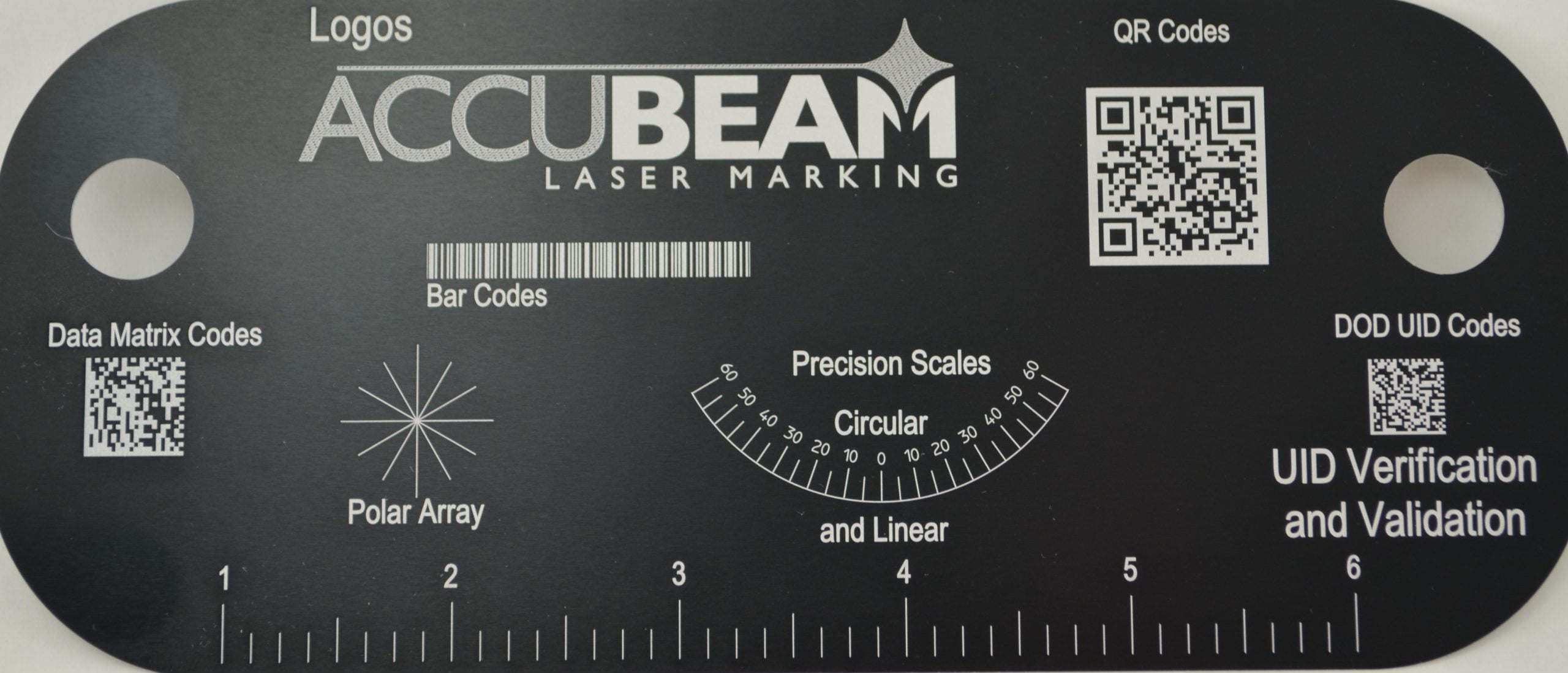

Laser marking system Lasit LabelMark

Product Description

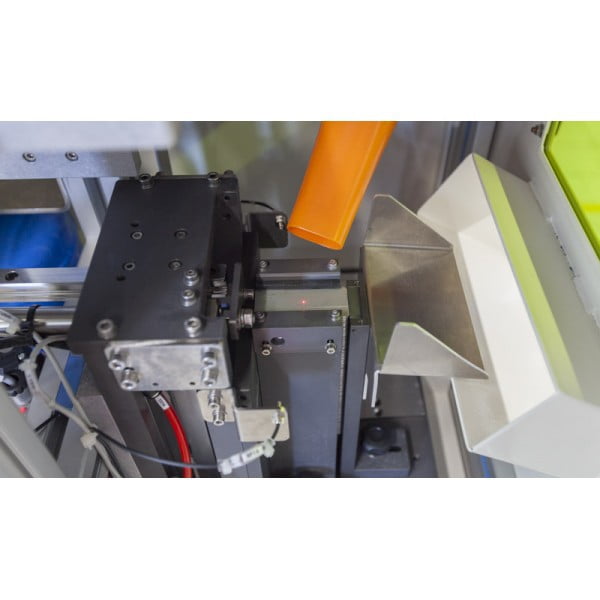

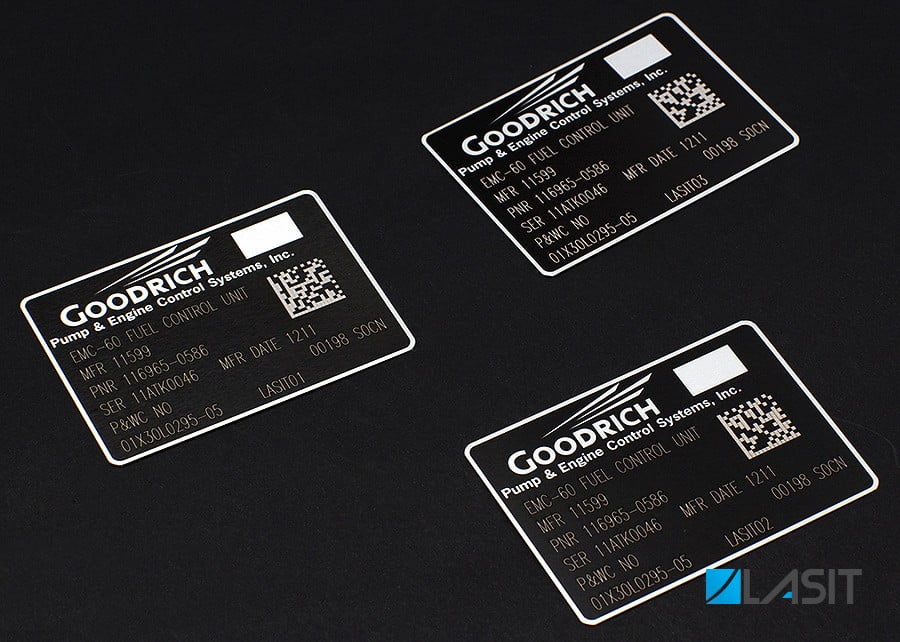

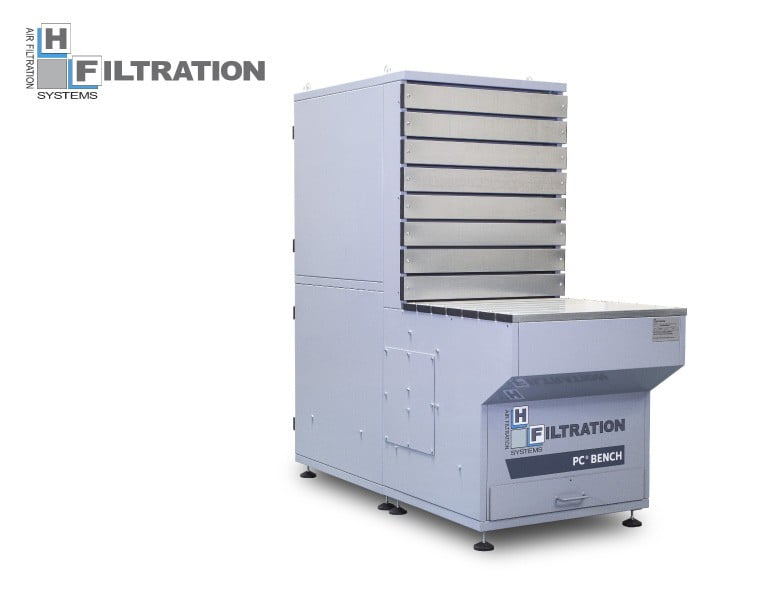

LabelMark is a laser engraver equipped with a charger for the marking in automatic plates of different sizes.

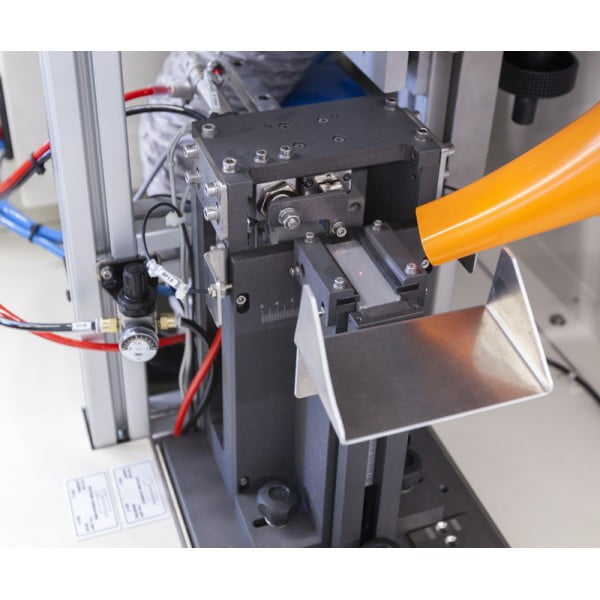

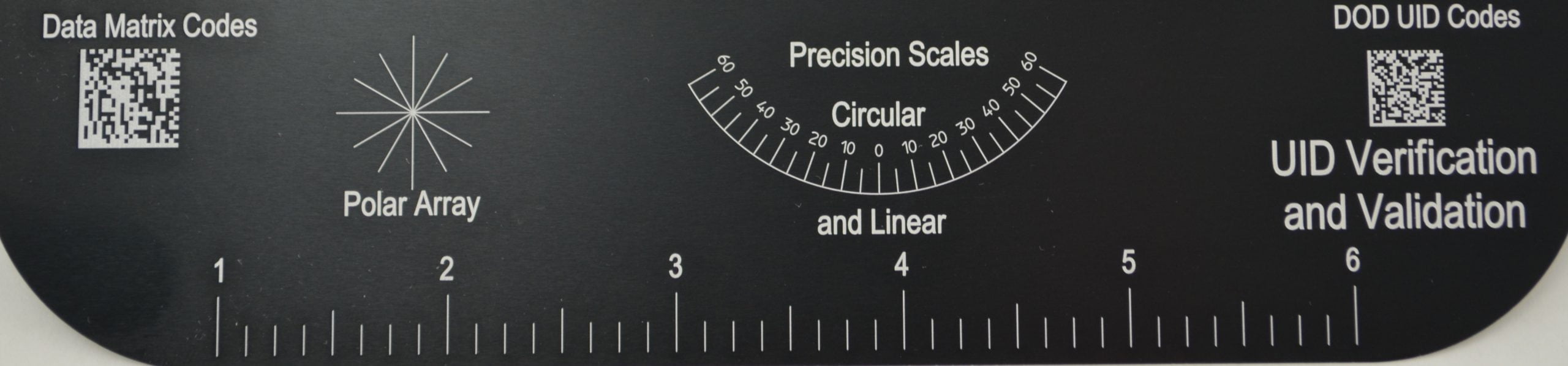

It ‘a marking system is fully integrated, complete with laser active optical fibers, cabin door with balancers, charger label height 200mm with flip through top with adjustable width and length, sewage suction.

The operation of the laser marker is very intuitive because the operator has to do is open the charger and adjust the beats based on the size of the plate choice.

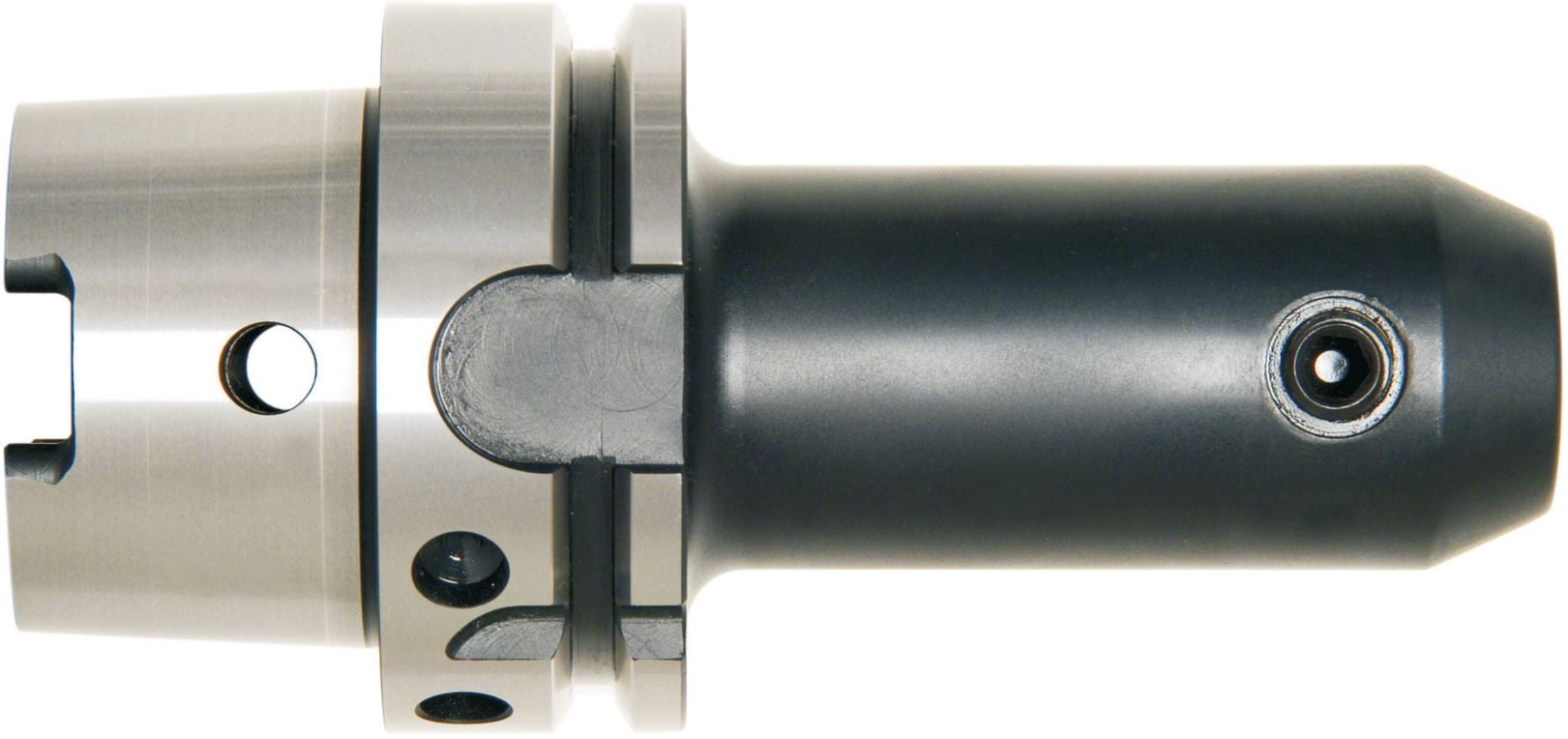

Place the stack of plates, the system runs automatically: a piston pushes the stack joke compared to two fixed supports prepared for the correct focus distance and starts marking.

Whenever the laser engraver concludes the marking plate, another piston pushes away the plate.

The discharge of the name plate takes place in a suitable conveyor or on an optional stacker so as to maintain the same sequence of writing.

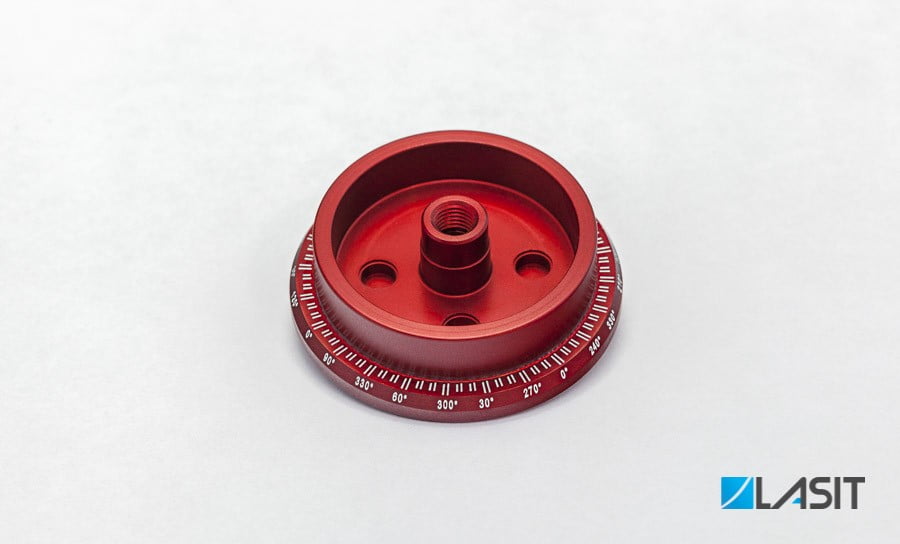

E ‘can also work on a removable shelf area of 150x150mm so as to mark different details on the plates (maximum height particular 100mm).

LabelMark is supplied with HP PC with Win7 64-bit professional, already prepared for connection in the corporate network.

Installation of Fly CAD and FlyControl PC in the technical preparation for the outside line of HP programmiPC with Win7 64-bit professional, machine already set up for networking company.

Installation of Fly CAD and FlyControl PC in the technical preparation for the off-line program.

Download the brochure