Laser marking system - Lasit RollerCoaster

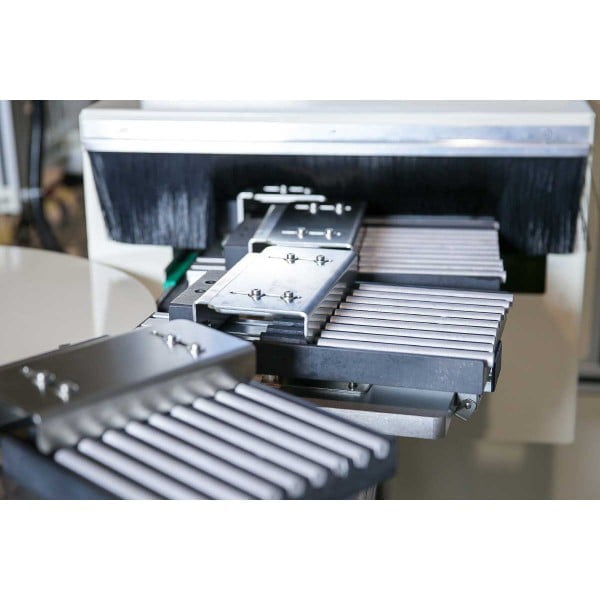

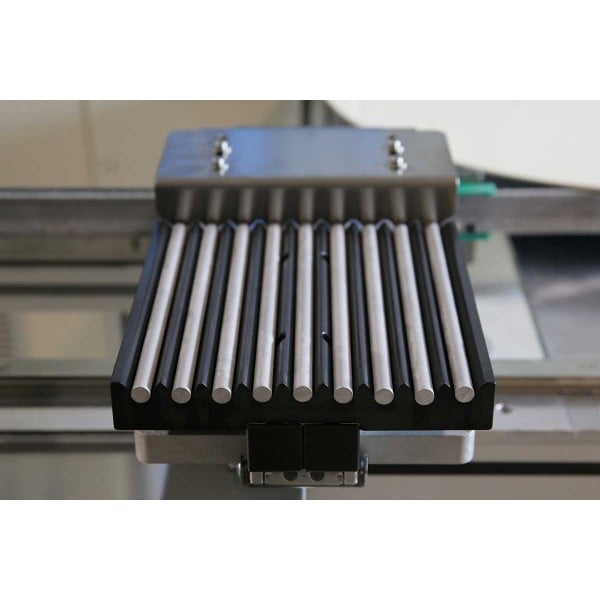

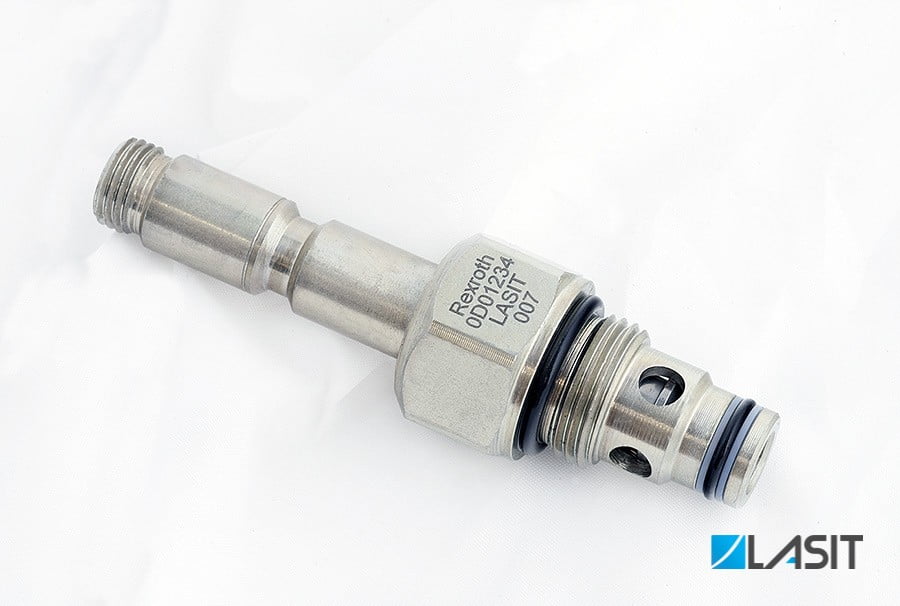

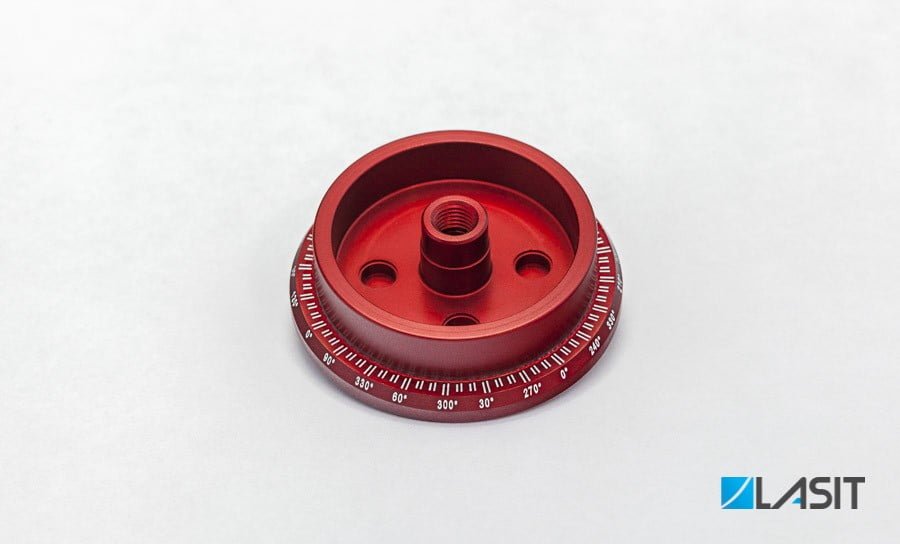

The RollerCoaster system is an automatic laser marking system with a closed loop line for the machining of work pieces placed on a pallet. These parts can be cylindrical placed in pallets that continuously travel through the line, are indexed to be marked and then are automatically unloaded. The overall dimensions as well as the numbers of pallets can be customized and defined based on the production needs of the customer. Cylindrical parts are loaded quickly into the fixture with varying diameters and the pallets move around in a loop to be marked and unloaded. The marking area has a built in stop to index the pallet which consistently produces accurate, precise, repeatable marks. The programmable and motorized Z axis controlled from a PC provides for automatic marking on the same pallet with parts that have varying heights. Once the marking is completed, it can be downloaded automatically with a rollover system. The line speed is then adjusted by an inverter. The system can be installed with different types of lasers according to the material to be marked and a vision system can be integrated. The operator loads the pieces on the several pallets and he starts the cycle: the first pallet – and then all the other pallets in a continuous loop – is transported in the marking chamber to be indexed and marked. The pallet with the marked pieces is then released and it passes into the automatic discharge station where it is overturned and the marked pieces run on a specific slide while the empty pallet returns to the loading station. The system is available with a full range of laser systems depending on the material to be marked. An optional vision system can be integrated as well. The pallets are loaded prior to marking and the laser starts to mark each pallet in a continuous loop. Each pallet is transported to the marking chamber to be indexed and marked. After the marking is completed the pallet is released and then passes to the automatic discharge station (if included in the system) where it continues in the loop on a slide and returns to the loading station.

Download the brochure