FiberFly Green Laser source

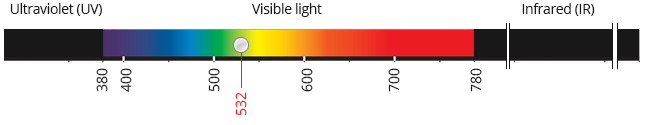

The FiberFly Green system uses the same innovative technology of the FiberFly system (active fiber doped with Ytterbium) with the integration of a duplication crystal wavelength. The pulse duration of the FiberFly Green laser is 532 nm. The minimum duration is 1 ns and the working frequency is 600 kHz. The FiberFly Green life expectancy is more than 100,000 hours of on time marking due to the “single emitter” diodes and the fully integrated construction of the optical components. Each laser has an interference filtration systems which provides additional protection against over voltages and power blackouts. The effectiveness of this filtration system is verified by a noise generator. The FiberFly Green system is ideal for marking opaque, translucent and transparent plastic materials. Many of these materials that can be laser processed are used in the solar/photovoltaic industry, backlit “night & day” buttons and panels as well as micro-machining type applications.

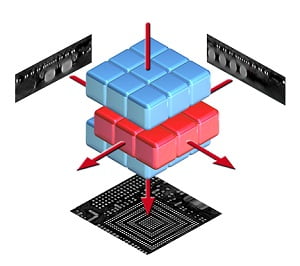

Second Harmonic Generation (SHG) uses a wavelength that is half of the typical 1064 nm wavelength. 532 nm falls into the visible spectrum and is green in colour. This wavelength is produced by transmitting a 1064 nm wavelength through a nonlinear crystal that reduces the wavelength by half. A YVO4 medium is normally used because the characteristics of the beam are well suited for intricate processing.

Typical characteristics of 532 nm wavelength range lasers

• High absorption rates in materials that do not react well with typical IR wavelengths and those that reflect IR light such as gold and copper.

• Intricate processing is possible because of a smaller beam spot than IR lasers.

• Transparent objects are typically not able to be processed.

• High peak power without large amounts of heat transfer is ideal for micro machining and intricate designs.

Download the brochure