FiberFly laser source

FiberFly laser uses the most innovative technology at with active fiber doped with Ytterbium. It is the ideal laser solution for precision laser engraving, marking, micro-machining and cutting of plastic and metal materials. The fiber technology has provided extraordinary leaps in laser technology: The expected laser life provides more than 100,000 hours of marking due to the use of “single emitter” diodes as well as the fully integrated design and construction of the optical components. In order to guarantee additional protection against overvoltage or power blackouts, LASIT an interference filtration system. This design is standard on each FiberFly system that is built. The real effectiveness is verified by a noise generator. Moreover, a flexible stainless steel tube protects and guides the connection cables as well as the optical fiber. An additional layer of steel armour cabling further protects the cables. This tube of diameter 25mm minimizes the possibility of accidental breakage and it creates additional protection against any electromagnetic interference or electrostatic discharge. The marks created with the FiberFly system are accurate, indelible and have no environmental impact whatsoever, unlike inks and chemicals.

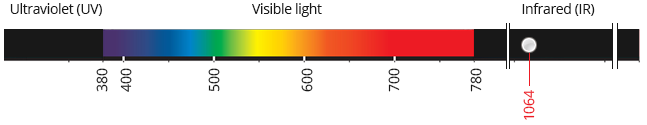

Wavelength: 1064 nm

The IR wavelength which is an abbreviation for Infrared Ray is the most versatile wavelength of light for laser processing.

As the name implies, IR is the spectrums outside of red, which are invisible to human eyes (i.e. longer than 780 nm).

Typical characteristics of 1064 nm wavelength range lasers

• A wide range of processing applications from resins to metals

• Cannot process transparent objects like glass as the laser passes through such objects.

• Creates contrast on resins easily.

Download the brochure