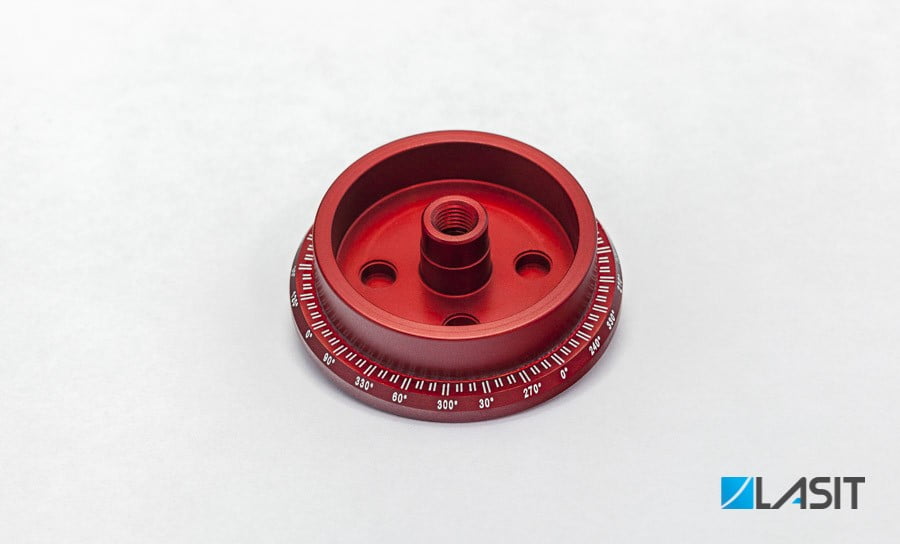

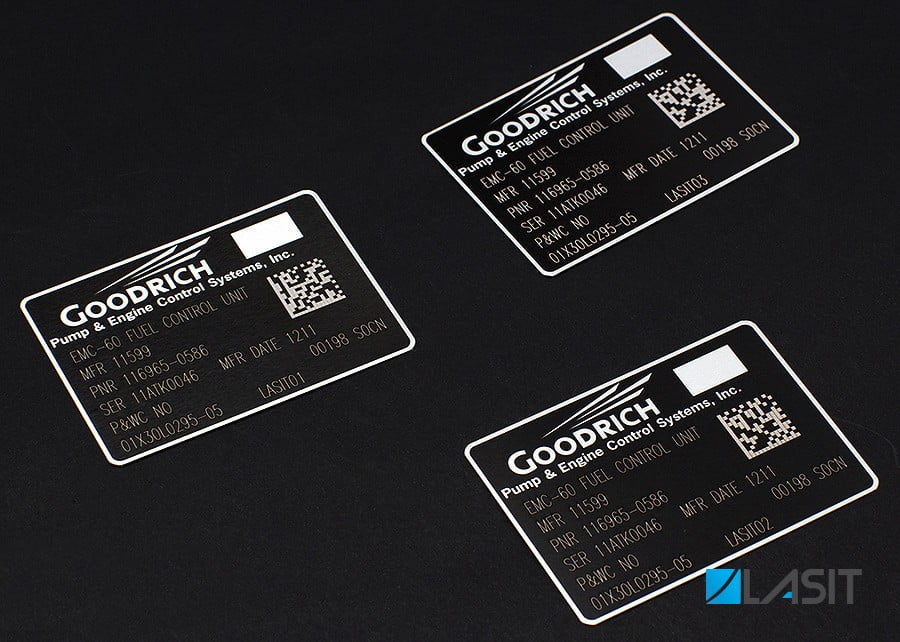

The FlexyMark laser system offers great flexibility in marking providing ample space for both large, complex parts as well as large trays with arrays of parts. The system comes with a wide access pneumatically controlled door, a pull-out type drawer for quick and easy access to parts, and a modular perforated table for easy fixturing of parts, and an optional rotary device for marking or wrapping of logos on cylindrical parts. The machine is ergonomically designed for operator ease of use during extended periods of operation. The optional pass through provides easy access to move parts through without opening the door. The machine comes standard with and X stroke of 800 mm and a Z stroke of 300 mm. A rotary indexer (“C” axis) can be added for marking text or wrapping logos, data matrix, bar codes, around cylindrical parts. In addition and optional Rotating Scan head (theta axis) can be added for marking conical shapes or multiple cylindrical shapes. All the axes are driven by motors configured with encoders controlled by FlyCAD software. The machine offers high accuracy and repeatability due to the rigid structure and Bosch structural frame profile. It is further reinforced with strong powder coated steel brackets. The X axis is constructed of precision ground steel on which the guide rails are mounted. The precision ball screws offer exceptional accuracy. The close looped motors are controlled by encoder.

Download the brochure