Surtronic R-150 - Taylor Hobson

Surtronic R-150 – Taylor Hobson is an equipment for the measurement and analysis of shape, circularity and advanced harmonics. Robust and accurate, the equipment is ideal for any inspection room.

The Surtronic R150 offers a flexible solution to roundness and form requirements with a variety of software options and application-specific accessories, along with fixtures that can be tailored to your specific needs.

Key features

- Speed – Measure 3 parts/min. including set-up

- Precise results – ±25 nm spindle accuracy

- Robust and reliable – Suitable for 24/7 operation

- Ease of use – Touchscreen software

- Advanced analysis – Packages for bearings and automotive applications.

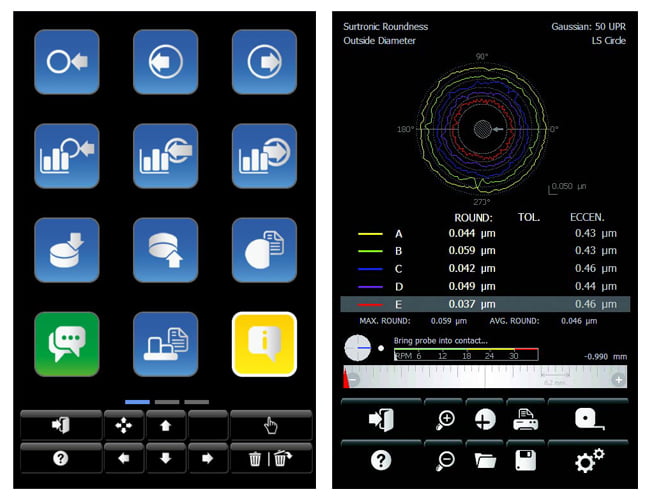

Surtronic R-150 powered by New Windows 10 tablet

The Surtronic R-150 with Windows 10 tablet allows for wireless data transfer to networks. All measurement data can be saved with filetypes including PDF and PNG by using the easy to use software interface. The Windows 10 tablet with Gorilla Glass 3.0, is highly resistant to scratches and sharp contact damage. It provides up to a 4x improvement in scratch resistance when compared to other aluminosilicate glasses.

Applications includes

- Bearings – Races, Balls, Needles and Rollers

- Automotive – Valves, Con Rods, Pins and Brake discs

- Grinding, turning, milling and honing

- Process Control – Grinding, Turning, Milling and Honing

- Other – Aerospace, Hydraulics, Industrial, Medical and Dental.

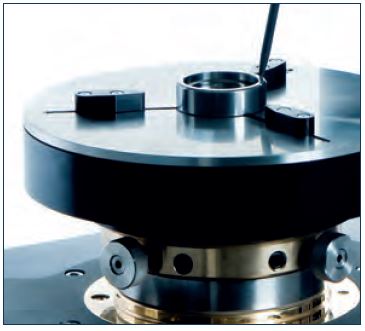

Patented RapidCentre™

RapidCentre™ avoids valuable cycle time being lost on manual part centring. On most parts precision results are achieved following a very simple and fast loading procedure. Now roundness measurements can be made in less than 30 seconds including part loading, centring, measurement, analysis and results display.

Download the brochure