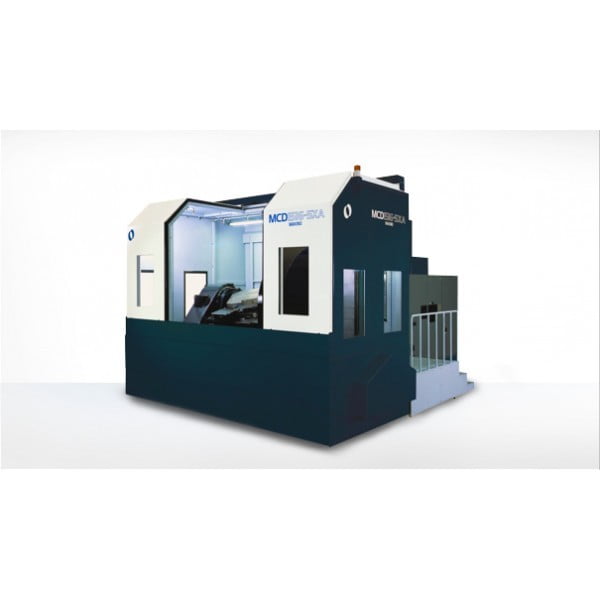

Laser marking system - Lasit RotoMark XL

RotoMarkXL is the first laser marking machine that combines the advantage of the load/unloading at the same time. The system is available with 4 to 8 positions for marking. The table diameter is available up ot 1500mm and can include an X axis for positioning of the laser head. The X axis stroke can be from 200mm up to 500mm providing a marking area from 150x650mm or 280x780mm depending on the appropriate lens. RotoMarkXL is ideally designed for high productivity for large arrays of parts to be marked at one time. It can also be used for marking single parts or larger parts. The machine can be operated both automatically with the index table or manually from the back door. The table has a rugged industrial cam mechanism with a long life which provides high speed marking, precision and repeatability over time. There are optional optical barriers available to protect the table. The programmable Z axis, controlled by the FlyCAD software, together with the pneumatic door has a long stroke which provides for marking parts from 0 to 400mm in height. The exhaust fan is inside the marking system. A proprietary pneumatic device approaches the nozzle as it marks a part creating optimal efficiency in marking. The operating panel can be adjusted and is positioned close to the workstation either in the front or in rear depending on customers requirements.

Download the brochure