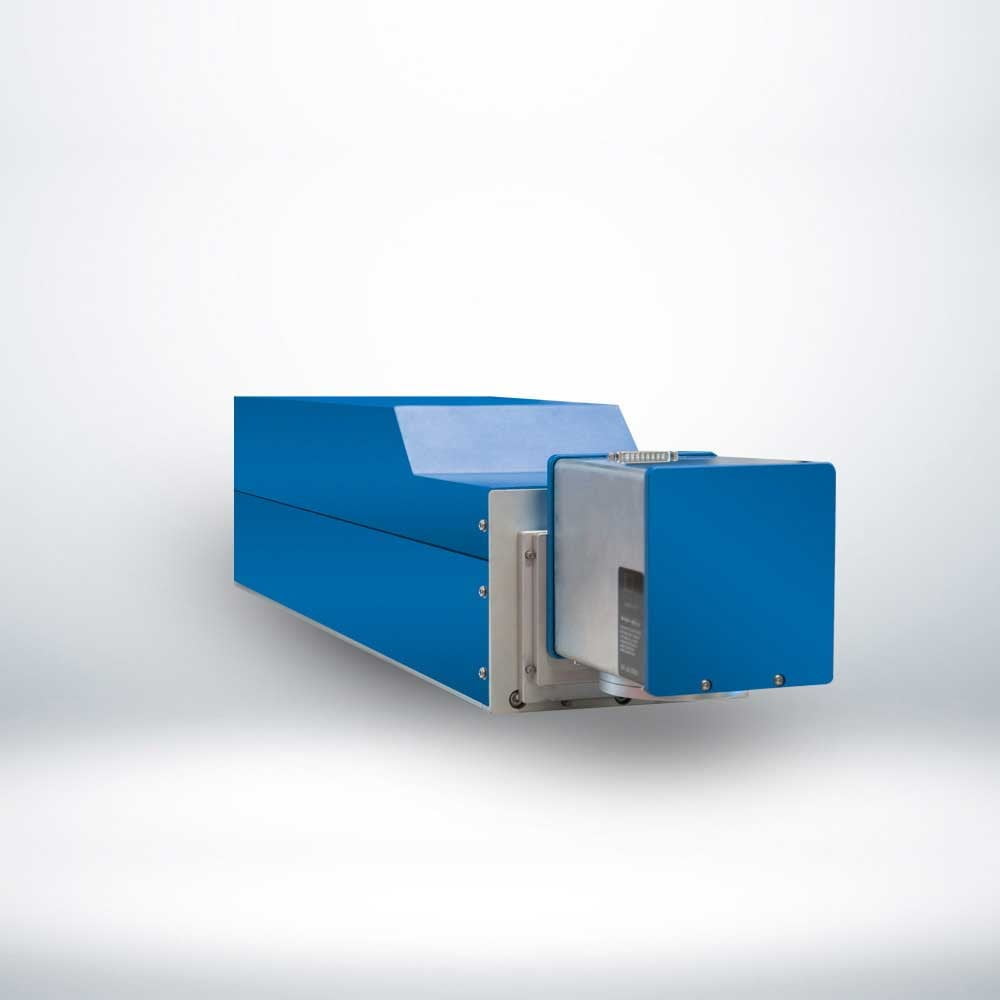

FlyCO2 laser source

Description

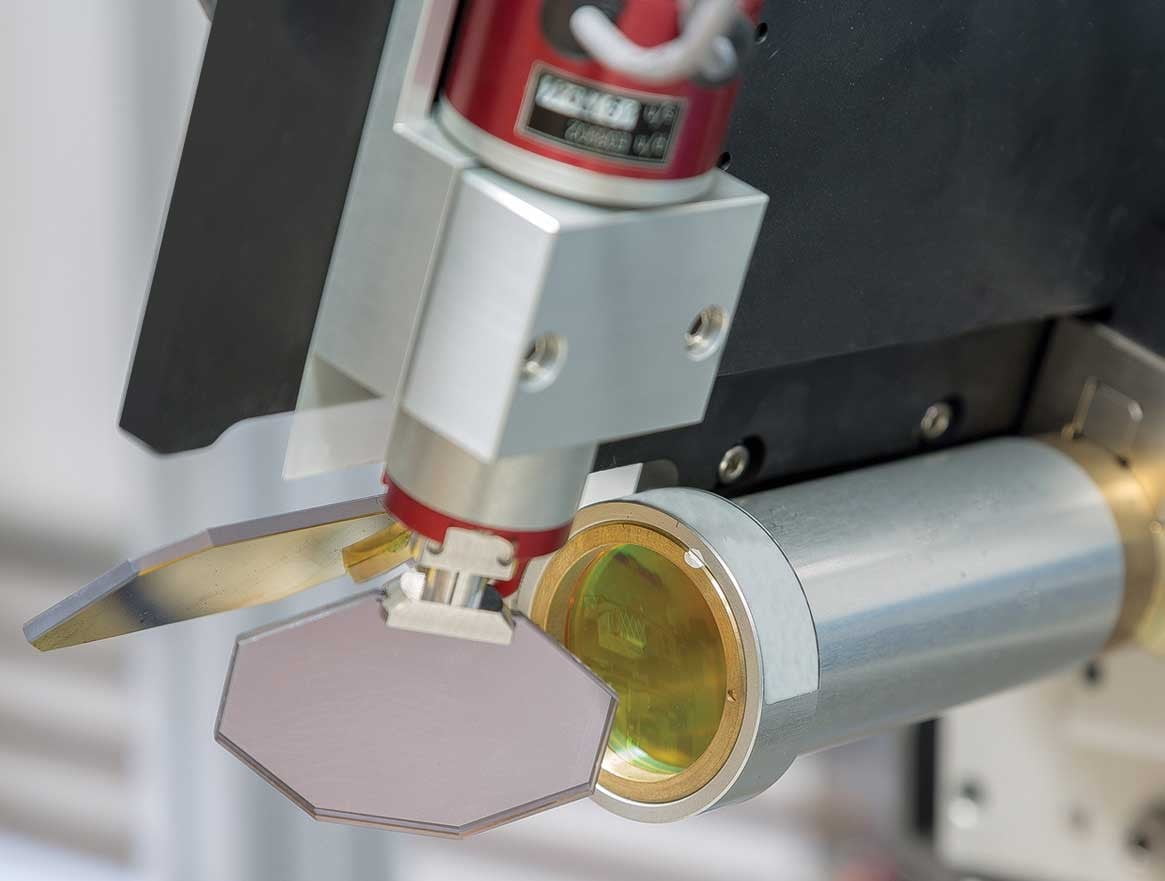

FlyCO2 is the solution for laser marking plastic and natural materials such as plexiglass, paper, wood, stone, textiles, and marble. The laser machine is extremely compact, modular and can fully integrated into any production line. The laser marking system is designed for high productivity while at the same time reducing operation costs. It can be completely integrated into productions lines to interface with existing PLC systems with communication via RS232 or TCP/IP available with the Client/Server design and the use of digital signals. According to the power/model, the source is of a sealed type and then the supply with external gas is not necessary. When the source is semi-sealed, a refill can be simply with the replacement of a pressurized canister that provides the proper mixture of gases. The current CO2 laser systems in production range from 10W to 70W with both air cooed and water cooled depending on the power. Depending on the specific application, such as marking, annealing cutting, sintering, drilling, deep engraving, LASIT offers a broad range of lasers. This is an RF source with the resonator integrated in the laser tube. The scanning unit is available with two or three axes. The two axis with a flat field lens or the three axis with a prescan lens with a dynamic Z. The two-axis scanning unit uses a pair of high speed and high accuracy galvanometers, with the drivers and the control electronics – in SMT technology – integrated inside the head itself which is also sealed to prevent mirror contamination.

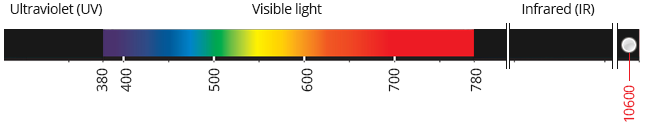

Wavelength: 10600 nm

CO2 lasers have a wavelength that is 10 times longer than a YAG,YVO4 or Fibre laser.

This is the longest wavelength among widely used industrial lasers. CO2 lasers, as the name implies generates the laser medium through stimulation of CO2 gas.

Typical characteristics of 10600 nm wavelength range lasers

• Not absorbed well by metals

• Melting and burning occur due to the long wavelength and transfer of heat.

• Processing transparent objects such as glass and PET are possible.

• Contrast printing and discolouration are generally not possible with a CO2 laser.

Download the brochure