Laser marking station Lasit TowerSlide X

Product Description

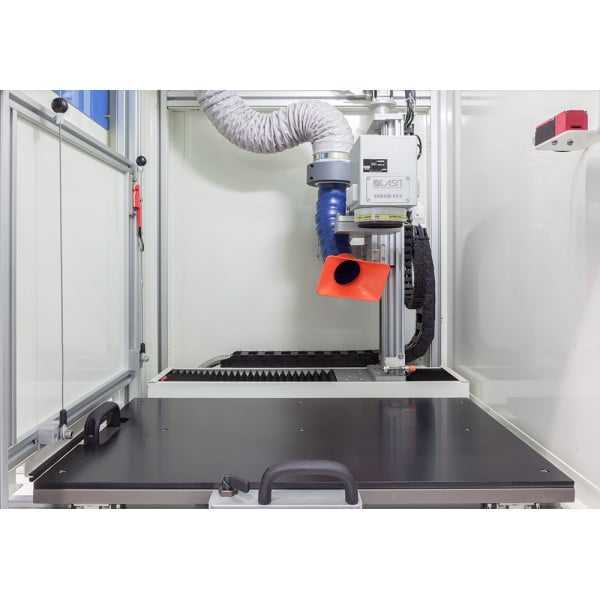

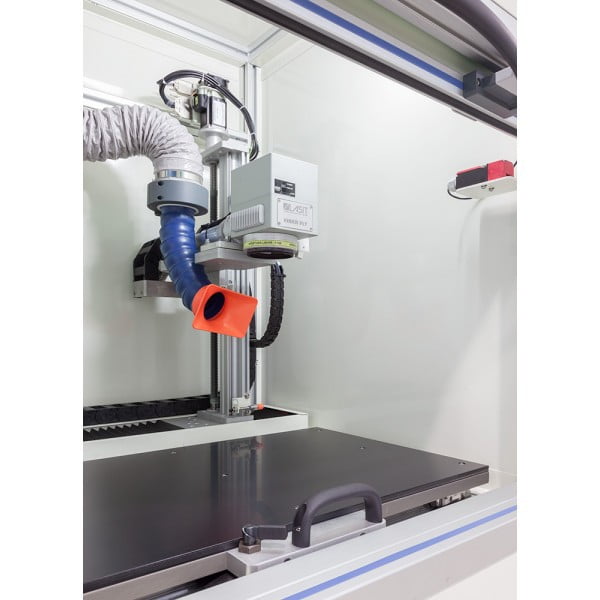

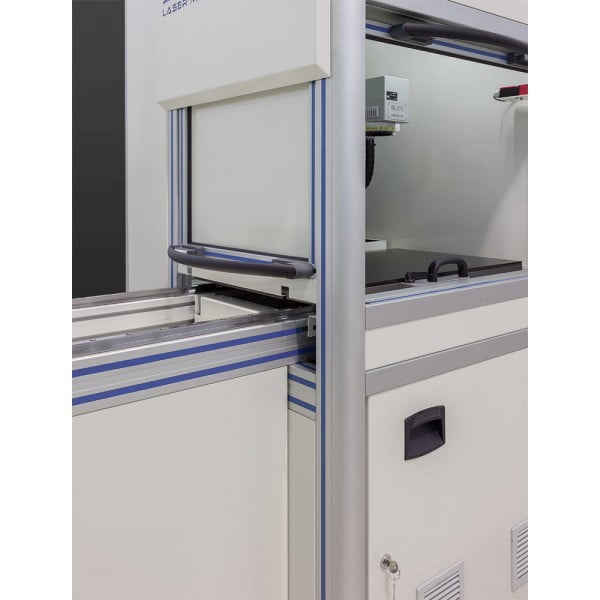

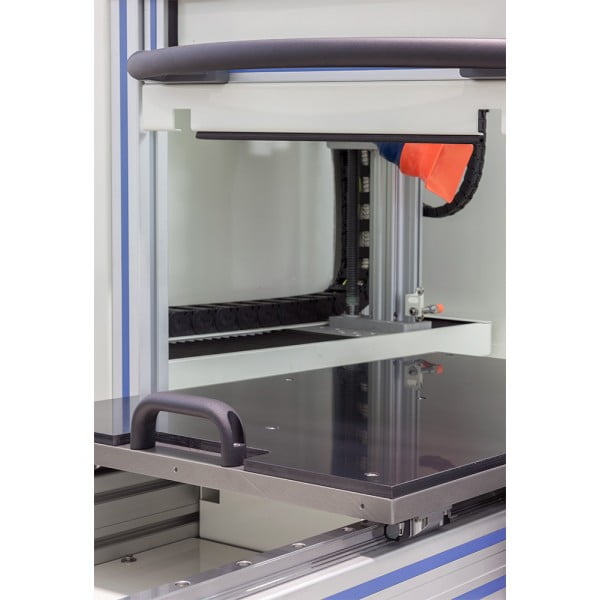

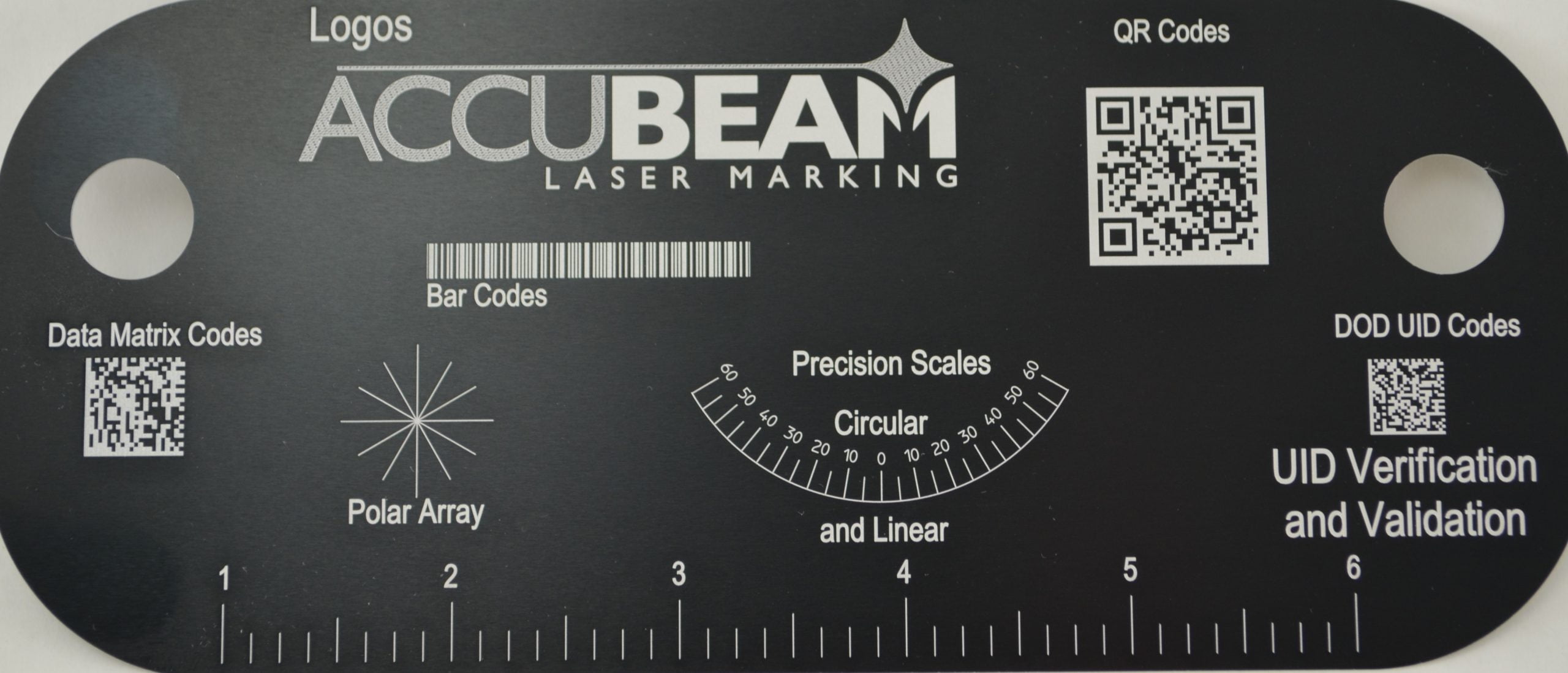

The marking TowerSlideX is a combination of the laser marking machine TowerMarkX. Produced and designed for those who have large production requirements and, above all, need to make the incision on particular designed and otherwise difficult to charge to the internal machine. The machine comes from the classical TowerMarkX with a structure, more robust and with the addition of a block side to the sliding plane. The loading system consists of a side stand with a carriage that slides on guides star. The carriage is operated by hand and has two end stops which allow the precise positioning and clamping to avoid movements especially during loading. The part is loaded with a hoist, and then pushed by hand in the marking cabin. At this point the laser can mark in the central part of ø220mm or 600mm long x 220mm. The floor is made with a sheet of hardened steel and has a grid of holes to facilitate the positioning of the part to the stop. The loading area is 1000mm wide so as to avoid moving the part close to the structure of the machine which could cause collisions due to reciprocation. The machine is designed to mark parts up to 700mm (depending on the width of the door), 450mm (depending on the depth of the machine) and 600 mm in height. The maximum weight evenly distributed on the marker is 350 kg. The block is loaded on a steel plate that slides on guides Star/Rexroth and which is pushed by hand in the marking cabin or through a sliding side door upwards compensated with a load balancer for a convenient opening/closing.

Download the brochure