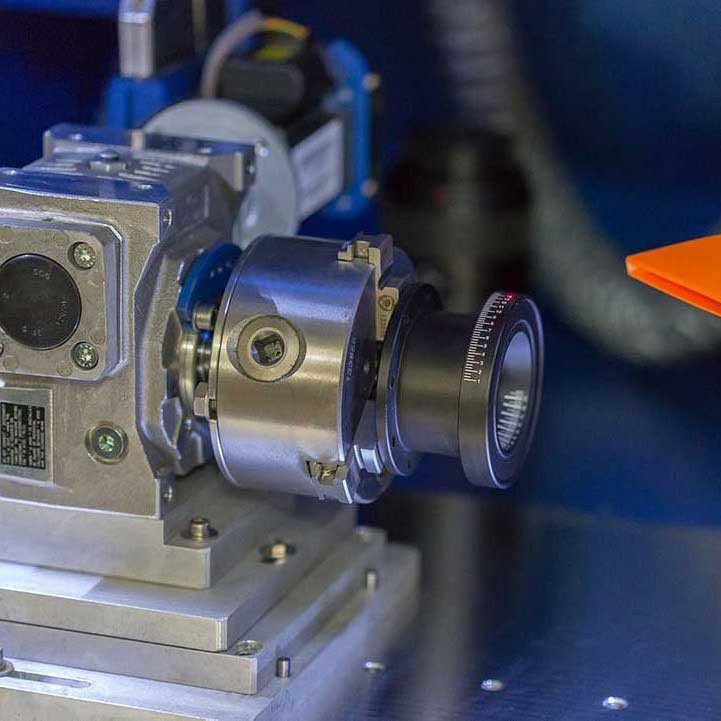

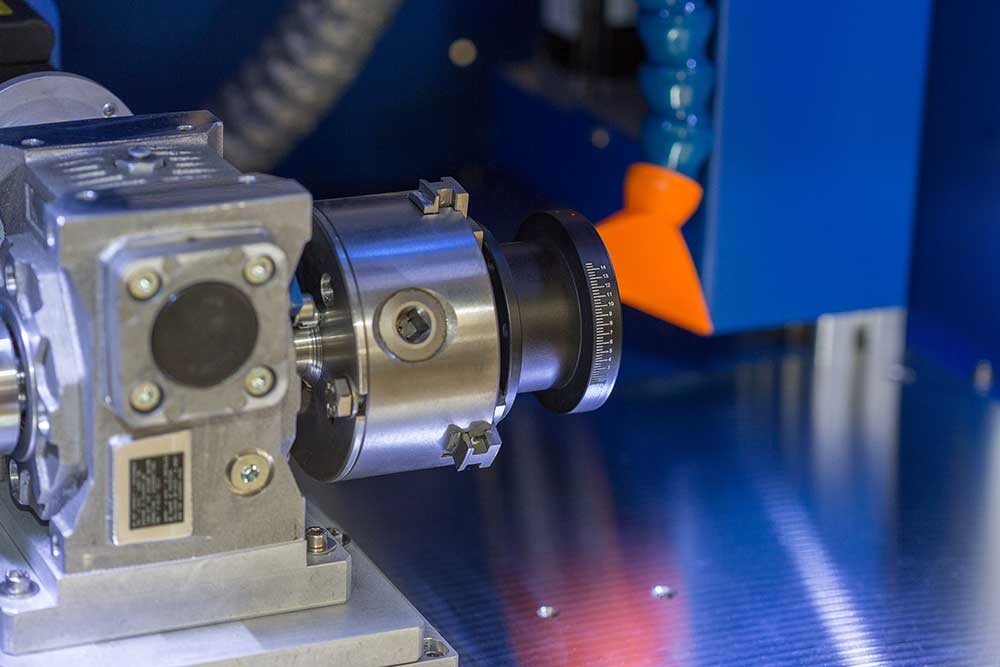

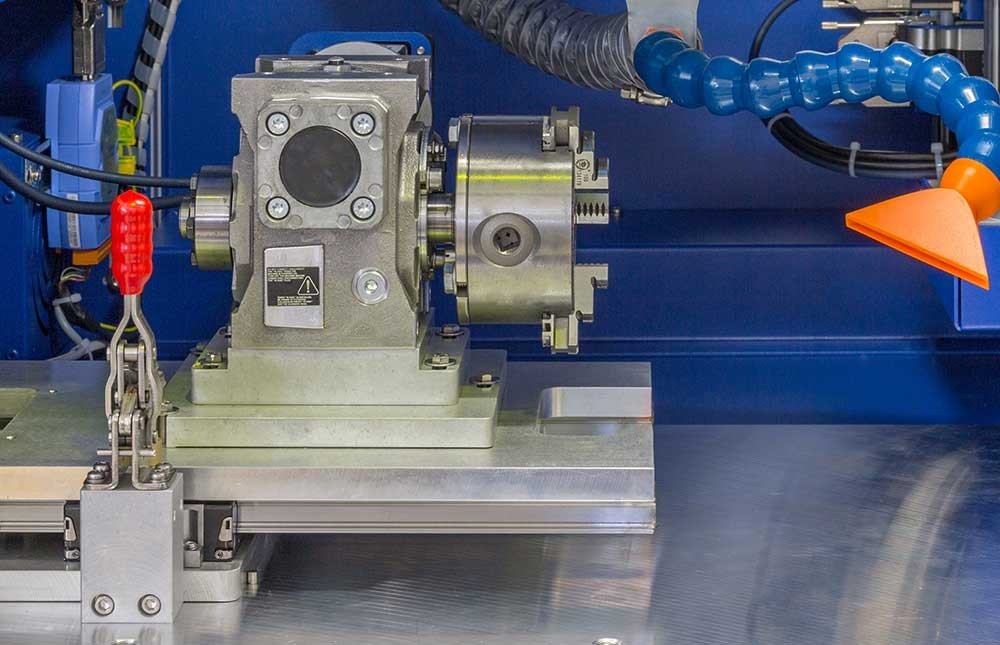

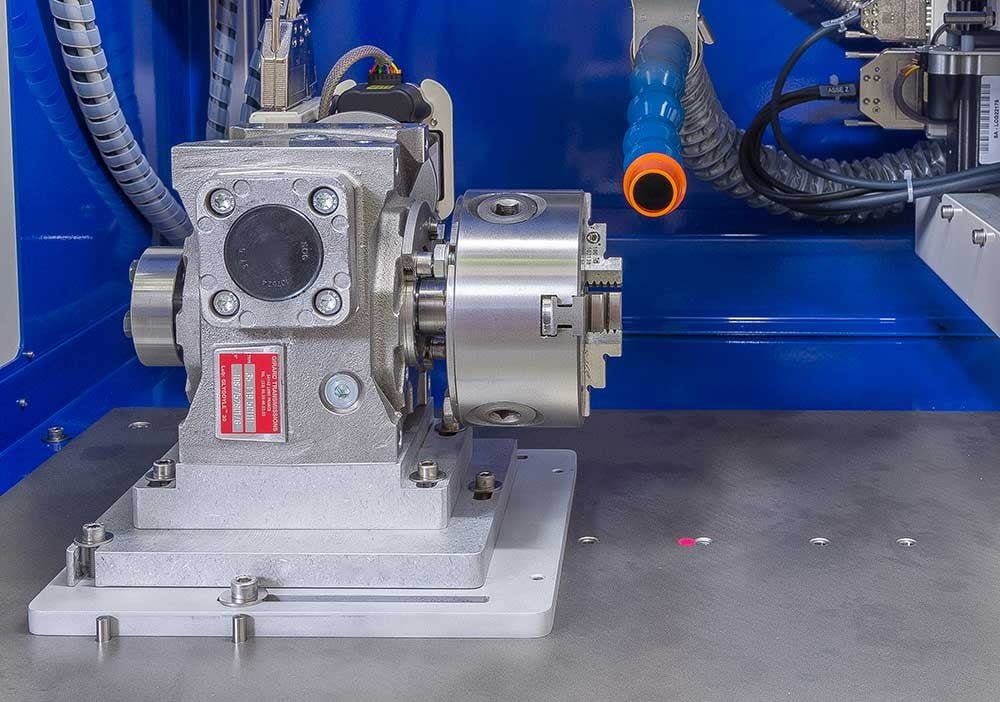

W rotating axis

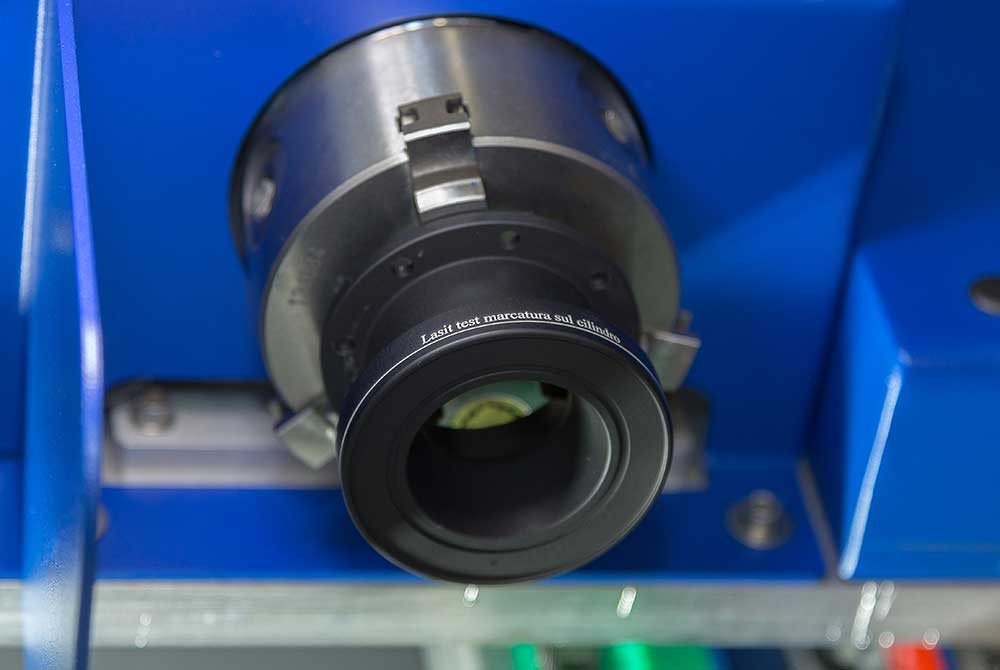

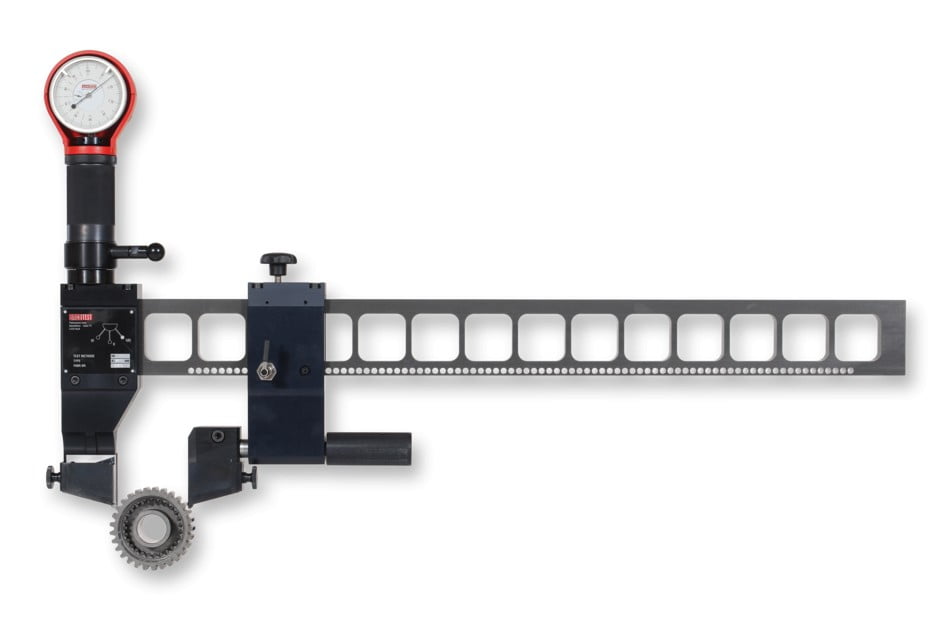

The rotation axis (W) allows for laser marking on cylindrical parts with ease and precision. It offers the highest resolution and accuracy with seamless marking or wrapping of logos/drawings around the circumference with 39,936 steps/revolution. The W axis provides for complete rotational marking in conjunction with the programmable Z axis for any diameter. Both the W and Z axes are programmed to work in conjunction with one another around any size diameter. The heart of the mechanism is the worm gear, which is precision ground and finely machined offering smooth, consistent movement with no interference.

The assembly is completely sealed with high-level components, making for long product life. The rigid, robust construction optimizes the precision in rotation even with heavy or unbalanced loads with high inertia. A tailstock feature is available for laser marking long, thin or very heavy parts. The tailstock is mounted on precision ground guides that provide forward and backward movement of the chuck itself. The tailstock lock offers great flexibility and can be either mechanical (manual) or pneumatic. The rotary is available as a standard 3-jaw chuck or a 6-jaw chuck. Special rotaries are also available for higher loads and larger diameters.

Download the brochure