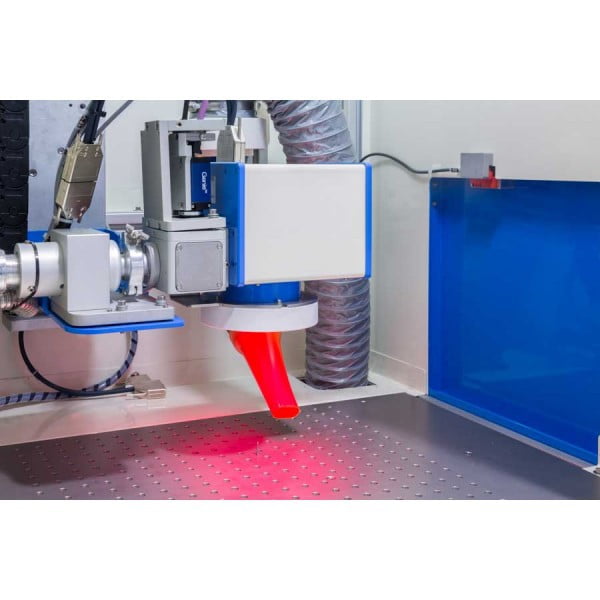

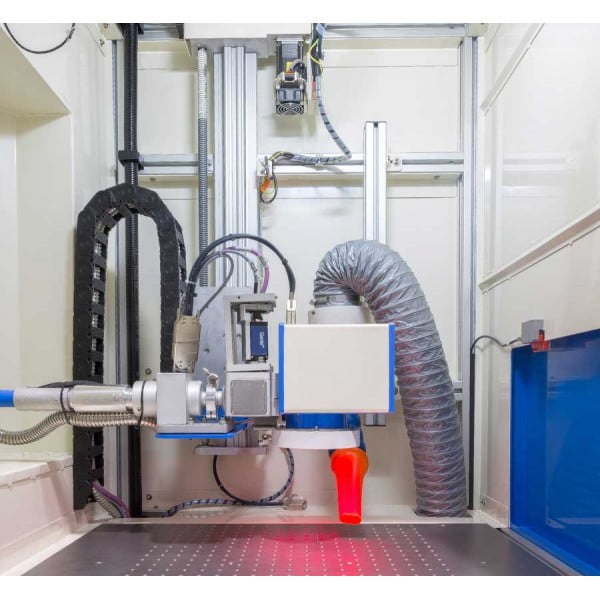

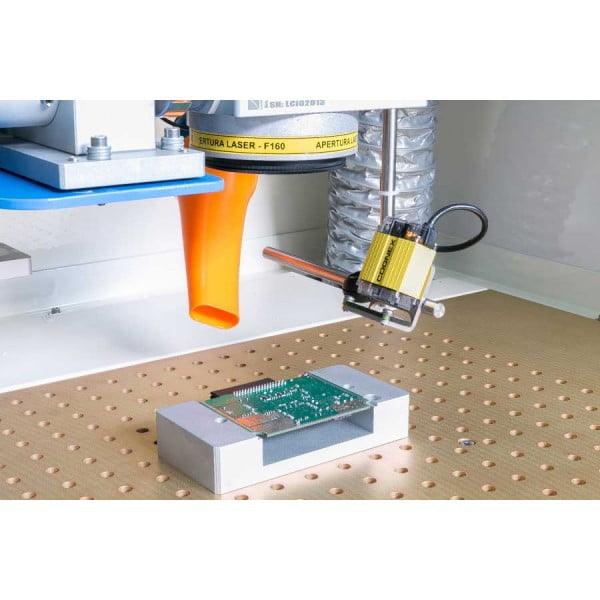

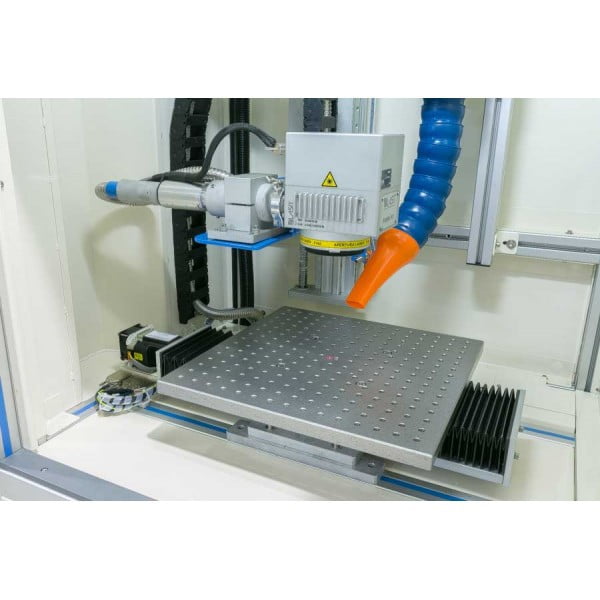

Lasik laser marking system TowerMark

Product Description

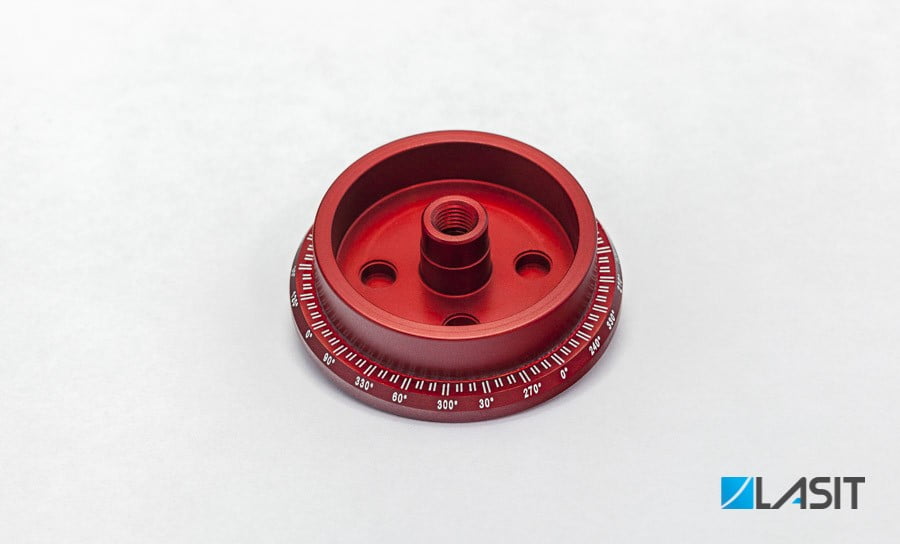

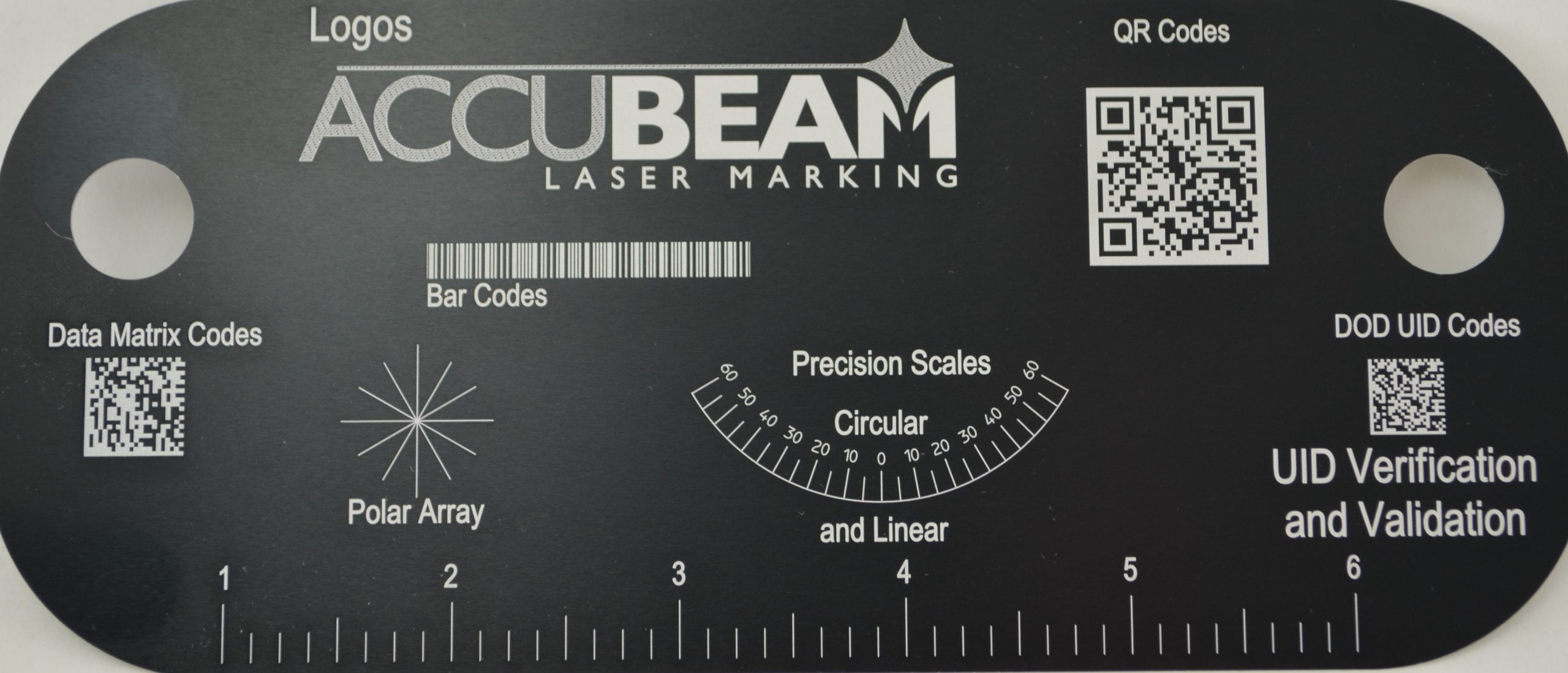

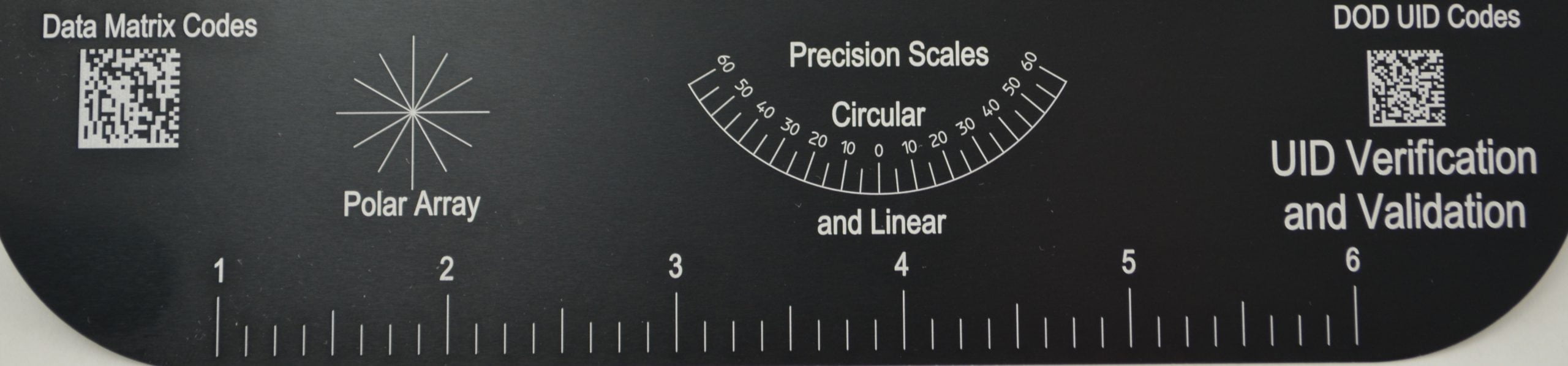

The TowerMark is an extremely versatile marking system and can be used both manually and in combination with a robot for loading/unloading. All components are housed inside the cabinet below which is part of the main structure. The system can be moved easily with a pallet jack or is also available with wheels. The door can be both manual and pneumatic. The large viewing glass and interior lighting system provide a clear view of the objects to be engraved and simplify their positioning. The working area is 620x450mm and the marking area ranges from 100mm up to ø310mm depending on the choice of lens (100mm, 160mm, 254mm, 320mm, 420mm). The Z axis, operated by the FlyCAD marking software provides for marking of various thicknesses from 0 to 450 mm. The motors with encoder feedback can also be controlled via the Joystick and the SmartFocus providing instantaneous focus. With these features the operator can easily find the correct position and focus on all flat, cylindrical and complex geometries with curves and special angles. Another optional feature is a special pull out drawer to speed up the loading and the unloading of the pieces to be engraved. Other special options include a rotary axis (rotary indexer, 5 collet, through hole rotary) providing another axis for the continuous marking of cylindrical parts, a rotating scan head for the marking of cylindrical and angled parts up to 90 degrees, and a table with a 300 mm stroke to increase the working area.

Download the brochure