Laser marking station Lasit TowerLight

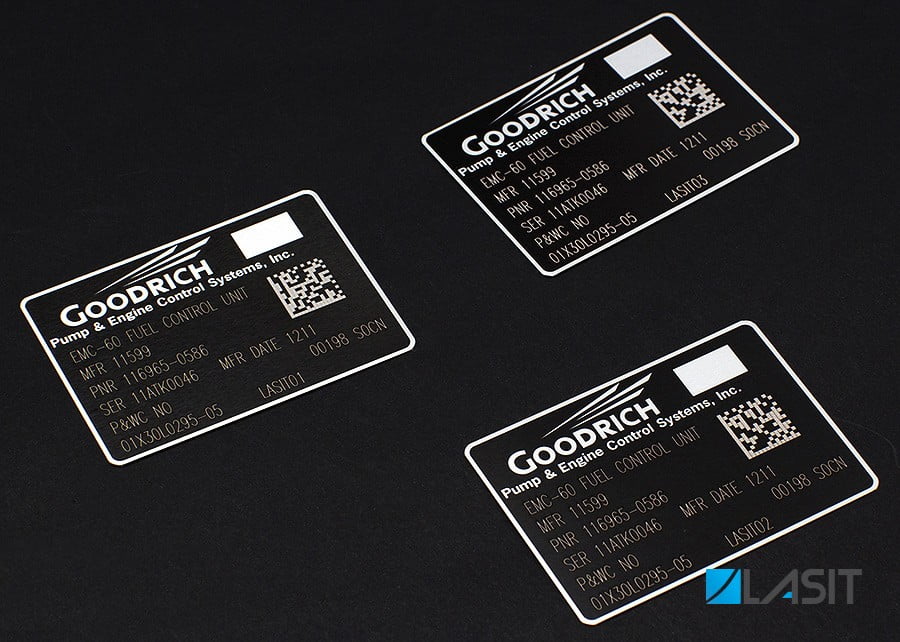

Product Description

TowerMark Light is a laser marking system that is mainly characterized by its pneumatic door.

The working area is easily accessed and centering of the marks is convenient even with complex part.

The door closing control is located on the control console: which is equipped with an anti-crushing system, it closes safely.

Upon closing the door, the marking cycle starts and after the marking, the door opens automatically with safety interlocks.

If a pneumatic system is not needed, a manual hinged door is available as an options.

The marked area is always well visible with the door closed due to the large viewing glass and internal lighting system.

All the components are housed in the structure (including the exhaust system). The working plan is 620x450mm and the marking area can be from ø100mm up to ø220mm depending on the lens installed.

The Z axis, operated by the FlyCAD marking software, provides for marking of parts from 0 to 350mm high.

The motors have encoder feedback and can also be controlled with a joystick which works in conjunction with the Smart Focus system.

These features allow for instant focus which saves time in marking different parts of varying geometries.

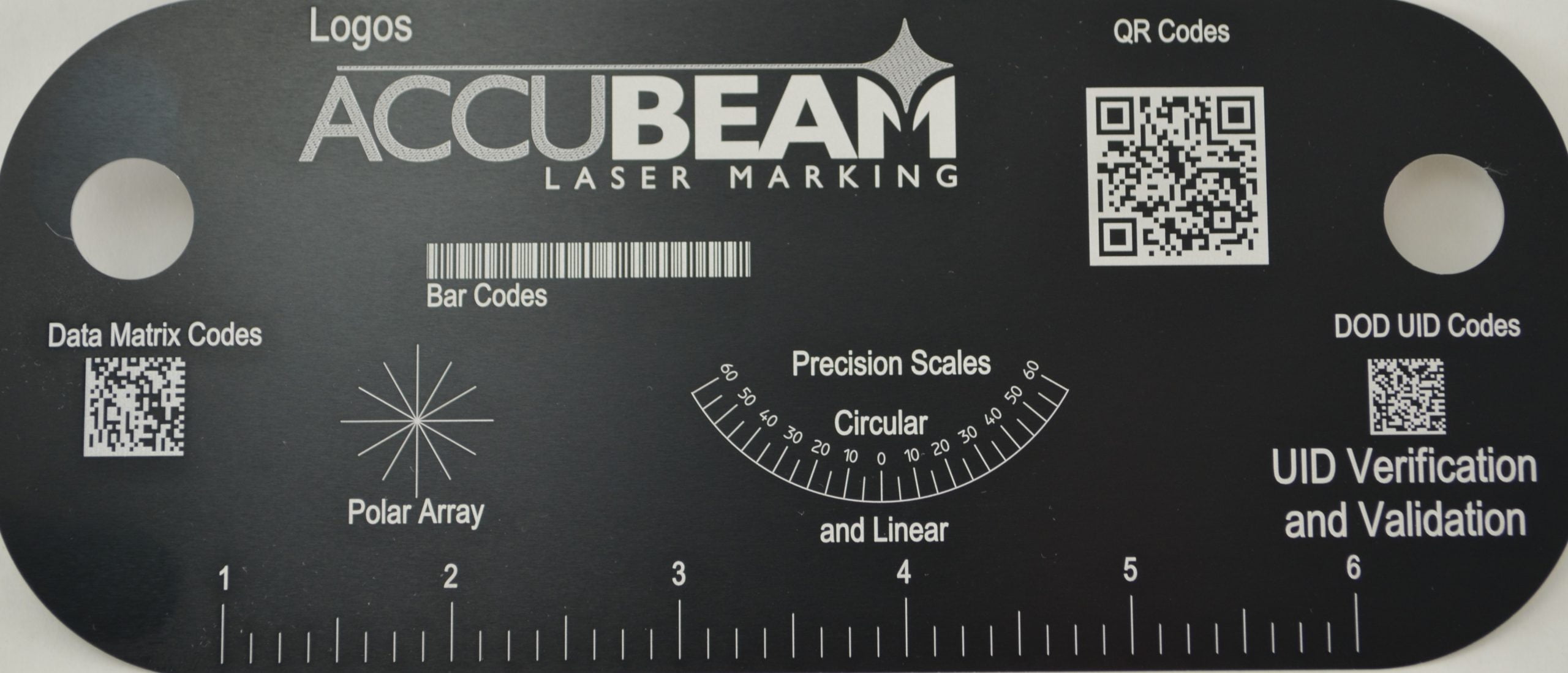

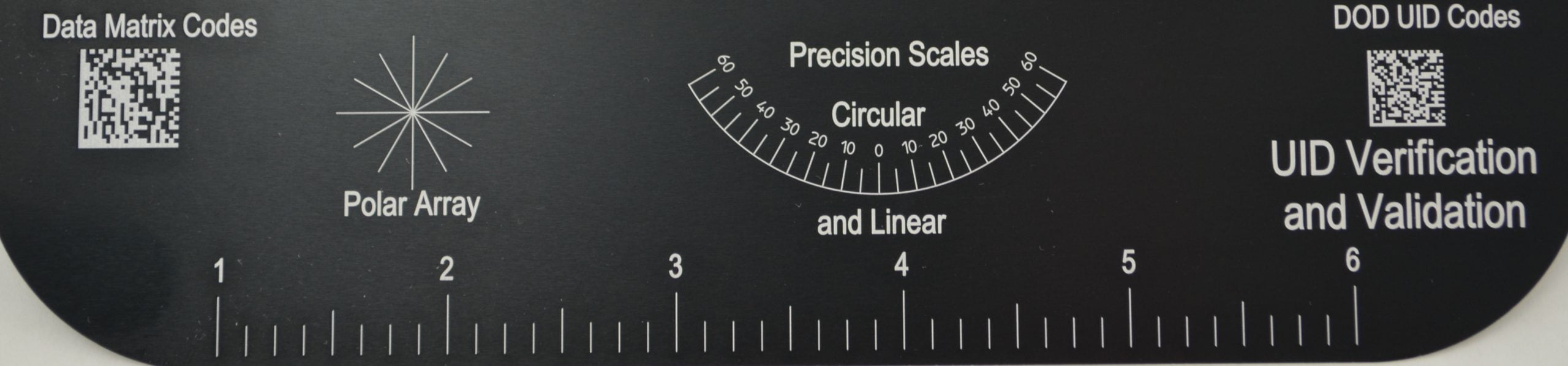

This system can be used with all surfaces including flat, cylindrical and curved shapes or corners.

The system allows the operator to find the correct position and focus for optimal marking without spending time to find it manually.

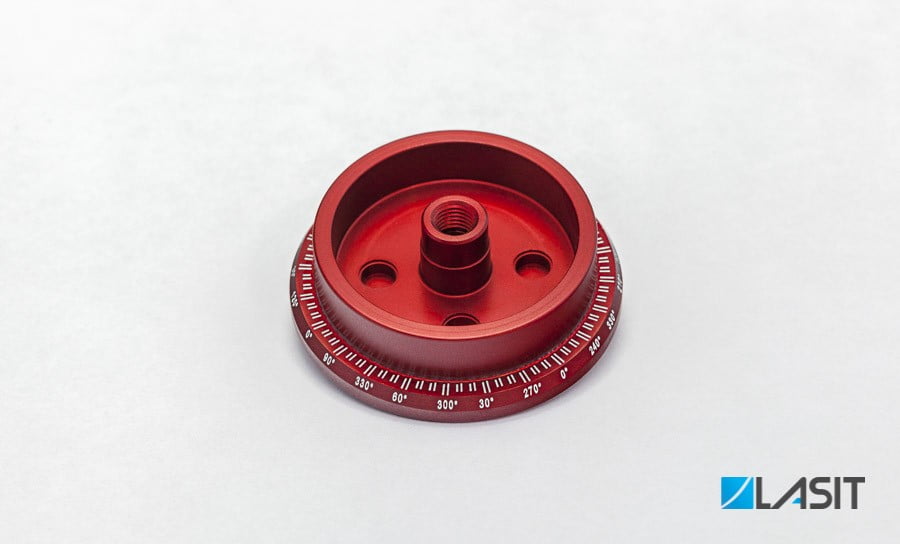

Another useful feature is a rotating axis (rotary indexer) for wrapping marks, logos, text around cylindrical parts.

Logos can be seamlessly marked around the curved surface. In addition, both standard and custom rotary axes are available with through hole collets, 5 collets with grippers for heavy or large diameter parts, and 3 Jaw chucks. Sheet metal clamps and tighteners with automatic advancement are available with the system to secure materials when cutting metals such as gold and silver or other.

Download the brochure