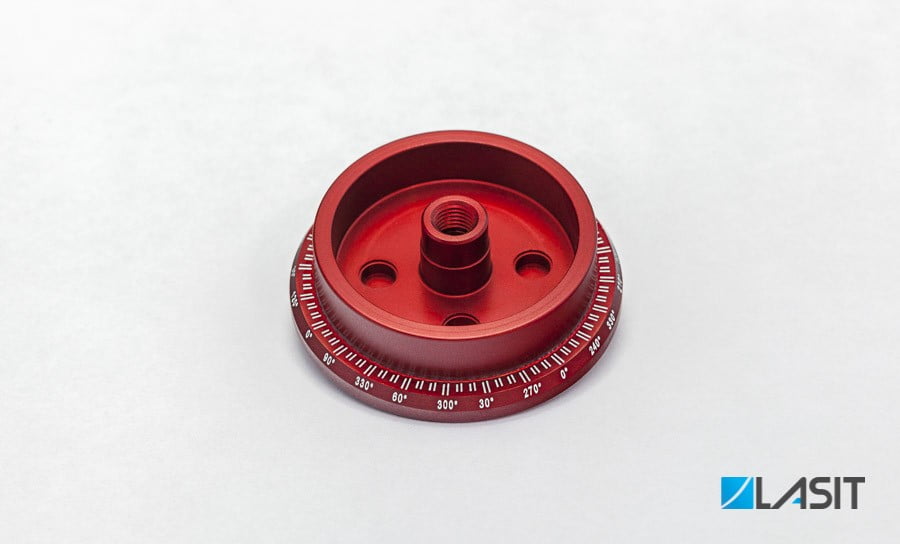

Laser marking system Lasit FlyGear

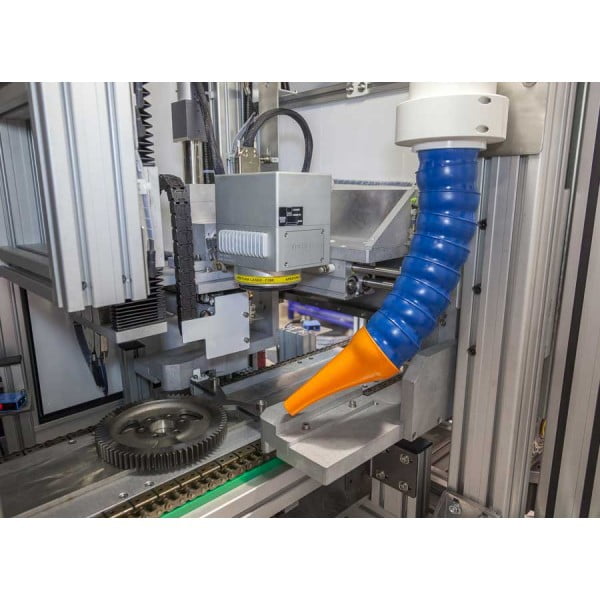

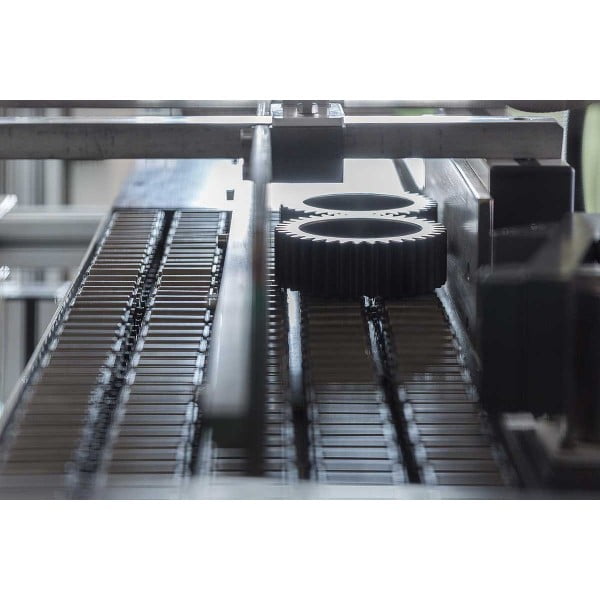

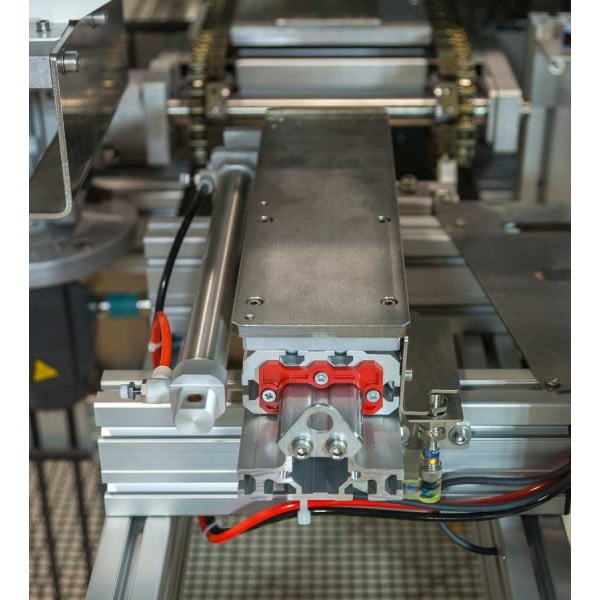

FlyGear is a specially designed automated system for laser marking conical gears. The gantry configuration is equipped with programmable XYZ motorized axes with a stroke of 800x600x250mm and with an optional rotating scan head. The machine is also equipped with two loading and unloading stations located on opposite sides. This ergonomic design provides an ease of use for repetitive jobs. The loading and unloading is with two motorized tables with a rack mechanism. This enables the operator to work on two stations independently from one another. The control cabinet and the PC box are both air-conditioned to optimize performance even in extreme climates. The system has a manual frontsliding door with and inspection viewing glass. The operator is protected by side barriers. He is able to load parts, selecet a corresponding program and start up the marking cycle. The motorized table then advances into the marking chamber with a pneumatic door that closes. It is possible to automatically mark both the shaft and the gear on the head. At the end of this cycle the second pneumatic door opens and the table comes out and parts are ready to unload.

Download the brochure