FlyAir Green laser source

FlyAir Green is a solid state laser marking (active material YVO4 ), with a pumping axial and duplication crystal of the laser beam inside the cavity. The laser beam that is generated has a wavelength of 532nm and is characterized by green light. The laser module is completely sealed, assembled and pre-aligned in a white room. The FlyAir Green system is made up of two bodies connected through a steel shroud: a drawer that contains the management electronics and a group of components by including the laser source and the scanning unit. This shroud is essential for the protection of the cables and prevents damage caused by bending or accidental pressure or crushing to the shroud. The system is air cooled to ensure a constant temperature – the diode is mounted on a Peltier cell. This type of laser is ideal for all plastics marking; transparent parts in general, and for laser processing in the solar/photovoltaic industry.

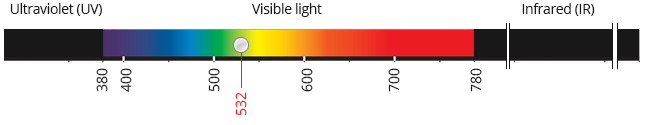

Wavelength: 532 nm

Second Harmonic Generation (SHG) uses a wavelength that is half of the typical 1064 nm wavelength. 532 nm falls into the visible spectrum and is green in colour. This wavelength is produced by transmitting a 1064 nm wavelength through a nonlinear crystal that reduces the wavelength by half. A YVO4 medium is normally used because the characteristics of the beam are well suited for intricate processing.

Typical characteristics of 532 nm wavelength range lasers

• High absorption rates in materials that do not react well with typical IR wavelengths and those that reflect IR light such as gold and copper.

• Intricate processing is possible because of a smaller beam spot than IR lasers.

• Transparent objects are typically not able to be processed.

• High peak power without large amounts of heat transfer is ideal for micro machining and intricate designs.

Download the brochure